Introduction to Cryostat Reaction Baths

Functionality and Components

Cryostat reaction baths are integral to maintaining precise temperatures in scientific experiments, utilizing a combination of resistance heating and compressor cooling mechanisms. These systems are meticulously controlled by PID (Proportional-Integral-Derivative) controllers, which ensure that the temperature remains within a narrow, predetermined range. This level of control is crucial for experiments that require consistent environmental conditions.

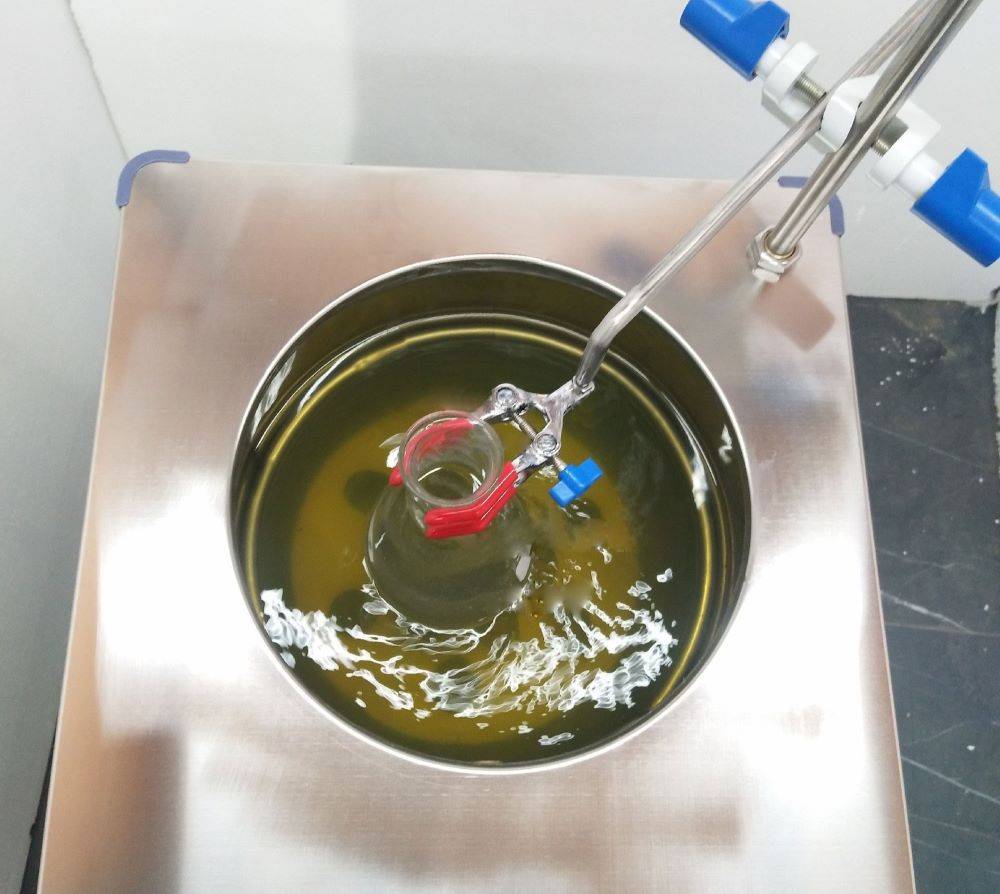

In addition to temperature regulation, cryostat reaction baths are equipped with magnetic stirring capabilities. This feature allows for the uniform mixing of substances within the bath, ensuring that any reactions occurring inside are evenly distributed and consistent. The combination of these functionalities—precise temperature control and efficient mixing—makes cryostat reaction baths indispensable in various scientific applications, from chemistry to material science.

To further illustrate the complexity and precision of these systems, consider the following table:

| Feature | Description |

|---|---|

| Resistance Heating | Utilizes electrical resistance to generate heat, controlled by PID systems. |

| Compressor Cooling | Uses a compressor to lower the temperature, balancing the heating effect. |

| Magnetic Stirring | Ensures uniform mixing of substances within the bath. |

| PID Controllers | Advanced control systems that maintain precise temperature settings. |

These components work in harmony to provide a stable and controlled environment, essential for the accuracy and reliability of scientific experiments.

