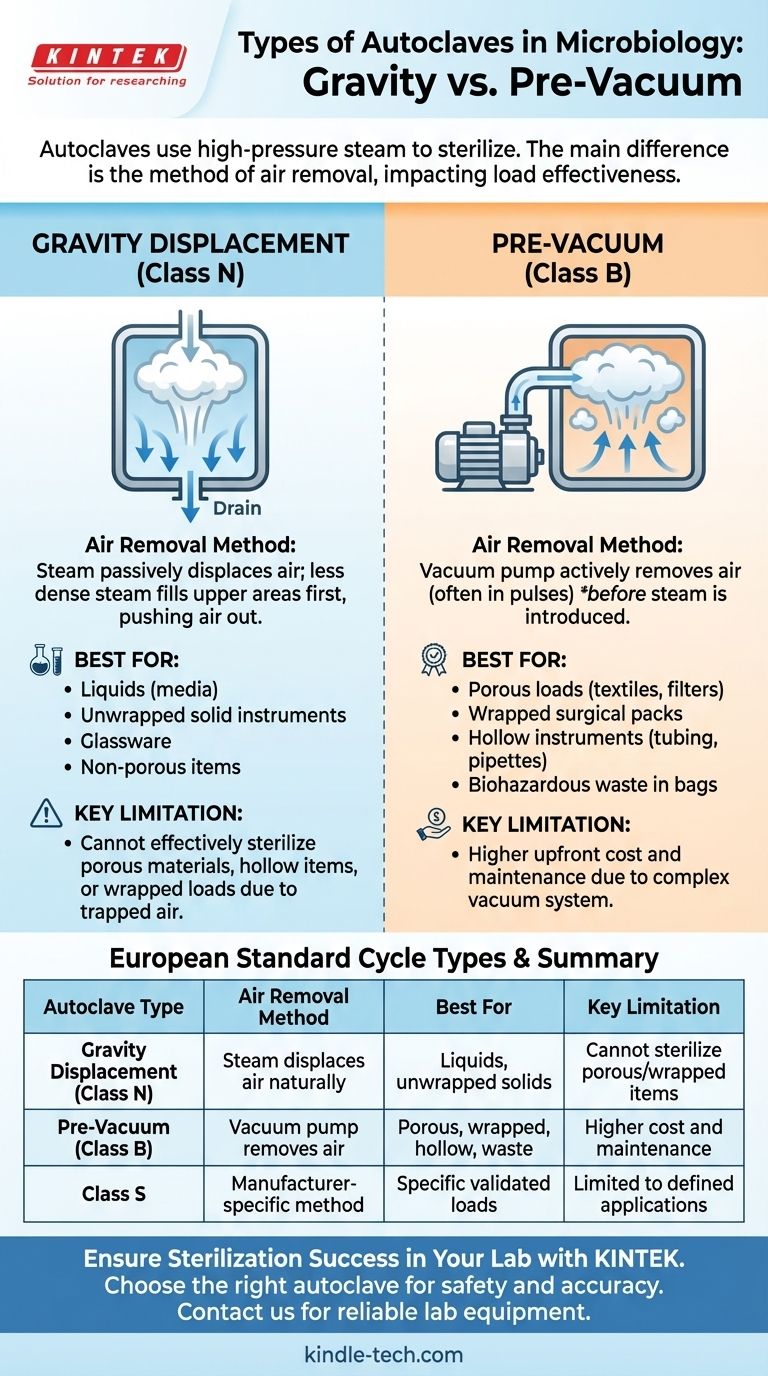

At its core, an autoclave is a pressure chamber that uses high-pressure steam to sterilize equipment and supplies. While they vary in size, the primary distinction between types of autoclaves used in microbiology lies in their method of air removal, which directly impacts their effectiveness for different kinds of loads. The two main functional types are gravity displacement and pre-vacuum (or vacuum-assisted) autoclaves.

The critical difference between autoclave types is not their size, but how they remove air from the chamber. Air is the enemy of steam sterilization, and the method used to remove it—passively by gravity or actively with a vacuum—determines which materials can be safely and effectively sterilized.

The Fundamental Principle: Air Removal is Everything

For steam to sterilize, it must make direct contact with every surface of the item. Pockets of trapped air prevent this contact, creating cold spots where microorganisms can survive. The primary engineering challenge for an autoclave is to remove all air from the chamber and the load before sterilization begins.

Type 1: Gravity Displacement Autoclaves

Gravity displacement is the simpler and more common method. In this design, steam is piped into the chamber, typically from the top or sides.

Because steam is less dense than air, it fills the upper areas first, gradually displacing the heavier, cooler air and forcing it out through a drain at the bottom of the chamber.

These autoclaves are effective and cost-efficient for sterilizing flat instruments, liquids (media), and other non-porous items where air is not easily trapped.

Type 2: Pre-Vacuum (Prevac) Autoclaves

Pre-vacuum (or prevac) autoclaves, also known as vacuum-assisted autoclaves, use a vacuum pump to actively remove air from the chamber before the steam is introduced.

This process is often done in a series of pressure and vacuum pulses to ensure all air is removed, even from within complex, hollow, or porous items.

