Designing a successful bioreactor is about creating a perfectly controlled and sterile environment for living cells to thrive. Key design considerations revolve around providing uniform access to nutrients and oxygen (mass transfer), removing waste products and heat (heat transfer), maintaining a homogenous environment through mixing, and monitoring the process with precision, all while preventing any microbial contamination.

The goal of bioreactor design is not merely to build a container, but to engineer a precisely controlled, homogenous environment. Every design choice—from impeller shape to sensor placement—must serve the core purpose of meeting the specific metabolic demands of the living cells within, ensuring their optimal growth and productivity.

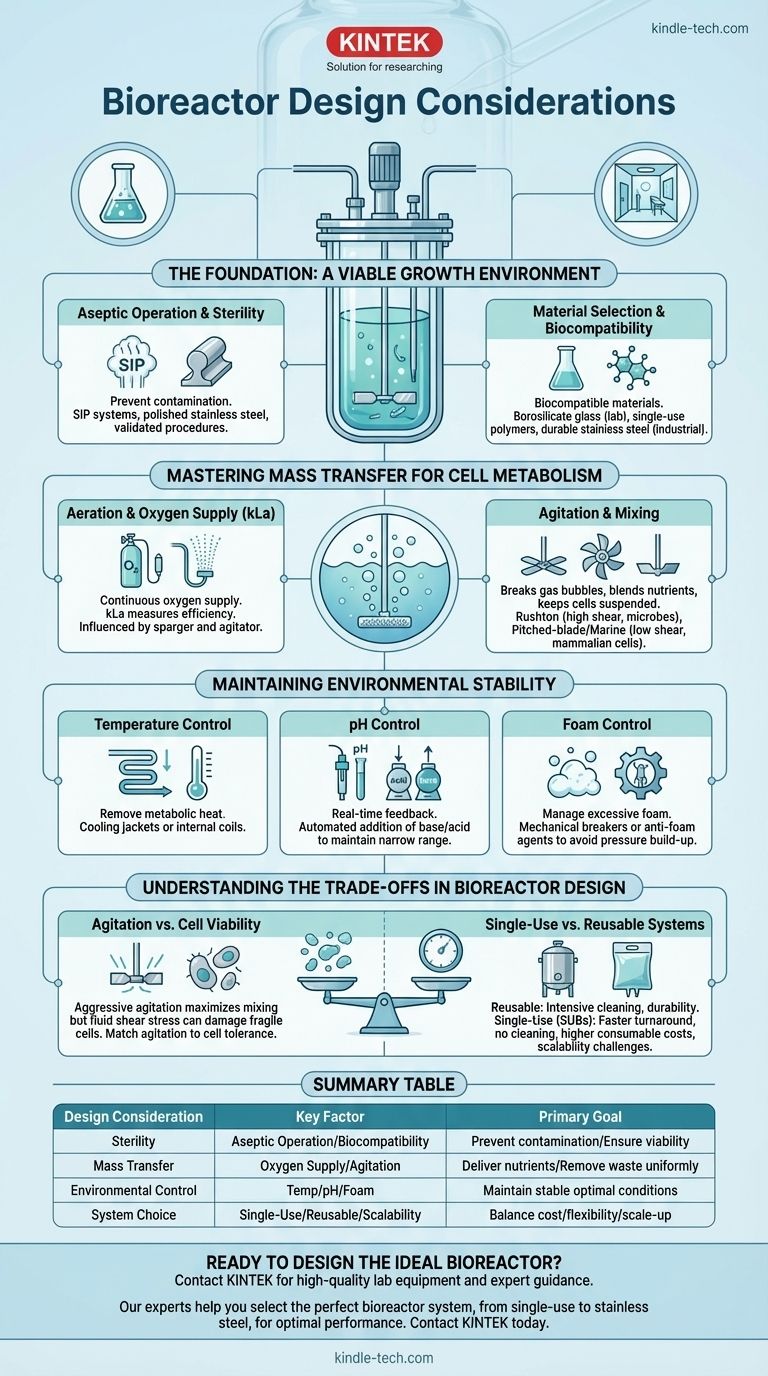

The Foundation: A Viable Growth Environment

Before any biological process can begin, the reactor itself must be a safe and sterile vessel. This is the non-negotiable starting point for all design.

Aseptic Operation and Sterility

Contamination by foreign microbes is the fastest way to ruin a bioprocess, as they compete for nutrients and can produce toxic metabolites. The design must ensure asepsis.

This is achieved through materials like polished 316L stainless steel or single-use plastics and validated sterilization procedures, such as Sterilize-in-Place (SIP) systems using high-pressure steam.

Material Selection and Biocompatibility

The materials that contact the cell culture must be biocompatible, meaning they do not leach toxic substances or inhibit cell growth.

For laboratory and pilot scales, borosilicate glass and single-use polymers are common. For industrial production, stainless steel is the standard due to its durability, heat transfer properties, and cleanability.

Mastering Mass Transfer for Cell Metabolism

A cell is a microscopic factory that consumes raw materials (nutrients, oxygen) and produces products. Mass transfer is the engineering discipline of efficiently delivering those raw materials to every single cell.

Aeration and Oxygen Supply (kLa)

Most commercially valuable cell cultures are aerobic, meaning they require oxygen to live. Since oxygen is poorly soluble in water, it must be continuously supplied.