Variations in Heating Medium

Switching the heating medium from aqueous solutions to oil-based systems can significantly elevate the operational temperature limit of cryostat reaction baths to 99℃. This change is not merely a technical upgrade but also a strategic move to enhance the bath's performance and safety.

One of the primary advantages of using oil as a heating medium is its superior thermal stability compared to water. Oil can withstand higher temperatures without the risk of boiling or evaporating, which is crucial for maintaining a stable environment for delicate experiments. This stability is particularly important in applications where precise temperature control is necessary, such as in biochemical reactions or material science studies.

Moreover, the transition to oil-based heating systems is accompanied by robust safety mechanisms. Key safety features include over-temperature and under-temperature alarms, which serve as critical safeguards against operational anomalies. These alarms are designed to alert operators immediately if the temperature deviates from the set parameters, ensuring prompt corrective actions can be taken to prevent equipment damage or experimental failures.

In summary, the shift to oil-based heating media not only extends the operational temperature range but also bolsters the safety and reliability of cryostat reaction baths, making them more suitable for high-temperature applications and critical experiments.

Corrosion in Cryostat Reaction Baths

Material Susceptibility

The construction materials of cryostat reaction baths are pivotal in determining their durability and performance. These baths are predominantly crafted from aluminum alloys, a choice that offers a balance between lightweight design and structural integrity. However, this material selection introduces a significant vulnerability: galvanic corrosion.

Galvanic corrosion occurs when two dissimilar metals with different electrochemical potentials come into contact within an electrolyte, such as the reaction medium in a cryostat bath. In this scenario, the aluminum alloy acts as the anode, which corrodes preferentially. This process can be accelerated by factors such as the presence of chlorides, which are often found in aqueous solutions used in these baths. The resulting corrosion not only compromises the structural integrity of the bath but also introduces impurities that can affect the precision of experimental results.

To mitigate these risks, it is essential to consider alternative materials or protective coatings that can reduce the susceptibility to galvanic corrosion. For instance, the use of stainless steel components in critical areas, such as the stirrer and connectors, can help isolate the aluminum alloy from direct contact with other metals, thereby minimizing the risk of galvanic action. Additionally, employing coatings that are resistant to both chemical and electrochemical attack can provide an added layer of protection.

Understanding and addressing the material susceptibility of cryostat reaction baths is crucial for maintaining the longevity of the equipment and ensuring the accuracy of scientific experiments. By carefully selecting and treating materials, it is possible to significantly reduce the incidence of galvanic corrosion and its detrimental effects on both the equipment and the experimental outcomes.

Impact on Equipment and Experiments

Corrosion in cryostat reaction baths significantly diminishes the operational lifespan of critical equipment and undermines the precision of scientific experiments. This degradation manifests in several detrimental ways, each posing unique challenges to the integrity of the experimental setup.

One of the most immediate effects is pump corrosion. The pumps, essential for circulating the reaction medium, are often made from materials that are susceptible to corrosion. Over time, this corrosion can lead to reduced efficiency, mechanical failure, and even complete pump breakdown. Such failures not only disrupt ongoing experiments but also necessitate costly repairs or replacements.

Similarly, sample rack corrosion compromises the reliability of experimental results. Sample racks, which hold crucial specimens during the reaction process, can become corroded, leading to contamination or loss of samples. This not only affects the accuracy of the data collected but also necessitates the repetition of experiments, thereby increasing both time and resource expenditure.

Another significant issue is pipe clogging. Corrosion products can accumulate within the pipes, obstructing the flow of the reaction medium. This clogging can lead to uneven temperature distribution, which is critical in maintaining the precise conditions required for many experiments. The resulting inconsistencies can skew experimental outcomes, rendering the data unreliable.

In summary, the impact of corrosion on cryostat reaction baths extends beyond mere equipment degradation; it fundamentally affects the veracity and reproducibility of scientific experiments. Addressing these corrosion-related issues is therefore not just a matter of maintenance but a crucial step in ensuring the integrity of the experimental process.