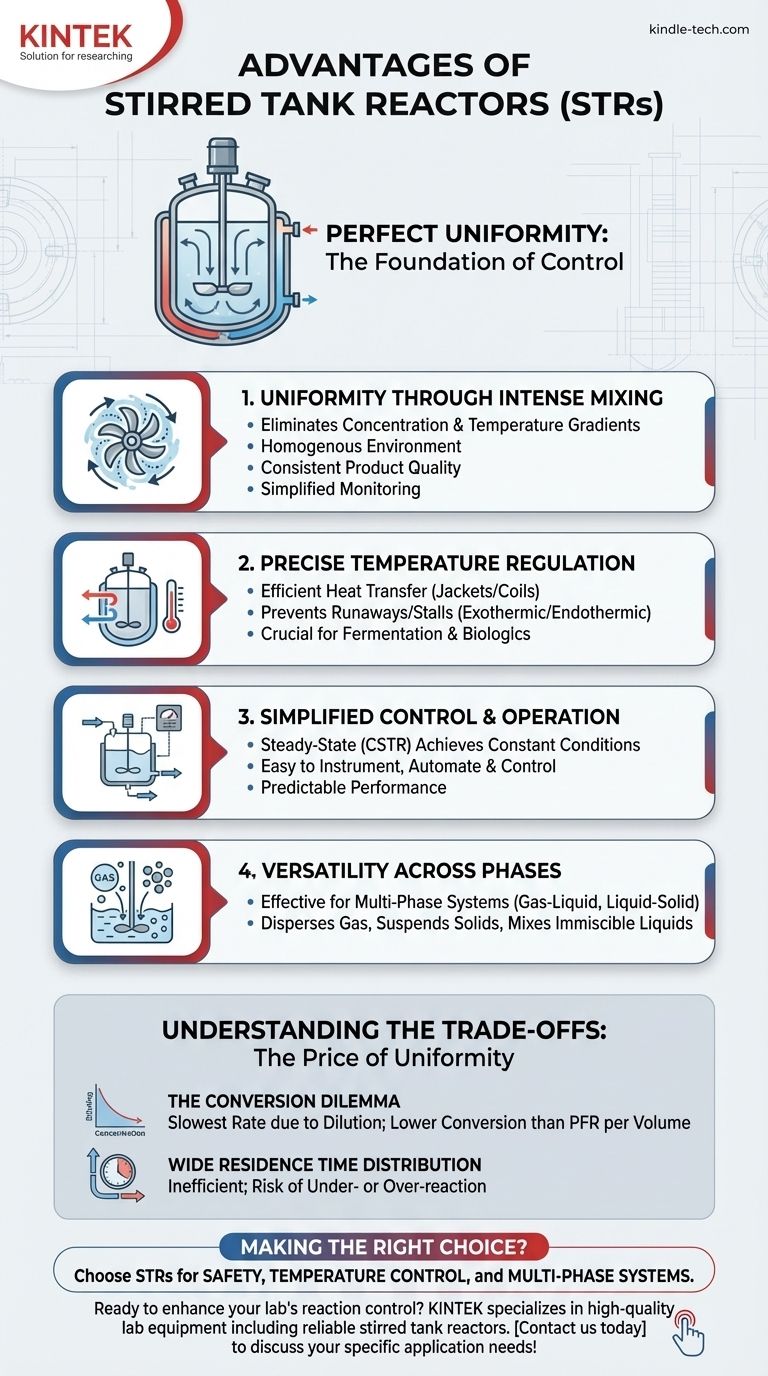

At their core, stirred tank reactors (STRs) offer unparalleled control over the reaction environment. Their primary advantages stem from their ability to create a perfectly uniform mixture, ensuring consistent temperature, pH, and reactant concentration throughout the entire vessel. This makes them exceptionally versatile and reliable for a wide range of chemical and biological processes where precise control is paramount.

The fundamental advantage of a stirred tank reactor is its promotion of uniformity. This homogeneity is its greatest strength, enabling precise process control, but it also creates inherent trade-offs, particularly regarding reaction efficiency, that you must understand to make the right choice.

The Foundation: How Stirred Tanks Achieve Control

The design of a stirred tank reactor is deceptively simple, but this simplicity is what allows for such robust control over complex processes.

Uniformity Through Intense Mixing

An impeller, driven by a motor, creates high levels of turbulence within the vessel. This intense mixing virtually eliminates any concentration or temperature gradients.

The result is a perfectly homogenous environment. A sample taken from any point in the reactor is representative of the entire batch, which dramatically simplifies monitoring and analysis.

