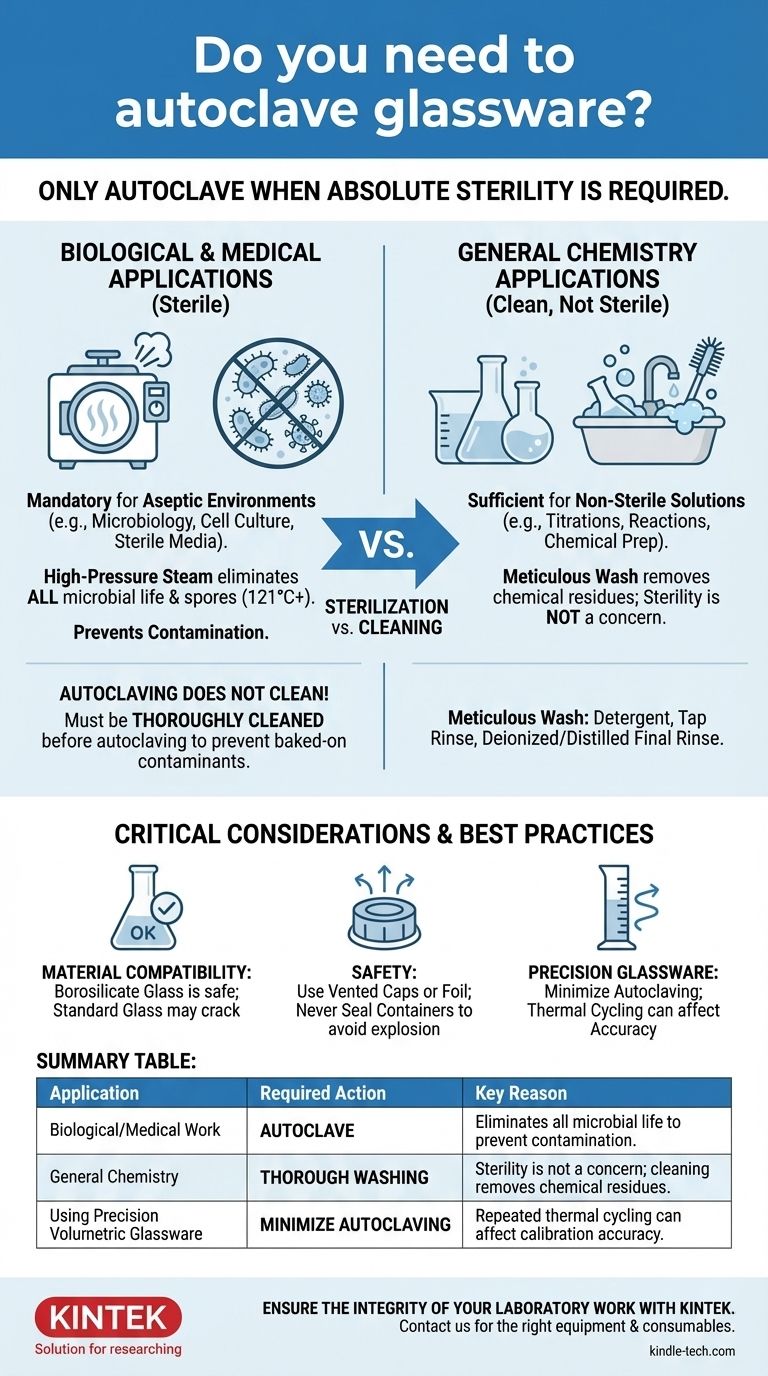

In short, you only need to autoclave glassware when absolute sterility is required. The necessity is dictated entirely by your application. For many common laboratory tasks, especially in general chemistry, a thorough cleaning is sufficient, but for any biological or medical work where microbial contamination is a concern, autoclaving is mandatory.

The core decision is not about cleaning, but about sterilization. Autoclaving uses high-pressure steam to eliminate all microbial life, a step that is critical for biological applications but unnecessary for many chemical procedures.

What an Autoclave Actually Achieves

To determine if you need to use an autoclave, it's essential to understand what it does and, more importantly, what it doesn't do.

The Principle of Sterilization

An autoclave is a machine that performs sterilization. It uses steam heated to very high temperatures (typically 121°C or higher) under pressure.

