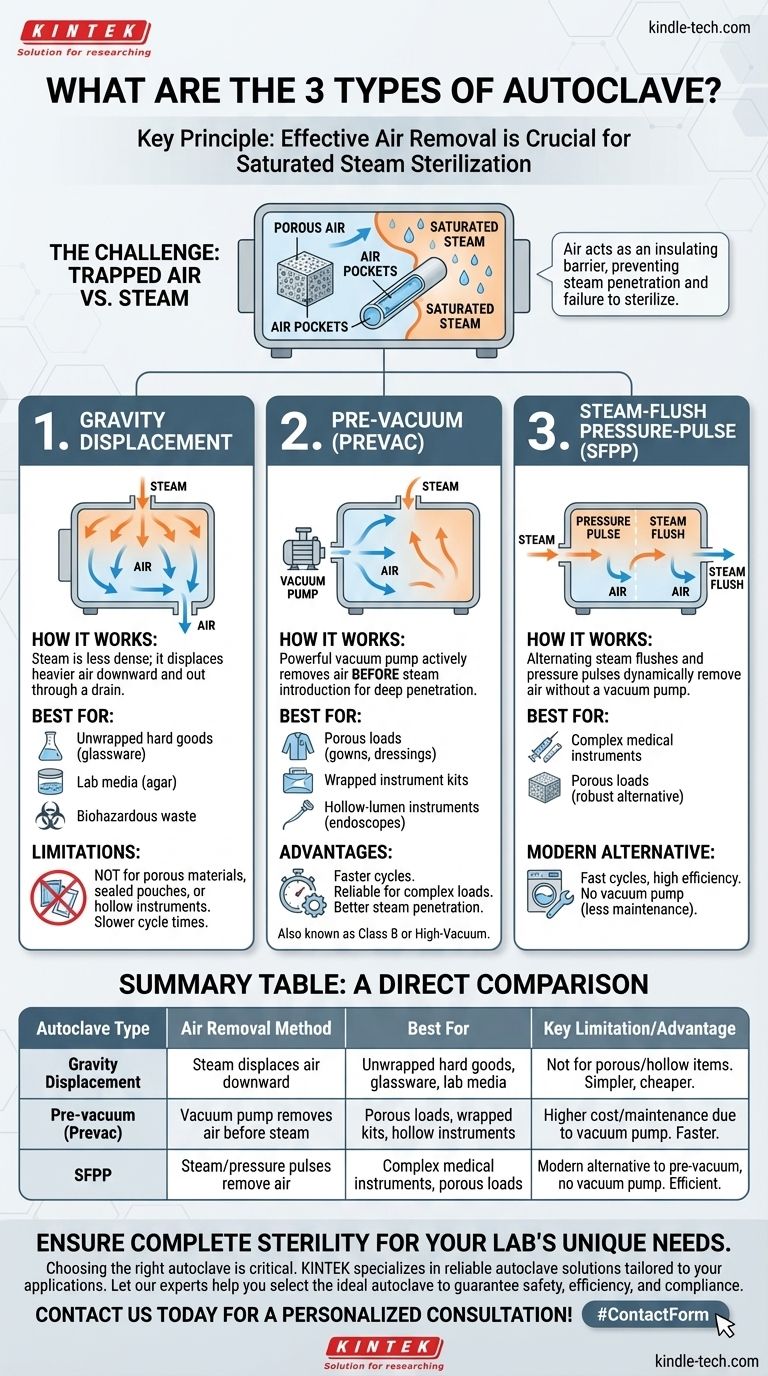

The three primary types of autoclaves are defined by the method they use to remove air from the sterilization chamber: Gravity Displacement, Pre-vacuum (Prevac), and Steam-Flush Pressure-Pulse (SFPP). The efficiency of air removal is the single most important factor determining an autoclave's ability to sterilize different types of loads, from simple glassware to complex surgical instruments.

The core challenge in steam sterilization is not just reaching a high temperature, but ensuring that saturated steam makes direct contact with every surface. The choice between autoclave types comes down to one critical question: how effectively can it remove trapped air from your specific load?

The Fundamental Principle: Why Air Removal is Critical

To understand the difference between autoclave types, you must first understand why removing ambient air is non-negotiable for effective sterilization.

The Role of Saturated Steam

Sterilization in an autoclave is achieved not by dry heat, but by the condensation of saturated steam. When steam condenses on a cooler object, it releases a massive amount of latent heat energy, which rapidly denatures the proteins in microorganisms, killing them.

The Problem with Trapped Air

Air acts as an insulating barrier, preventing steam from making direct contact with the items being sterilized. An air pocket trapped inside a piece of tubing or a fabric bundle will not reach the required sterilization temperature, creating a critical point of failure.

Type 1: Gravity Displacement Autoclaves

This is the most fundamental and common type of autoclave, relying on a simple physical principle.

How It Works

As steam is fed into the chamber, it fills the upper areas first because it is less dense than the cooler, heavier air. This incoming steam displaces the air, pushing it downward and out through a drain vent. The cycle only begins its sterilization timer once the sensor reaches the target temperature.

