At its core, centrifugal extraction offers a powerful combination of speed, efficiency, and a remarkably compact footprint. It uses immense rotational force to achieve in seconds what traditional gravity-based methods might take hours to accomplish, making it a cornerstone of modern high-throughput chemical, pharmaceutical, and biological processing.

While conventional separation relies on the slow, passive force of gravity, centrifugal extraction actively drives the process by multiplying that force thousands of times. This fundamental shift makes it the definitive solution for processes demanding high speed, exceptional purity, and the ability to handle otherwise difficult-to-separate mixtures.

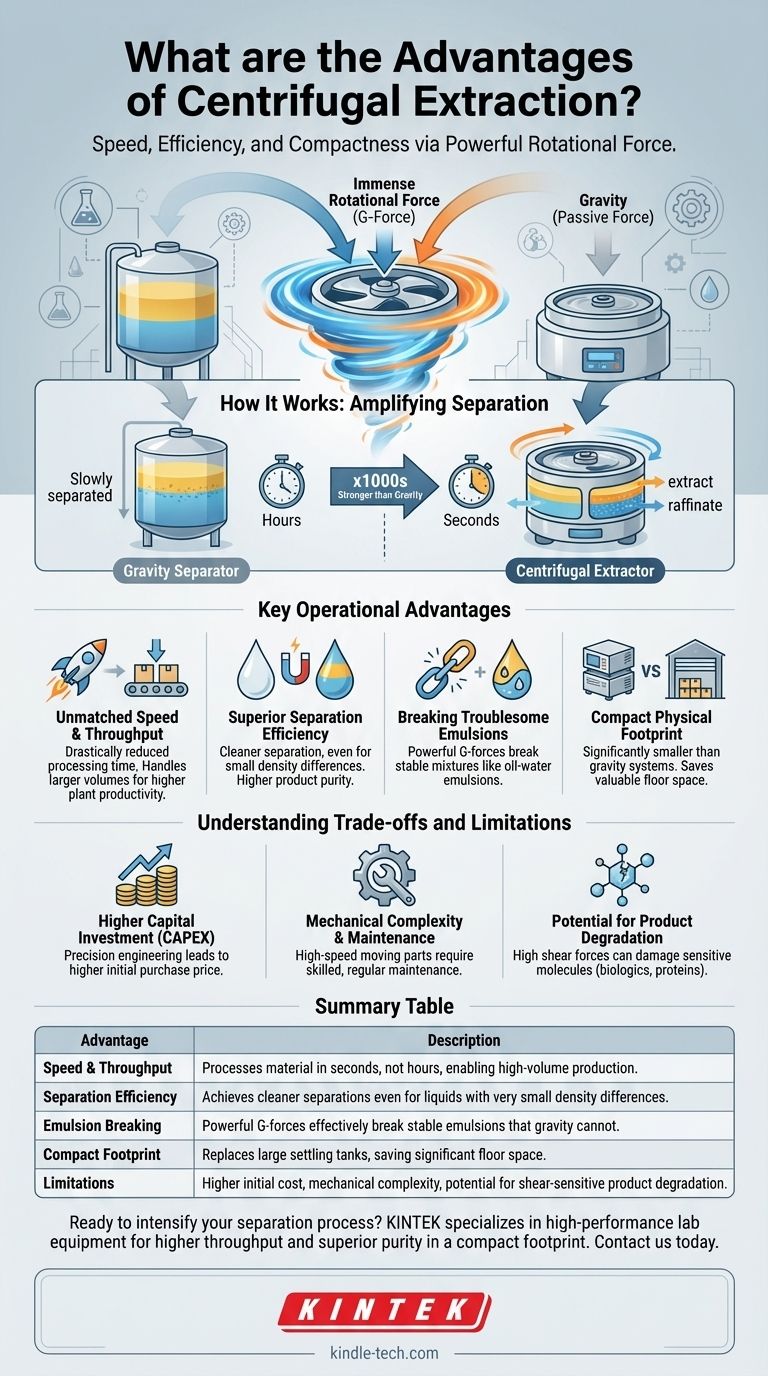

How Centrifugal Extraction Works: Amplifying Separation

To understand the advantages of centrifugal extraction, you must first grasp its fundamental principle: it replaces the gentle pull of gravity with powerful centrifugal force.

The Core Principle: G-Force vs. Gravity

A standard gravity separator, like a large settling tank or a separatory funnel in a lab, relies on the natural density difference between two immiscible liquids. The denser liquid slowly settles to the bottom over time.

