Introduction to Rotovap in Molecular Gastronomy

Rotovap, short for rotary evaporator, is a laboratory equipment used for separating solvents from samples through the process of evaporation. It is a popular tool in the molecular gastronomy field for extracting and concentrating flavors and aromas from delicate ingredients such as herbs, fruits, and spices. By using a rotovap, chefs and mixologists can enhance the taste and aroma of their dishes and beverages, providing a unique and elevated culinary experience. The process of rotovap distillation involves heating the sample in a flask and rotating it at a controlled speed, which creates a thin film and increases the surface area for evaporation.

Table of Contents

How Rotovap Distillation Works

Rotovap distillation is a technique used in molecular gastronomy to extract essential oils, flavors, and aromas from foods and beverages. This method is widely used in the food industry to create unique and intense flavors that are not achievable through traditional cooking methods. Here is how rotovap distillation works.

Step 1: Lowering the Pressure

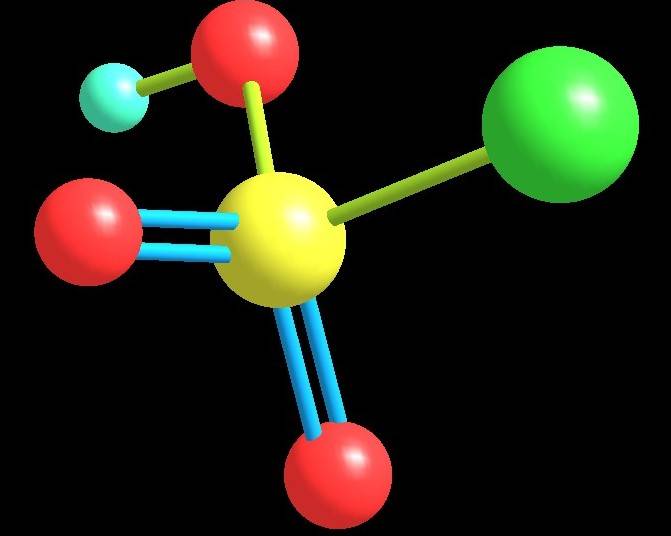

Rotovap distillation works by using a vacuum pump to lower the pressure inside a flask containing the liquid to be distilled. This step is critical as it lowers the boiling point of the liquid significantly.

Step 2: Heating the Flask

After the pressure has been lowered, the flask is then heated, and the liquid starts to evaporate. The heat applied to the flask depends on the type of liquid being distilled. This heating process is done gently to avoid damaging the delicate flavors and aromas.

Step 3: Condensing Vapor

The vapor created in the flask during the heating process is then condensed in a separate flask, leaving behind the concentrated flavor or aroma. This step is achieved using a condenser that chills the vapor, recondensing it into a liquid.

Step 4: Separating the Volatile Compounds

By lowering the pressure in the flask, the volatile compounds are separated from the non-volatile ones, thus creating a more intense and pure flavor. This process works by separating the volatile compounds from the non-volatile ones, thus creating a more intense and pure flavor.

Step 5: Collecting the Concentrate

The final step is collecting the concentrate in the receiving flask. The concentrate is pure and fresh, unaffected by the flavor-killing effects of too much heat, which is particularly beneficial when working with ingredients such as fruits and herbs.

In summary, rotovap distillation is a gentle, non-destructive method of extracting flavors and aromas from foods and beverages. Its ability to extract flavors and aromas without altering the texture or appearance of the food makes it a versatile and valuable tool in the culinary world. Rotovap distillation is an essential technique for chefs and food scientists who want to explore new flavors and create innovative dishes or beverages.

Benefits of using a rotovap for flavor extraction

Rotavapors have become increasingly popular in molecular gastronomy due to the benefits they offer for flavor extraction. Below are some of the benefits of using a rotovap for flavor extraction:

1. Increased efficiency

Rotavapors allow for the efficient extraction of volatile flavor and aroma compounds from food samples. The use of vacuum technology and precise temperature control within a rotovap ensures that the extraction process is efficient and accurate.

2. Precise control over temperature and pressure

One of the most significant advantages of using a rotovap for flavor extraction is the ability to control temperature and pressure precisely. By controlling these variables, it is possible to extract delicate and complex flavors without damaging them or altering their chemical composition.

3. Ability to extract delicate and complex flavors

The gentle nature of rotovap extraction makes it possible to extract delicate and complex flavors that are often difficult to extract using other methods. The precise temperature control and vacuum technology ensure that the flavors are extracted without the need for excessive heat that could potentially damage the flavors.

4. Creation of unique and innovative flavor combinations

Rotavapors allow for the creation of unique and innovative flavor combinations by combining different extracted flavors. By extracting individual flavors and then combining them in different ratios, chefs can create new and exciting flavor profiles that were not possible before.

5. Improved safety

Using a rotovap for flavor extraction is a safer method compared to other methods that require the use of high heat or harsh chemicals. The gentle nature of the extraction process means that there is less risk of damage to the flavors or the food sample being used.

6. Better quality and purity of extracted flavors

Rotovap extraction ensures that the extracted flavors are of high quality and purity. This is because the vacuum technology and precise temperature control prevent the extraction of unwanted compounds and impurities that could affect the flavor and aroma of the extracted sample.

In summary, the use of rotavapors for flavor extraction has revolutionized the culinary industry by providing chefs with a new tool for flavor extraction and experimentation. The benefits of using rotovapors for flavor extraction include increased efficiency, precise control over temperature and pressure, ability to extract delicate and complex flavors, creation of unique and innovative flavor combinations, improved safety, and better quality and purity of extracted flavors.

