At its core, a controlled atmosphere (CA) room works by replacing the air inside with a precisely managed blend of gases. This new atmosphere, typically very low in oxygen and sometimes higher in carbon dioxide, dramatically slows the natural aging and decay processes in perishable products like fruits and vegetables, extending their life and preserving their quality far beyond the capabilities of simple refrigeration.

A controlled atmosphere room is not just a cold space; it is a sealed, high-tech hibernation chamber for produce. By actively managing the air composition—specifically oxygen, carbon dioxide, and ethylene—it puts the biological processes of ripening and decay on pause.

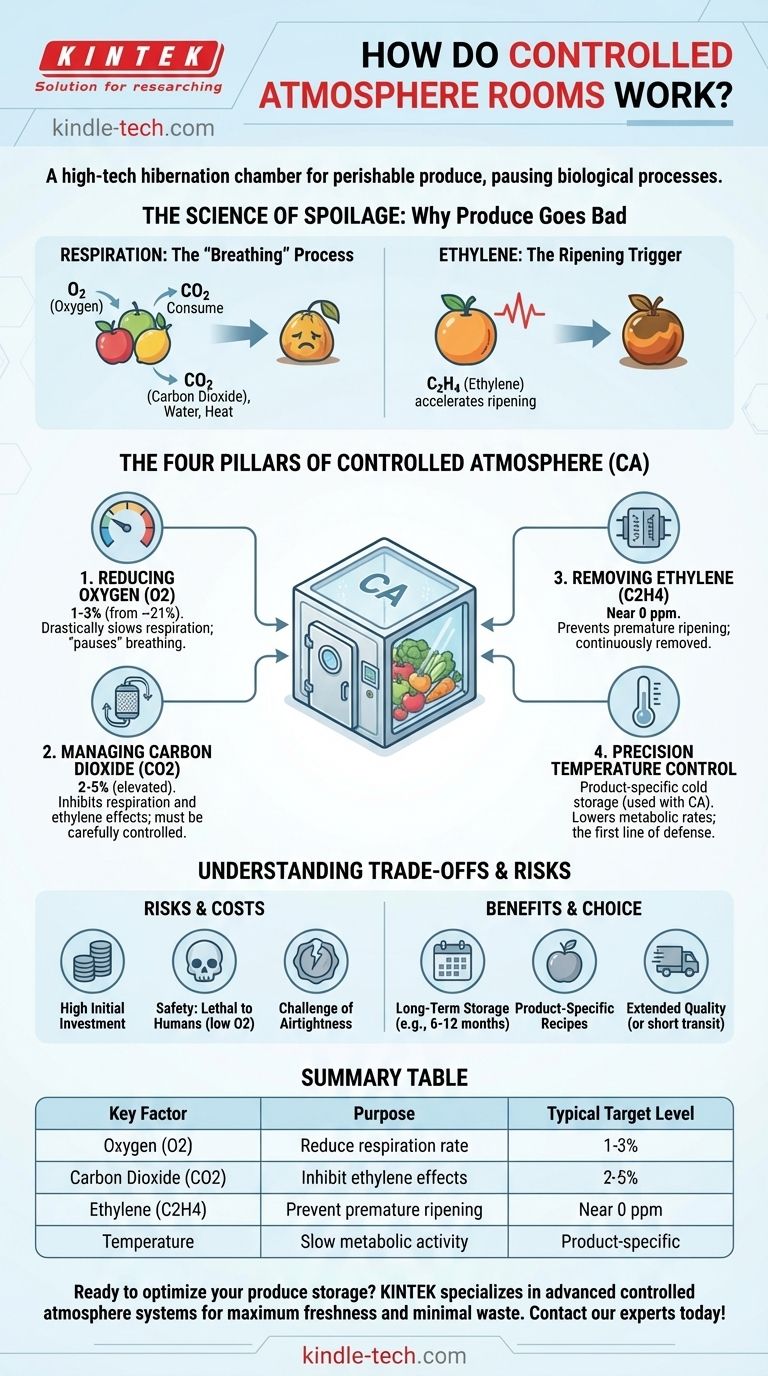

The Science of Spoilage: Why Produce Goes Bad

To understand how CA storage works, you must first understand why harvested produce naturally spoils. Even after being picked, fruits and vegetables are living organisms that continue to undergo biological processes.

Respiration: The "Breathing" Process

Just like animals, harvested produce "breathes" in a process called respiration. They consume oxygen (O2) from the air and use it to break down their stored sugars for energy.

This process releases carbon dioxide (CO2), water, and heat. Unchecked, this rapid respiration quickly consumes the product's reserves, leading to softening, weight loss, and eventual decay.

Ethylene: The Ripening Trigger

Many fruits produce ethylene, a natural plant hormone gas that acts as a powerful signaling molecule. Even in tiny concentrations, it triggers and accelerates the ripening process—softening texture, changing color, and developing flavor.

While necessary for fruit to become edible, uncontrolled ethylene production after harvest leads to over-ripening and rapid spoilage, and the gas from one piece of fruit can trigger the entire batch to ripen prematurely.

The Four Pillars of a Controlled Atmosphere

A CA system precisely manipulates the storage environment to counteract these natural processes. This is achieved by managing four critical variables.