A centrifugal extractor spins a mixture at high speeds, creating a gravitational field (G-force) that can be thousands of times stronger than Earth's. This immense force dramatically accelerates the separation of the denser and lighter phases.

Maximizing Contact, Minimizing Time

Inside the extractor, the two liquid phases are first intensely mixed, creating a massive interfacial area for the desired solute to transfer from one liquid to the other.

Immediately after this contact, the high G-force separates the newly formed liquids—the extract and the raffinate—almost instantaneously. This entire process of mixing and separating occurs in a very short "residence time."

Key Operational Advantages Explained

The underlying mechanism of high G-force translates directly into significant, measurable benefits for industrial and lab-scale processes.

Unmatched Speed and Throughput

The most significant advantage is speed. By drastically reducing the time required for phase separation, centrifugal extractors can process a much larger volume of material in a given period compared to gravity settlers of a similar capacity. This leads to higher plant throughput and productivity.

Superior Separation Efficiency

The powerful forces can separate liquids with very small density differences, a task that is often slow, inefficient, or impossible with gravity alone. This results in a cleaner separation, higher product purity, and reduced loss of valuable material in the waste stream.

Breaking Troublesome Emulsions

Emulsions are stable mixtures of liquids that do not separate easily under gravity. The high shear forces and G-forces inside a centrifugal extractor are powerful enough to break these emulsions, making it the go-to technology for applications like oil-water separation or certain pharmaceutical extractions.

Compact Physical Footprint

Because the separation process is so intense and fast, the equipment is significantly smaller than a gravity-based system designed for the same throughput. A centrifugal extractor can replace a settling tank that is orders of magnitude larger, saving valuable floor space in a plant or lab.

Understanding the Trade-offs and Limitations

No technology is a universal solution. An objective evaluation requires acknowledging the potential downsides of centrifugal extraction.

Higher Capital Investment (CAPEX)

Centrifugal extractors are precision-engineered machines with high-speed moving parts. This makes their initial purchase price significantly higher than that of a simple tank or mixer-settler system.

Mechanical Complexity and Maintenance

The high-speed rotor, bearings, and seals are subject to wear and require regular, skilled maintenance. This contributes to higher operational costs (OPEX) and potential downtime if not managed properly.

Potential for Product Degradation

The same high shear forces that are excellent for mixing can sometimes damage sensitive molecules. For delicate biologics, proteins, or certain organic compounds, the shear stress must be carefully evaluated to prevent product degradation.

Making the Right Choice for Your Process

Your decision to use centrifugal extraction should be driven by the specific demands of your process and your primary business goals.

- If your primary focus is high-volume production and throughput: Centrifugal extraction is the superior choice due to its rapid processing time.

- If your primary focus is separating stable emulsions or liquids with low density differences: This technology is often the only viable method to achieve a clean and efficient separation.

- If your primary focus is minimizing initial capital costs: A traditional gravity-based mixer-settler system will be a more economical starting point, provided you can tolerate slower processing times.

- If your primary focus is processing highly shear-sensitive products: You must carefully test and select a centrifugal extractor designed for gentle handling, or consider alternative low-shear methods.

Ultimately, choosing this technology is an investment in process intensification—a way to achieve more output, with higher purity, in less space.

Summary Table:

| Advantage | Description |

|---|---|

| Speed & Throughput | Processes material in seconds, not hours, enabling high-volume production. |

| Separation Efficiency | Achieves cleaner separations even for liquids with very small density differences. |

| Emulsion Breaking | Powerful G-forces effectively break stable emulsions that gravity cannot. |

| Compact Footprint | Replaces large settling tanks, saving significant floor space. |

| Limitations | Higher initial cost, mechanical complexity, and potential for shear-sensitive product degradation. |

Ready to intensify your separation process? KINTEK specializes in high-performance lab equipment, including centrifugal extraction systems designed for chemical, pharmaceutical, and biological applications. Our experts can help you achieve higher throughput and superior purity in a compact footprint. Contact us today to discuss how our solutions can meet your specific laboratory needs.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Benchtop Laboratory Vacuum Freeze Dryer

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Benchtop Laboratory Freeze Dryer for Lab Use

People Also Ask

- What is a lab autoclave? Your Guide to Sterilization with Pressurized Steam

- Why is it important to autoclave the prepared reagents before using? Ensure Sterility and Reliable Results

- Do you need to autoclave glassware? A Guide to Sterilization vs. Cleaning

- How do you sterilize glassware by autoclave? Master the 3-Step Process for Reliable Sterility

- What are the advantages of autoclaving in hospitals? Achieve Unmatched Sterilization for Patient Safety