Precise Temperature Regulation

Most STRs are equipped with an external heating or cooling jacket, or internal coils. The constant, rapid fluid movement ensures that heat is transferred efficiently and evenly to or from the entire reaction mass.

This capability is critical for exothermic reactions (which release heat) or endothermic reactions (which absorb heat), preventing dangerous temperature runaways or process stalls. It is also essential for biological processes like fermentation, which require a very narrow temperature range for optimal cell viability.

Simplified Control and Operation

When operated continuously (as a CSTR, or Continuous Stirred-Tank Reactor), the system reaches a steady-state. This means that product is withdrawn at the same rate that reactants are fed, and the conditions inside the reactor (temperature, concentration) remain constant over time.

This steady-state operation is straightforward to instrument, automate, and control, leading to consistent product quality and predictable performance.

Versatility Across Phases

The powerful agitation makes STRs ideal for handling multi-phase systems. They can effectively disperse gas bubbles in a liquid (gas-liquid reactions like hydrogenation), suspend solid particles in a fluid (liquid-solid slurries or crystallizations), or mix immiscible liquids.

Understanding the Trade-offs: The Price of Uniformity

The perfect mixing that defines the STR also introduces its most significant limitations. Understanding these is key to avoiding misapplication.

The Conversion Dilemma

Because the reactor is perfectly mixed, the concentration of reactants inside the vessel is instantly diluted to the same low concentration as the material exiting the reactor.

Since reaction rate is typically dependent on reactant concentration, the reaction proceeds at its slowest possible rate throughout the entire reactor volume. In contrast, a Plug Flow Reactor (PFR) maintains a high concentration at the inlet, leading to a much higher initial reaction rate and generally higher conversion for the same reactor volume.

Wide Residence Time Distribution

Perfect mixing means some fluid elements will pass through the reactor very quickly, while others will remain for a very long time. This wide distribution can be inefficient.

The short-circuiting fluid leaves before it has a chance to fully react, lowering overall conversion. The fluid that remains too long may risk over-reaction or product degradation.

Scale-Up Challenges

While an STR is versatile, scaling from a lab-bench reactor to a large industrial vessel is not a trivial task.

Maintaining the same level of mixing and heat transfer per unit volume becomes progressively harder. Engineers must carefully consider factors like impeller power per volume, tip speed, and heat transfer surface area to ensure the large-scale reactor performs as expected.

Making the Right Choice for Your Process

Choosing a reactor is about aligning the reactor's characteristics with your primary process goal. An STR is not always the best choice, but it is often the safest and most controllable.

- If your primary focus is maximizing reaction conversion per unit volume: An STR is often less efficient than a PFR; consider a PFR or using multiple, smaller STRs in series to better approximate plug flow behavior.

- If your primary focus is precise temperature control for a sensitive or highly exothermic reaction: The STR is almost always the superior and safer choice due to its ability to eliminate hot spots.

- If your primary focus is processing multiple phases (gas-liquid, liquid-solid) or slurries: The STR's agitation makes it uniquely suited for maintaining the homogeneity required for these complex systems.

- If your primary focus is producing biologics like enzymes or cells: The STR (or bioreactor) provides the gentle mixing and tight environmental control (pH, temperature, dissolved oxygen) essential for cell culture and fermentation.

Ultimately, the stirred tank reactor remains the workhorse of the process industries because it provides a robust and controllable environment for reactions that demand stability above all else.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Perfect Uniformity | Eliminates concentration/temperature gradients | Consistent product quality, simplified monitoring |

| Precise Temperature Control | Efficient heat transfer via jackets/coils | Exothermic/endothermic reactions, fermentation |

| Steady-State Operation (CSTR) | Constant conditions for predictable performance | Automated, continuous processes |

| Multi-Phase Versatility | Effective gas, liquid, and solid dispersion | Hydrogenation, crystallization, slurries |

Ready to enhance your lab's reaction control and efficiency? KINTEK specializes in high-quality lab equipment and consumables, including reliable stirred tank reactors designed for precise chemical and biological processes. Our solutions ensure the uniformity and control your laboratory demands. Contact us today to discuss how we can support your specific application needs!

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- How does a high-pressure reactor demonstrate its value in accelerated aging? Predict Catalyst Durability Fast

- What is the purpose of using high-purity argon gas in a high-pressure reactor? Ensure Precise Corrosion Test Data

- What is the function of a constant temperature hydrothermal reactor? Master Coal Fly Ash Activation

- Why are sealed laboratory reaction vessels necessary in the hydrothermal synthesis of zeolites? Ensure Purity and Yield

- What is the contribution of a hydrothermal reactor to graded pore construction? Precision Templates for TAS