In a hospital setting, autoclaves are primarily categorized by their method of air removal, which determines the types of materials they can safely sterilize. The two main types are Gravity Displacement autoclaves and Dynamic Air Removal (or Pre-vacuum) autoclaves, which are further classified under a system known as Class N, Class S, and Class B to define their specific capabilities.

The critical difference between hospital autoclaves is not their size, but how they remove air from the chamber. Choosing the right type is a matter of matching the autoclave's mechanism—gravity or vacuum—to the complexity of the instruments being sterilized, from simple solid tools to complex wrapped surgical kits.

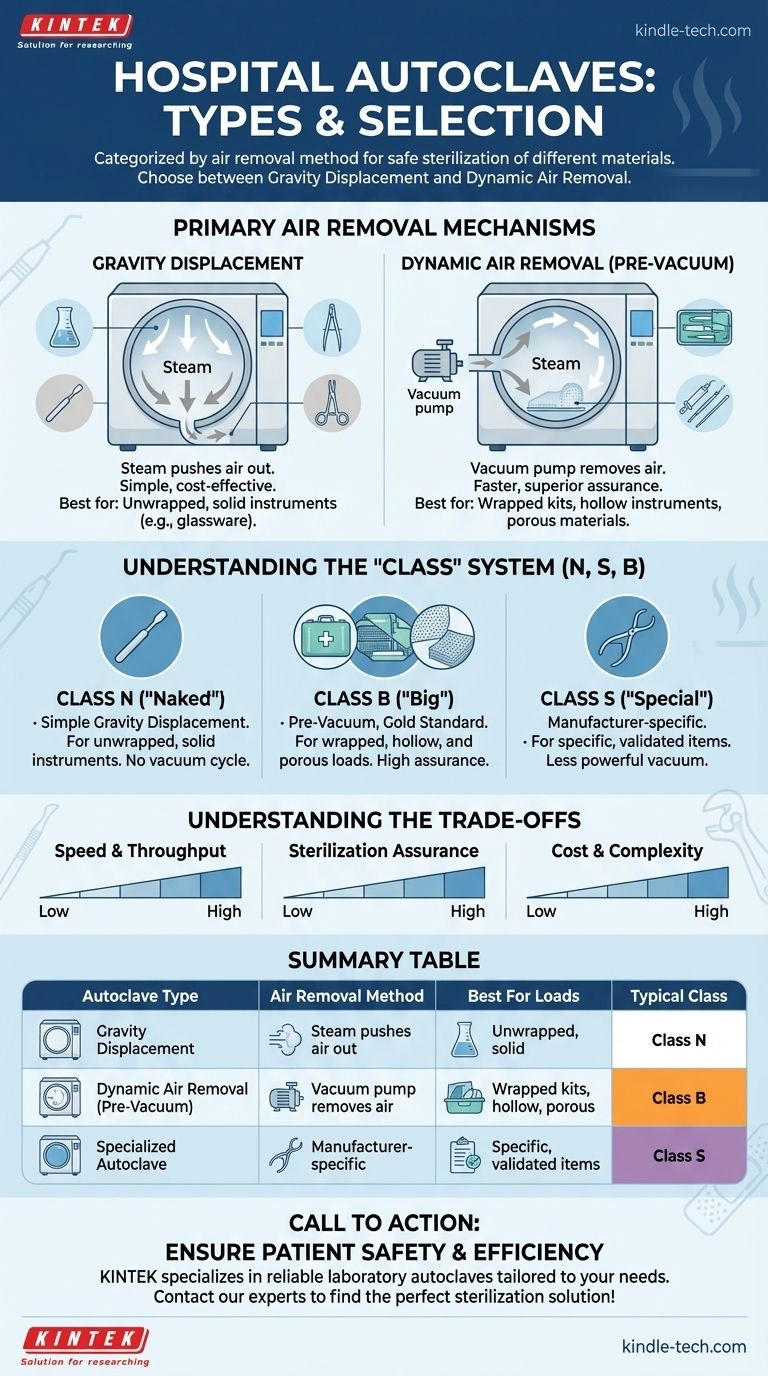

The Two Primary Mechanisms: How Air Is Removed

The effectiveness of steam sterilization depends entirely on direct contact between steam and every surface of an object. Air pockets prevent this contact, leading to sterilization failure. Therefore, the most important distinction between autoclaves is how they solve this problem.

Gravity Displacement Autoclaves

In a gravity displacement cycle, steam is introduced into the top of the autoclave chamber. Because steam is less dense than air, it displaces the heavier, cooler air, forcing it down and out through a drain at the bottom of the chamber.

This method is simple and cost-effective. However, it is only reliable for sterilizing non-porous items and simple, solid instruments that are unwrapped. It is not effective for materials with hard-to-reach surfaces, such as hollow-bore instruments or wrapped surgical kits, where air can easily become trapped.