Common Applications

Gravity autoclaves are best suited for sterilizing unwrapped hard goods, glassware, and lab media (like agar). They are also used for sterilizing biohazardous waste.

Key Limitations

These units are not effective for sterilizing porous materials (like fabrics or gowns), items in sealed pouches, or hollow instruments like tubing. Air can easily become trapped in these loads, preventing proper sterilization. Cycle times are also generally longer.

Type 2: Pre-vacuum (Prevac) Autoclaves

Pre-vacuum systems, also known as high-vacuum or Class B autoclaves, take an active approach to air removal.

How It Works

Before introducing any steam, a powerful vacuum pump actively removes the air from the chamber and the load. This is often done in a series of vacuum and pressure pulses to ensure maximum air removal from even the most complex items. Only then is steam introduced into the near-vacuum, allowing for instantaneous and deep penetration.

Common Applications

Prevac systems are the standard in medical and dental settings. They are required for sterilizing porous loads (gowns, dressings), wrapped instrument kits, and hollow-lumen instruments (like endoscopes and dental handpieces).

Key Advantages

This method provides faster cycle times, more reliable sterilization of complex loads, and better steam penetration than gravity displacement.

Type 3: Steam-Flush Pressure-Pulse (SFPP) Autoclaves

SFPP is a more modern design that achieves the same goal as a pre-vacuum system but with a different mechanism.

How It Works

Instead of using a vacuum pump, this process uses a series of steam flushes and pressure pulses. The chamber is alternately pressurized with steam and then vented to atmospheric pressure. Each pulse dynamically removes air, achieving a level of air removal comparable to pre-vacuum systems.

Common Applications

These are used for the same applications as pre-vacuum autoclaves, serving as a robust alternative for sterilizing complex medical instruments and porous loads.

A Modern Alternative

SFPP systems can achieve faster cycles and are sometimes considered more reliable because they do not depend on a vacuum pump, which can be a point of mechanical failure and require regular maintenance.

Understanding the Trade-offs: A Direct Comparison

Choosing the right technology involves balancing capability, speed, and cost.

Sterilization Speed

Pre-vacuum and SFPP autoclaves are significantly faster than gravity models. By actively removing air, they reduce the overall cycle time needed to heat and penetrate the load.

Load Complexity

This is the most critical distinction. A gravity autoclave is only suitable for simple, non-porous loads. For porous or hollow items, a Prevac or SFPP system is mandatory to guarantee sterility.

Cost and Maintenance

Gravity displacement units are simpler mechanically, making them less expensive to purchase and maintain. Pre-vacuum systems require a vacuum pump, adding to the initial cost and introducing a component that needs regular service. SFPP systems can be a middle ground, offering high performance without a vacuum pump.

Making the Right Choice for Your Application

Your decision should be dictated entirely by the type of materials you need to sterilize.

- If your primary focus is sterilizing simple lab media, glassware, or unwrapped solid instruments: A Gravity Displacement autoclave is a cost-effective and reliable choice.

- If your primary focus is sterilizing complex loads like surgical kits, fabrics, or tubing: A Pre-vacuum (often called a Class B) autoclave is essential for ensuring complete air removal and sterility.

- If your primary focus is rapid processing in a high-throughput hospital or clinical environment: A Steam-Flush Pressure-Pulse (SFPP) system offers a modern, highly efficient alternative to traditional pre-vacuum cycles.

Understanding the mechanism of air removal is the key to selecting the autoclave that guarantees sterility for your specific needs.

Summary Table:

| Autoclave Type | Air Removal Method | Best For | Key Limitation |

|---|---|---|---|

| Gravity Displacement | Steam displaces air downward | Unwrapped hard goods, glassware, lab media | Not suitable for porous or hollow items |

| Pre-vacuum (Prevac) | Vacuum pump removes air before steam | Porous loads, wrapped kits, hollow instruments | Higher cost and maintenance due to vacuum pump |

| Steam-Flush Pressure-Pulse (SFPP) | Steam/pressure pulses remove air | Complex medical instruments, porous loads | Modern alternative to pre-vacuum, no vacuum pump |

Ensure complete sterility for your lab's unique needs. Choosing the right autoclave is critical for effective sterilization, whether you're processing simple glassware or complex surgical kits. KINTEK specializes in lab equipment and consumables, serving laboratory needs with reliable autoclave solutions tailored to your applications. Let our experts help you select the ideal autoclave to guarantee safety, efficiency, and compliance. Contact us today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

People Also Ask

- Why is a high-pressure autoclave essential for HMF conversion? Achieve Efficient Lignocellulose Synthesis

- How long does an autoclave cycle take? Understanding the 25-60 Minute Sterilization Process

- Why is autoclave temperature 134? Achieve Rapid Sterilization for Critical Instruments

- Why are silver or platinum liners utilized in GaN synthesis? Protecting Purity and Autoclave Integrity

- How does an autoclave contribute to the reliability of results in biofilm formation experiments? Ensure Data Integrity

- What are the considerations for autoclave? Ensure Sterilization Success and Safety

- What can you use instead of autoclave? Find the Right Sterilization Method for Your Materials

- How do high-pressure autoclave systems simulate nuclear reactor environments? Precision sCO2 Corrosion Studies