Rotovap's Use in Cocktails and Beverage Industry

The Rotovap, also known as the Rotary Evaporator, is a device widely used in the cocktail and beverage industry to enhance the flavor and aroma of drinks. This device works by using a vacuum pump to reduce the pressure above a liquid, causing it to boil at a lower temperature. This allows the liquid to be heated gently, preserving delicate flavors and aromas that would be destroyed by more aggressive heating methods.

How Rotovap Works in Flavor Extraction

By distilling liquids under vacuum, the Rotovap can extract essential oils and other flavor compounds that are usually lost during conventional distillation. It can produce a more intense and complex flavor profile in cocktails and beverages. The device is particularly useful for creating infused alcohols and syrups, as well as for producing flavored waters and juices.

Benefits of Using Rotovap in Cocktail and Beverage Industry

The use of Rotovap in the cocktail and beverage industry is on the rise, as bartenders and mixologists seek to create unique and innovative drinks that offer a sensory experience beyond taste alone. The Rotovap is particularly useful for creating unique and complex cocktails and other alcoholic beverages. The device is also used to remove unwanted flavors or aromas from ingredients, such as removing the bitterness from certain herbs or fruits.

Examples of Rotovap's Applications in the Industry

At Artesian, located in The Langham hotel in London, a minimalist menu was created which depends highly on the Rotovap. One such iconic drink of theirs is a cognac blended with green coffee. This drink once through the Rotovap becomes a crystal-clear extract as the colors and tannins from the ingredients are removed but the coffee and cognac flavors are retained. This crystal-clear extract is then served on a clear ice cube, in line with the minimalist spirit.

Empirical Spirits, a Copenhagen-based microdistillery, is another example. They use large-scale low-temperature distillation to extract the flavors and essences of ingredients they source. One of their celebrated spirits is the Ayuuk which involves the use of the rare Pasilla Mixe Mexican chile from which smoke, earthiness, and darkness are distilled and the spice is left out.

The Cost of Rotovap in the Industry

However, the Rotovap is an expensive affair, costing upwards of $11,000 for the full Rotovap setup. But many bars are ready to take the plunge to enhance the drinks experience for their consumers. It definitely seems like a cost that will pay off in serving the best beverages with intense flavors and exciting fusions.

The Grey Area Regarding Ownership and Usage of Rotovap

While the Rotovap seems irresistible, there exists a grey area regarding ownership and usage of the same across different premises. Distillation at home or at a bar is illegal without a license, and many bars currently prefer water distillation since that helps them escape the legal tightrope of alcohol distillation. It is therefore recommended that one should consult users of Rotovaps before deciding on buying one.

In conclusion, the Rotovap has become a valuable tool for the cocktail and beverage industry in creating unique and complex flavors that enhance the drinking experience. The device has applications in flavor extraction, removing unwanted flavors, and creating infused alcohols and syrups. Although it is a costly investment, the benefits are well worth it for bars and mixologists seeking to provide a sensory experience beyond taste alone.

Safety and Legal Concerns with Rotovap Use

Rotavapor, or rotary evaporator, is a laboratory equipment commonly used in molecular gastronomy to extract essential oils and other aromatic compounds, which can elevate the flavor and aroma of food. However, the use of rotovap raises safety and legal concerns that should not be overlooked. Here are some important considerations to keep in mind:

Safety Concerns

Risk of Explosion: The use of flammable solvents with rotovap can pose a risk of explosion. Proper ventilation and handling procedures are essential to minimize the risk of accidents.

- Impact and Vibration: The rotovap is sensitive to impact and vibration, which can damage the machine or cause it to malfunction. Proper handling and placement of the machine are important to prevent accidents.

- Clearance Space: Ensure enough clearance around the rotovap so that its lifting mechanism has ample space to move.

- Splash and Contamination: Instances of substance splashes are inevitable during the distillation process. Enclosing the evaporating flask with either a splash or protection shield can prevent possible contamination and injuries.

Legal Concerns

- Regulation and Prohibition: Some essential oils and other aromatic compounds may be regulated or prohibited by law. Professionals in the field of molecular gastronomy should be aware of the legal implications of using rotavap and ensure compliance with the relevant regulations.

In summary, to ensure safety and legality when using rotovap, proper ventilation and handling procedures are essential, and it is important to be aware of the legal implications of using certain essential oils and aromatic compounds. By taking these precautions, professionals in the field of molecular gastronomy can continue to push the boundaries of flavor and aroma in the culinary world while upholding the highest standards of safety and compliance.

Conclusion and Future Applications

In conclusion, the rotovap is a valuable tool in the molecular gastronomy and beverage industry for extracting flavors and aromas. Its ability to distill liquids at low temperatures allows for the preservation of delicate flavors that would otherwise be lost through heat exposure. The rotovap's versatility also makes it a useful tool in other areas, such as the pharmaceutical and cannabis industries. As technology continues to advance, we can expect to see more innovations in the rotovap's design and application, leading to even more exciting possibilities for flavor extraction and experimentation.

Related Products

Related Articles

- What Is Multiple Effect Evaporator?

- How Rotary Evaporator Can Improve the Quality of Your Distillate

- How Rotary Evaporators are Revolutionizing Distillation

- The Importance of Water Distillation in the Laboratory: Ensuring Purity and Quality for Accurate Results

- Why Tap Water Chilling Is Not Enough for Your Rotavap