The efficiency of oxygen delivery is measured by the volumetric mass transfer coefficient (kLa). A higher kLa means better oxygen transfer. This is influenced by the sparger, which releases gas into the media, and the agitator, which breaks down large bubbles to increase surface area for gas exchange.

Agitation and Mixing

Agitation serves three critical functions: it breaks up gas bubbles to improve aeration, it blends nutrients and pH-adjusting agents to create a homogenous environment, and it keeps cells suspended.

The choice of impeller is crucial. Rushton turbines create high shear, excellent for dispersing gas in robust microbial cultures. Pitched-blade or marine impellers create better axial flow with lower shear, making them ideal for fragile mammalian cells.

Maintaining Environmental Stability

Cells are sensitive to their surroundings. Small deviations in temperature or pH can drastically reduce growth rates and productivity.

Temperature Control

Cellular metabolism generates significant heat. If not removed, rising temperatures will kill the cells. Bioreactors use cooling jackets or internal coils through which a cooling fluid circulates to maintain the optimal temperature.

pH Control

As cells metabolize, they often produce acidic byproducts (e.g., lactic acid) that lower the pH of the culture medium. A pH sensor provides real-time feedback to a controller, which automatically pumps in a base (or acid) to keep the pH within a narrow, pre-defined range.

Foam Control

Sparring air or gas through protein-rich media creates foam. Excessive foam can block exhaust filters, leading to pressure build-up and loss of sterility. This is managed by mechanical foam breakers or the automated addition of chemical anti-foam agents.

Understanding the Trade-offs in Bioreactor Design

Designing a bioreactor is an exercise in balancing competing requirements. Understanding these trade-offs is the mark of an experienced engineer.

Agitation vs. Cell Viability

This is the classic dilemma. Aggressive agitation (high RPM, Rushton impeller) maximizes kLa and mixing, which is great for oxygen-hungry microbes. However, the associated fluid shear stress can damage or kill fragile mammalian, insect, or fungal cells. The design must match the agitation system to the cell's physical tolerance.

Single-Use vs. Reusable Systems

Traditional bioreactors are reusable stainless-steel tanks requiring intensive cleaning and sterilization between batches. Single-use bioreactors (SUBs), which use a pre-sterilized disposable bag, eliminate this cleaning overhead.

SUBs offer faster turnaround and lower capital investment but come with higher consumable costs, supply chain risks, and concerns about plastic waste (leachables and extractables).

Scalability: From Benchtop to Production

A design that works at 2 liters may fail at 2,000 liters because the physics of mixing and mass transfer do not scale linearly. Maintaining a consistent power-per-unit-volume (P/V) or kLa during scale-up is a major challenge. Geometric factors, like the vessel's height-to-diameter ratio, become critical for ensuring performance is predictable at a larger scale.

Making the Right Choice for Your Application

Your choice of bioreactor design should be dictated entirely by the needs of your biological system and your operational goals.

- If your primary focus is robust microbial fermentation (e.g., E. coli, yeast): Prioritize high oxygen transfer and efficient cooling; a stainless steel, Rushton-impeller stirred-tank reactor is the classic choice.

- If your primary focus is shear-sensitive mammalian cell culture (e.g., for antibodies): Prioritize gentle mixing and precise environmental control; consider low-shear impellers, single-use systems for process security, or alternative designs like wave bioreactors.

- If your primary focus is rapid process development and flexibility: Single-use bioreactors offer a significant advantage by eliminating cleaning and validation time between runs.

Ultimately, a well-designed bioreactor is an extension of the cell culture itself, perfectly tailored to meet its every metabolic need.

Summary Table:

| Design Consideration | Key Factor | Primary Goal |

|---|---|---|

| Sterility & Materials | Aseptic Operation, Biocompatibility | Prevent contamination, ensure cell viability |

| Mass Transfer | Oxygen Supply (kLa), Agitation | Deliver nutrients/oxygen, remove waste uniformly |

| Environmental Control | Temperature, pH, Foam Management | Maintain stable, optimal growth conditions |

| System Choice | Single-Use vs. Stainless Steel, Scalability | Balance cost, flexibility, and process scale-up |

Ready to design the ideal bioreactor for your specific cell line and process?

Whether you are scaling up a microbial fermentation or developing a sensitive mammalian cell culture, the right equipment is critical to your success. KINTEK specializes in providing high-quality lab equipment and consumables to meet your exact laboratory needs.

Our experts can help you select the perfect bioreactor system—from single-use options for maximum flexibility to robust stainless-steel designs for large-scale production—ensuring optimal mass transfer, sterility, and control for your application.

Contact KINTEK today to discuss your project requirements and discover how our solutions can enhance your productivity and yield.

Visual Guide

Related Products

- High Energy Planetary Ball Mill for Laboratory Horizontal Tank Type Milling Machine

- Laboratory Planetary Ball Mill Cabinet Planetary Ball Milling Machine

- Laboratory Single Horizontal Jar Mill

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Oscillating Orbital Shaker

People Also Ask

- What is the primary function of a planetary ball mill for LLZTO targets? Achieving High-Energy Pulverization

- What role does a planetary ball mill play in the preparation of NASICON-type solid electrolytes like LATP and LAGP?

- What role does a planetary ball mill play in SHS? Optimize Powder Activation for Superior Alloy Synthesis

- What is the primary function of a planetary ball mill for NiCrAlY-Mo-Ag? Master High-Energy Mechanical Alloying

- What is the role of a planetary ball mill in the synthesis of Na3(VOPO4)2F? Enhance Your Cathode Precursor Homogeneity