Pillar 1: Reducing Oxygen (O2)

This is the primary lever of CA storage. By reducing ambient oxygen levels from the normal ~21% down to a very low 1-3%, the rate of respiration is drastically reduced.

With less oxygen available, the produce simply cannot "breathe" as fast. Nitrogen gas (N2), which is inert, is typically used to flush the room and displace the oxygen.

Pillar 2: Managing Carbon Dioxide (CO2)

While produce releases CO2 during respiration, intentionally elevating CO2 levels in the room to 2-5% (or higher for some products) can further inhibit respiration and suppress the effects of ethylene.

However, CO2 levels must be carefully controlled. Too much CO2 can damage the produce, causing internal browning, off-flavors, and other physiological disorders. Excess CO2 produced by the fruit must be actively removed or "scrubbed" from the air.

Pillar 3: Removing Ethylene (C2H4)

Because ethylene is such a potent ripening agent, it must be continuously removed from the atmosphere. Specialized ethylene scrubbers or converters use catalysts to actively break down ethylene molecules.

Keeping ethylene concentrations near zero is critical for long-term storage, preventing the entire stock from beginning the irreversible slide into senescence and decay.

Pillar 4: Precision Temperature Control

Controlled atmosphere is almost always used in conjunction with refrigeration. Temperature is a powerful factor in metabolic rates, and lowering it is the first line of defense.

CA technology builds upon the foundation of cold storage, with each system—refrigeration and atmosphere control—amplifying the effect of the other to achieve maximum preservation.

Understanding the Trade-offs and Risks

While incredibly effective, implementing a CA system is a significant undertaking with associated risks and costs that demand careful consideration.

High Initial Investment

Building a truly airtight room and installing the necessary equipment—nitrogen generators, CO2 and ethylene scrubbers, and sophisticated sensor and control systems—represents a major capital expense compared to a standard cold room.

The Danger of "One Size Fits All"

Different products require different atmospheric "recipes." The ideal O2, CO2, and temperature levels for a 'Honeycrisp' apple are different from those for a pear or a kiwi. Applying the wrong recipe can be worse than using no CA at all, leading to low-oxygen injury or high-CO2 damage.

Critical Safety Considerations

A low-oxygen atmosphere that preserves fruit is lethal to humans. CA rooms are extremely dangerous environments that require strict safety protocols, including comprehensive monitoring, alarm systems, and procedures for safe entry.

The Challenge of Airtightness

The entire system's effectiveness and efficiency hinge on the room being perfectly sealed. Any leaks force the system to work harder to maintain the desired atmosphere, increasing operational costs and potentially compromising the stored product.

Making the Right Choice for Your Operation

The decision to use controlled atmosphere technology depends entirely on your specific goals, product, and supply chain.

- If your primary focus is maximum shelf-life for long-term storage (e.g., holding apples for 6-12 months): A full-scale, dynamic CA system is the only technology that can achieve this, making the investment necessary to meet market demand year-round.

- If your primary focus is extending quality for a few weeks or during transit: A simpler or less permanent solution like modified atmosphere packaging (MAP) or temporary container-based systems may be a more cost-effective approach.

- If you are considering your first CA system: Prioritize your investment in the two most critical components: a flawlessly constructed, tested airtight room and expert consultation to determine the precise atmospheric recipes for your specific products.

By taking direct control of the post-harvest environment, you are no longer just fighting decay; you are actively managing the life and quality of your product.

Summary Table:

| Key Factor | Purpose | Typical Target Level |

|---|---|---|

| Oxygen (O2) | Reduce respiration rate | 1-3% |

| Carbon Dioxide (CO2) | Inhibit ethylene effects | 2-5% |

| Ethylene (C2H4) | Prevent premature ripening | Near 0 ppm |

| Temperature | Slow metabolic activity | Product-specific |

Ready to optimize your produce storage and extend shelf life? KINTEK specializes in advanced laboratory and storage solutions, including controlled atmosphere systems. Our expertise ensures precise environmental control for your specific products, from apples to leafy greens. Let us help you design a system that maximizes freshness and minimizes waste. Contact our experts today to discuss your needs!

Visual Guide

Related Products

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

- Controlled Nitrogen Inert Hydrogen Atmosphere Furnace

People Also Ask

- Why must the carbonization process for carbon nanofibers be performed in an atmosphere tube furnace? Expert Insights

- How does a tube atmosphere furnace provide the necessary sintering environment for converting lignin foam? Expert Guide

- How do vacuum or atmosphere furnaces enable near-net-shape forming during the reaction sintering of Silicon Carbide?

- What are the safety precautions for argon welding? Essential Guide to Protecting Against UV, Fumes, Shock, and Asphyxiation

- What is the purpose of using an atmosphere-controlled heating furnace for Cu reduction? Achieve Active Catalytic States

- Why is a protective argon atmosphere utilized for porous Nitinol synthesis? Ensure Purity and Biocompatibility

- What is the role of high-temperature atmosphere control furnaces in the sintering process of 316L stainless steel?

- What are the important applications of inert gases? Essential Uses from Welding to Food Preservation