This combination of heat, steam, and pressure is lethal to all forms of life, including bacteria, viruses, fungi, and even highly resistant bacterial spores. The goal of autoclaving is to achieve a completely sterile state, free from any living microorganisms.

Distinguishing Sterilization from Cleaning

A common misconception is that autoclaving cleans glassware. It does not.

In fact, placing dirty glassware in an autoclave will bake the contaminants onto the surface, making them nearly impossible to remove later. Glassware must be thoroughly cleaned with detergents and rinsed before it is placed in an autoclave.

When is Autoclaving Glassware Necessary?

Your specific application is the only factor that determines whether you need to sterilize your glassware.

For Biological and Medical Applications

Autoclaving is non-negotiable for any work that requires an aseptic (sterile) environment.

This includes microbiology (culturing bacteria), cell culture (growing mammalian cells), molecular biology, and the preparation of sterile media or solutions for medical use. Failure to sterilize in these contexts will lead to contamination, invalidating experiments and posing potential safety risks.

When Simple Washing is Sufficient

For many general chemistry applications, sterility is not a concern.

If you are preparing chemical solutions, performing titrations, or running reactions where microbial life will not interfere with the outcome, a meticulous wash is all that is needed. This typically involves scrubbing with a lab-grade detergent, rinsing with tap water, and a final rinse with deionized or distilled water to remove mineral residue.

Understanding the Trade-offs and Best Practices

While effective, autoclaving is a harsh process that requires careful consideration to be performed safely and correctly.

The Prerequisite of Cleaning

Always ensure your glassware is visibly clean and has been thoroughly rinsed before autoclaving. Any residual biological material or chemical residue will be permanently baked onto the glass surface.

Material Compatibility

Most laboratory glassware, such as borosilicate glass (e.g., Pyrex, Kimax), is designed to withstand the thermal stress of an autoclave.

However, standard soda-lime glass (like a drinking glass) can crack or shatter. Furthermore, repeated autoclaving can affect the accuracy of volumetric glassware (e.g., graduated cylinders, volumetric flasks) due to thermal expansion and contraction.

Safety and Proper Operation

Never seal a container with a standard screw cap before autoclaving. The pressure buildup inside the container will cause it to explode. Use vented caps or cover openings with aluminum foil.

Always use autoclave indicator tape to verify that the cycle has reached the correct sterilization temperature.

Making the Right Choice for Your Goal

Use your specific application to guide your decision on how to prepare your glassware.

- If your primary focus is microbiology, cell culture, or preparing sterile reagents: Autoclaving is mandatory to eliminate microbial contamination and ensure the validity of your results.

- If your primary focus is general chemistry or preparing non-sterile solutions: A thorough wash with the appropriate detergent and a final rinse with purified water is sufficient and more efficient.

- If you are working with precision volumetric glassware: Minimize autoclaving, as repeated thermal cycling can compromise its calibrated accuracy.

Ultimately, choosing the right preparation method ensures the integrity of your work and the safety of your lab environment.

Summary Table:

| Application | Required Action | Key Reason |

|---|---|---|

| Biological/Medical Work (e.g., cell culture, microbiology) | Autoclave | Eliminates all microbial life to prevent contamination. |

| General Chemistry (e.g., titrations, reactions) | Thorough Washing | Sterility is not a concern; cleaning removes chemical residues. |

| Using Precision Volumetric Glassware | Minimize Autoclaving | Repeated thermal cycling can affect calibration accuracy. |

Ensure the integrity of your laboratory work with the right equipment and consumables from KINTEK.

Whether your application demands sterile glassware for sensitive biological assays or robust, clean labware for chemical processes, KINTEK provides the high-quality lab equipment and consumables you need. Our expertise helps you select the right tools for your specific protocols, ensuring safety and accuracy.

Contact us today to discuss your laboratory's requirements and discover how KINTEK can support your success.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- What is the necessity of using an autoclave for pre-treating culture media? Ensure Accurate Ag2O/TiO2 Testing

- What are the advantages of using an autoclave equipped with a stirring device for molten salt testing? Dynamic Accuracy

- What critical environmental conditions does a laboratory autoclave provide for evaluating wear resistance? - KINTEK

- What is the function of laboratory autoclaves in SCWR research? Predict Material Compatibility and Corrosion Kinetics

- What role do laboratory autoclaves play in pectin extraction? Optimize Prebiotic Yield from Citrus and Apple Biomass