By creating a near-perfect vacuum, the system ensures that when steam is finally introduced, it instantly penetrates the entire load, providing faster and more reliable sterilization.

Classifying Autoclaves by Application

Beyond the core mechanism, autoclaves are often categorized by their intended use and the types of cycles they can run. These classifications help users match the right machine to the specific sterilization task.

By Size and Capacity

This is the most obvious distinction. Benchtop autoclaves are small, self-contained units found in small labs, dental offices, and clinics.

Large-scale horizontal autoclaves are much larger, high-capacity machines used in hospitals and large research facilities to process hundreds of instruments or large volumes of waste at once. Either size can utilize gravity or prevac technology.

By European Standard Cycle Types (N, B, and S)

This classification precisely defines an autoclave's capability based on its air removal method.

-

Class N: The "N" stands for "naked" solid products. These autoclaves use a gravity displacement cycle and are only suitable for sterilizing unwrapped, solid instruments. They cannot be used for textiles, porous loads, or hollow items.

-

Class B: The "B" stands for "big." These are pre-vacuum autoclaves. They are suitable for sterilizing all types of loads, including porous materials, wrapped items, and hollow instruments, making them the most versatile type.

-

Class S: The "S" stands for "specific." This class covers autoclaves that don't fit into Class N or B. Their performance is validated for specific loads defined by the manufacturer and may use methods like single-phase vacuum cycles.

Understanding the Trade-offs

Choosing between autoclave types involves balancing cost, performance, and the specific needs of your laboratory workflow. Understanding the pitfalls of a mismatch is critical.

Cost vs. Capability

Gravity displacement autoclaves are mechanically simpler, making them less expensive to purchase and maintain.

Pre-vacuum systems are more expensive upfront and have more complex components, like a vacuum pump, that require maintenance. However, they provide a higher level of sterilization assurance for a wider range of materials.

Performance and Reliability

Pre-vacuum cycles are generally faster because the air removal and steam penetration are more efficient. They provide more consistent and reliable results for complex loads.

Gravity cycles are slower and are highly susceptible to user error. Improperly loading items or trying to sterilize porous materials can easily lead to trapped air and sterilization failure, a critical risk in any microbiology or clinical setting.

The Danger of a Mismatch

The most common and dangerous pitfall is using a Class N (gravity) autoclave for a load that requires a Class B (prevac) cycle. Attempting to sterilize wrapped instrument packs, tubing, or biohazard bags full of waste in a gravity unit is a recipe for failure, as steam will not penetrate the load effectively.

Making the Right Choice for Your Lab

Selecting the correct autoclave is fundamental to ensuring safety and the validity of your results. Base your decision on the most demanding items you need to sterilize.

- If your primary focus is sterilizing liquid media, glassware, and simple, unwrapped solid instruments: A gravity displacement (Class N) autoclave is a sufficient and cost-effective solution.

- If your primary focus is sterilizing porous loads (like textiles or filters), hollow items (like tubing or pipettes), or wrapped surgical packs: A pre-vacuum (Class B) autoclave is non-negotiable for ensuring sterility.

- If your primary focus is decontaminating biohazardous waste in autoclave bags: A pre-vacuum autoclave is strongly recommended to ensure complete steam penetration and kill all pathogens within the tightly packed bag.

Understanding the core principle of air removal empowers you to select the correct sterilization method for every application, ensuring the integrity and safety of your work.

Summary Table:

| Autoclave Type | Air Removal Method | Best For | Key Limitation |

|---|---|---|---|

| Gravity Displacement (Class N) | Steam displaces air naturally | Liquids, unwrapped solid instruments, glassware | Cannot sterilize porous, hollow, or wrapped items |

| Pre-Vacuum (Class B) | Vacuum pump removes air before steam | Porous loads, wrapped items, hollow instruments, waste bags | Higher cost and maintenance |

| Class S | Manufacturer-specific method | Specific loads as defined by manufacturer | Limited to validated applications |

Ensure Sterilization Success in Your Lab with KINTEK

Choosing the right autoclave is critical for the safety and accuracy of your microbiology work. Whether you need a cost-effective gravity displacement model for liquids and simple instruments or a high-performance pre-vacuum system for complex loads, KINTEK has the solution.

We specialize in providing reliable lab equipment and consumables tailored to your specific sterilization needs. Our experts can help you select the perfect autoclave to ensure complete steam penetration and eliminate contamination risks.

Contact us today to discuss your requirements and get a personalized recommendation!

Visual Guide

Related Products

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- Why is chemical sterilization sometimes used as an alternative to autoclaving? To Safely Sterilize Heat-Sensitive Equipment

- Why is an autoclave required for coal liquefaction with liquid metal catalysts? Unlocking Hydrogenation Efficiency

- What is the function of an Autoclave in paper pretreatment? Boost Saccharification Yield with Precision Heating

- What is autoclave features and uses? A Guide to Sterilization and Safety

- How does autoclave work step by step? A Guide to Reliable Sterilization

- Is autoclave a lab equipment? Essential Sterilization for Reliable Science

- Why is a PTFE-lined laboratory autoclave required for CQDs? Ensure Purity in Hydrothermal Synthesis

- Why do autoclaves work at 121°C? The Science Behind Sterilizing Bacterial Spores