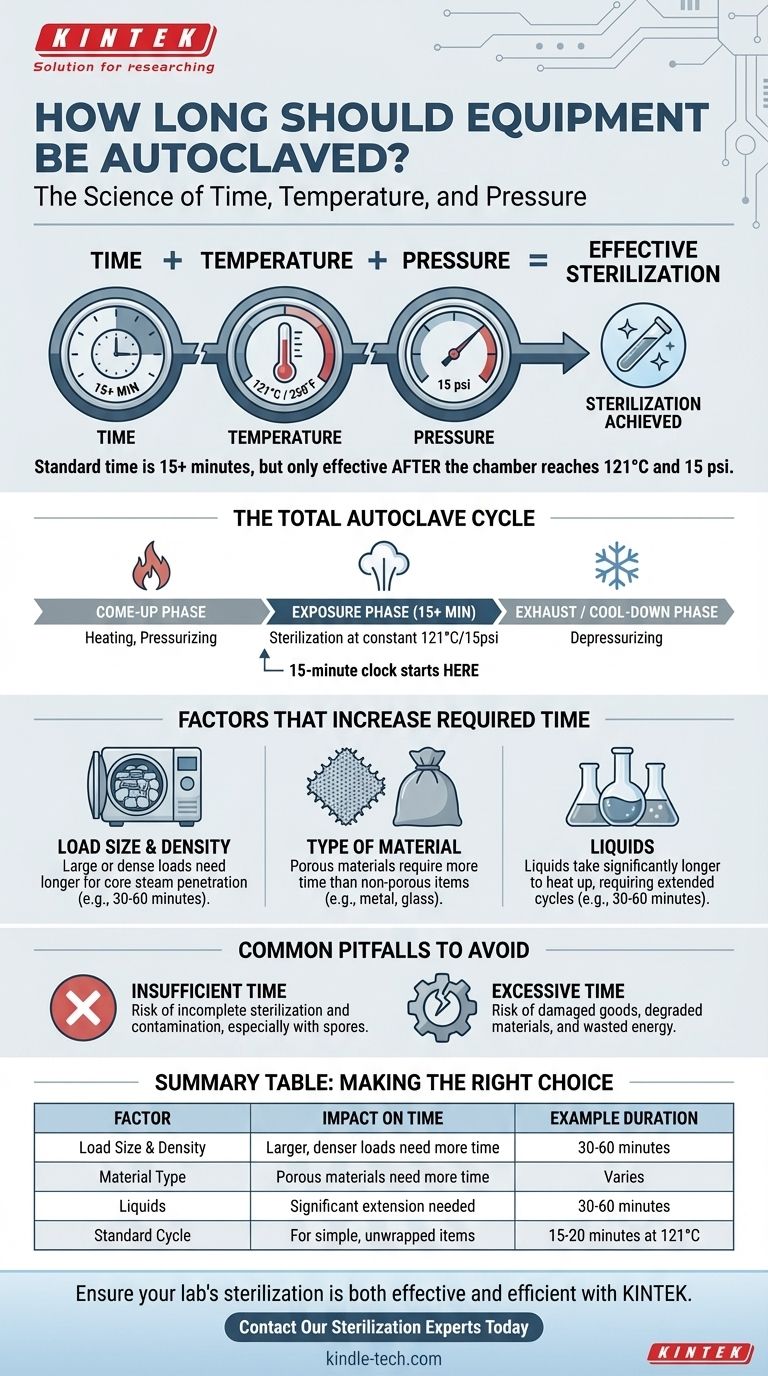

The standard autoclave sterilization time is a minimum of 15 minutes. However, this time requirement is only effective when the autoclave chamber has reached the correct temperature of 121°C (250°F) and a pressure of 15 psi. Simply setting a 15-minute timer is not enough to guarantee sterilization.

Sterilization in an autoclave is not just about time; it's a function of time, temperature, and pressure working together. The 15-minute standard is only valid if the correct temperature and pressure have been reached and are consistently maintained for the entire duration of the exposure phase.

The Principles of Steam Sterilization

To use an autoclave correctly, it's essential to understand that the timer is only one part of a larger process. The real work is done by high-pressure saturated steam, which effectively transfers heat to kill all microbial life, including resilient bacterial spores.

Why Time Alone Isn't Enough

The "sterilization time" or "exposure time" refers only to the period when the contents are held at the sterilizing temperature.