Dynamic Air Removal (Pre-Vacuum) Autoclaves

This more advanced type uses a vacuum pump to actively remove air from the chamber before the steam is introduced. This process, often called a "pre-vacuum" cycle, ensures there are no air pockets left that could interfere with sterilization.

By creating a vacuum, steam can instantly penetrate dense, porous loads (like textiles and gowns) and reach the inner surfaces of complex or hollow instruments. These autoclaves are significantly faster and provide a higher level of sterilization assurance for a wider range of medical devices.

Understanding the "Class" System (N, S, and B)

This European classification standard is widely used to define an autoclave's performance and is directly related to its air removal method.

Class N Autoclaves

The "N" stands for "naked" solid products. These are the simplest autoclaves, typically using a gravity displacement method.

They are designed exclusively for sterilizing unwrapped, solid instruments, such as laboratory glassware or basic, non-porous tools. They do not have a vacuum cycle.

Class B Autoclaves

The "B" stands for "big" because they can sterilize the widest range of load types. These are pre-vacuum autoclaves.

A Class B cycle uses a powerful vacuum pump to remove air before sterilization and often uses a post-sterilization vacuum to facilitate drying. This is the gold standard for hospitals and dental clinics, as it is the only class proven to sterilize wrapped instruments, porous materials, and hollow instruments effectively.

Class S Autoclaves

The "S" stands for "special" or "specific." This class covers autoclaves that don't fit into the N or B categories.

A Class S autoclave is designed to sterilize specific loads as defined by the manufacturer and may include a vacuum pump that is less powerful than a Class B unit. Its performance must be validated for the particular items it is intended to process.

Understanding the Trade-offs

Choosing an autoclave involves balancing sterilization requirements with operational factors. There is no single "best" type, only the most appropriate tool for the job.

Speed and Throughput

Pre-vacuum (Class B) autoclaves are significantly faster. The active air removal and vacuum-assisted drying cycles dramatically reduce the total time needed per load, increasing the throughput of a hospital's Central Sterile Services Department (CSSD).

Sterilization Assurance

For complex loads, Class B offers superior assurance. The pre-vacuum cycle is critical for guaranteeing steam penetration into wrapped surgical trays, textiles, and cannulated instruments, which is essential for patient safety in surgical settings.

Cost and Complexity

Gravity displacement (Class N) autoclaves are simpler and less expensive. They have fewer components, making them cheaper to purchase and easier to maintain. Pre-vacuum systems involve vacuum pumps and more sophisticated controls, increasing their initial cost and long-term maintenance requirements.

Making the Right Choice for Your Goal

Your decision must be driven by the specific items you need to sterilize.

- If your primary focus is unwrapped, solid instruments (e.g., lab glassware, basic dissection tools): A Gravity Displacement (Class N) autoclave is sufficient and highly cost-effective.

- If your primary focus is wrapped surgical kits, porous loads (gowns, drapes), or hollow instruments: A Dynamic Air Removal (Class B) autoclave is mandatory to ensure effective and reliable sterilization.

- If you need high-volume processing in a central department: A large-capacity, pass-through Class B horizontal autoclave is the industry standard for a hospital's CSSD, ensuring both safety and efficiency.

Ultimately, understanding these fundamental differences is the key to ensuring both patient safety and the operational efficiency of your sterile processing workflow.

Summary Table:

| Autoclave Type | Air Removal Method | Best For Loads | Typical Class |

|---|---|---|---|

| Gravity Displacement | Steam pushes air out | Unwrapped, solid instruments (e.g., glassware) | Class N |

| Dynamic Air Removal (Pre-Vacuum) | Vacuum pump removes air | Wrapped kits, hollow instruments, porous materials | Class B |

| Specialized Autoclave | Manufacturer-specific cycle | Specific, validated items as defined by maker | Class S |

Ensure patient safety and operational efficiency with the right autoclave for your hospital or lab. KINTEK specializes in laboratory equipment and consumables, providing reliable autoclaves tailored to your sterilization needs—from simple Class N units for basic tools to high-throughput Class B systems for surgical kits. Contact our experts today to find the perfect sterilization solution!

Visual Guide

Related Products

- Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

People Also Ask

- What is the pressure bar for autoclave sterilization? Master the Critical Link Between Pressure and Temperature

- What is the purpose of treating polyester fabric in an autoclave? Ensure Reliable Results in Lab Experiments

- What is the life expectancy of an autoclave machine? Maximize Your Investment with Proper Care

- What role does an autoclave play in the acid treatment for microalgae disruption? Unlock High-Yield Cell Pretreatment

- What are the standard operating parameters for an autoclave? Master Temperature, Pressure, and Time for Sterilization