The total cycle is longer and includes a "come-up" phase for the chamber to heat up and pressurize, and an "exhaust" or "cool-down" phase. The 15-minute clock should only begin after the come-up phase is complete.

The 121°C / 15 psi Standard

The combination of 121°C and 15 psi is the industry benchmark for steam sterilization. At this pressure, water becomes superheated steam, which can penetrate materials and rapidly denature the essential proteins within microorganisms.

This specific temperature is proven effective at destroying even the most heat-resistant bacterial endospores, which are the primary benchmark for a successful sterilization cycle.

Factors That Change the Required Time

While 15 minutes is the baseline, it is only appropriate for simple, non-porous items. You must adjust the time based on the contents of the autoclave to ensure the steam fully penetrates the entire load.

Load Size and Density

A large or densely packed load will take longer for steam to penetrate to its core. A small load of loose glass beakers requires less time than a large, tightly packed bag of waste.

For dense loads, the exposure time may need to be increased to 30 minutes or more to ensure the items in the very center reach 121°C and are held there for the minimum duration.

Type of Material

The nature of the items being sterilized is a critical factor.

Hard, non-porous surfaces like metal instruments or glassware sterilize relatively quickly. Porous materials like textiles or items inside filter-patch bags require longer cycles for the steam to displace air and make contact with every surface.

Liquids

Sterilizing liquids, such as media in flasks, requires a significantly longer cycle time. This is because a large volume of liquid takes much longer to heat up to the target temperature than a solid object does.

Common Pitfalls to Avoid

Understanding the potential for failure is just as important as knowing the standard procedure. Misjudging the cycle parameters can lead to wasted time, damaged goods, or incomplete sterilization.

The Risk of Insufficient Time

The most obvious danger is incomplete sterilization. If the exposure time is too short for the load type, microorganisms—especially spores—can survive. This can lead to contamination, failed experiments, and significant safety risks.

The Risk of Excessive Time

Running a cycle for too long can also be detrimental. Over-sterilizing can degrade certain plastics, dull the sharp edges of instruments, and potentially break down the chemical components in laboratory media. It is also an unnecessary use of energy and time.

Making the Right Choice for Your Goal

Always refer to your specific autoclave's manual and your institution's protocols. However, you can use these general principles to guide your decisions.

- If your primary focus is sterilizing standard laboratory glassware or unwrapped metal instruments: A 15-20 minute cycle at 121°C is the reliable industry standard once the chamber reaches temperature.

- If your primary focus is sterilizing liquids, dense packs, or large biohazard bags: Increase the exposure time to 30-60 minutes to ensure the core of the load reaches the target temperature.

- If your primary focus is sterilizing heat-sensitive items: Consult the manufacturer's guidelines, as you may need a different temperature/time combination (e.g., 134°C for a shorter time) or an entirely different sterilization method.

Ultimately, effective autoclaving relies on understanding that time is a tool to ensure complete steam penetration and is not a one-size-fits-all setting.

Summary Table:

| Factor | Impact on Sterilization Time |

|---|---|

| Load Size & Density | Larger, denser loads require longer times (e.g., 30-60 minutes) for steam penetration. |

| Material Type | Porous materials (textiles, bags) need more time than non-porous items (glass, metal). |

| Liquids | Significant extension needed due to slow heating (e.g., 30-60 minutes). |

| Standard Cycle | 15-20 minutes at 121°C for simple, unwrapped items after chamber reaches temperature. |

Ensure your lab's sterilization is both effective and efficient with the right equipment from KINTEK.

Whether you're processing standard glassware, dense biohazard waste, or sensitive liquids, our autoclaves are designed to deliver reliable performance and precise control.

Contact our sterilization experts today to find the perfect autoclave solution for your laboratory's specific needs.

Visual Guide

Related Products

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- What extreme conditions does a laboratory autoclave simulate? Testing Wear Resistance of Nuclear Fuel Cladding

- What is the use of autoclave in research? Ensure Sterile Conditions for Valid Scientific Results

- What is the protocol for sterilization of glassware? A Step-by-Step Guide to Lab-Ready Sterility

- Why is 121 degrees used in autoclave? The Science Behind Reliable Sterilization

- How are autoclaves used to sterilize surgical instruments? Master the Key Steps for Patient Safety

- Why must Ni-Cr alloy and carbon-coated samples be treated in a pressure steam autoclave? Ensure Data Integrity

- What are the common uses of autoclave? Achieve Absolute Sterility for Safety and Precision

- How does an autoclave work in microbiology? Achieve Complete Sterilization with High-Pressure Steam