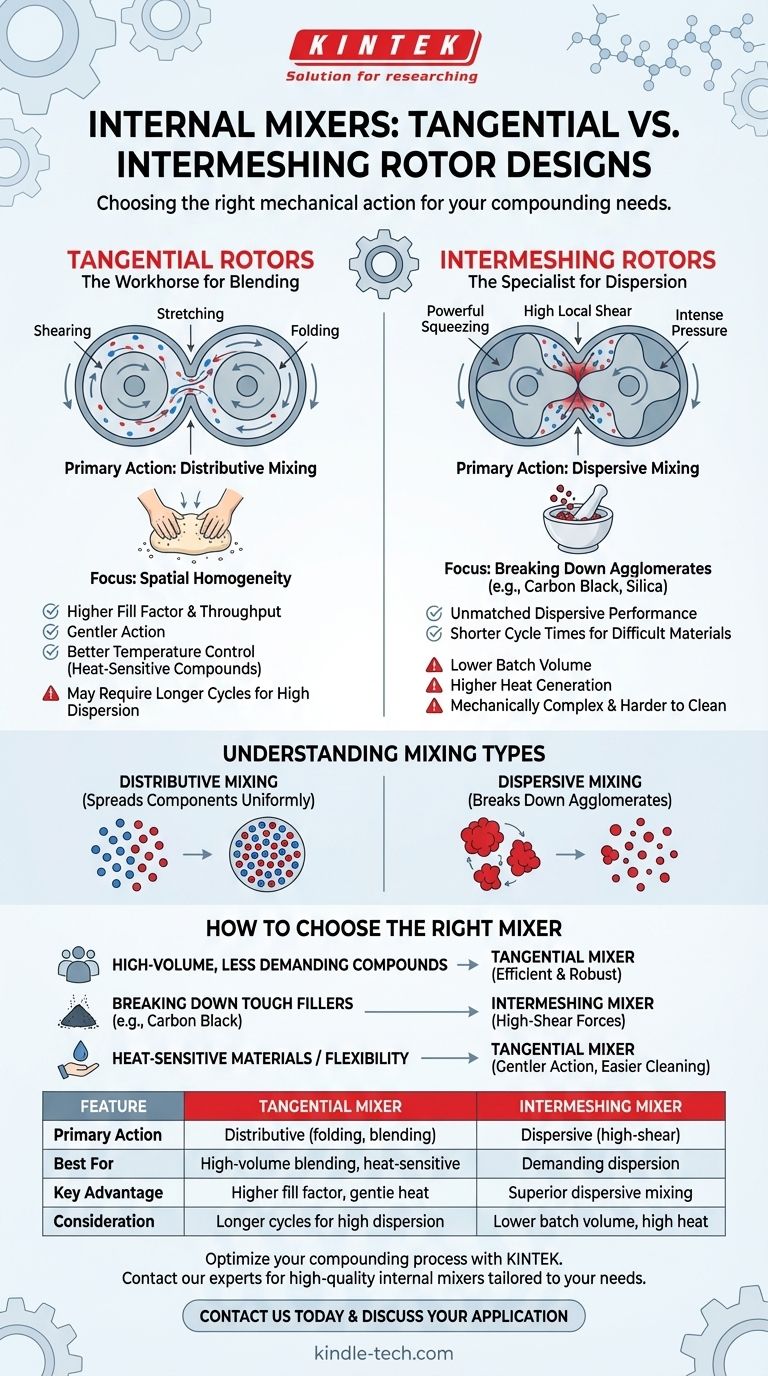

When choosing an internal mixer, your decision will come down to two fundamental designs. The primary types of internal mixers are the tangential rotor design and the intermeshing rotor design. The core difference lies in how the two mixing rotors are positioned relative to each other, which dictates the type and intensity of forces applied to the material being mixed.

The choice between tangential and intermeshing mixers is not about which is "better," but about aligning the mixer's specific mechanical action with your compound's requirements. Tangential mixers excel at folding and blending, while intermeshing mixers are specialists in generating high-shear forces to break down particles.

The Fundamental Design Difference

The geometry and interaction of the rotors are the most critical factors defining a mixer's performance. This mechanical difference directly translates into how each type processes a polymer compound.

Tangential Rotors: The Workhorse for Blending

In a tangential design, the two rotors rotate in separate, cylindrical chambers that are tangent to one another. The rotors do not touch or interpenetrate.

The primary mixing action occurs in the gap, or "nip," between each rotor and the chamber wall. Material is continuously sheared, stretched, and folded as it's pulled through these high-pressure zones.

This action is primarily distributive. Think of it like kneading dough by hand; you are constantly folding and stretching the mass to spread all the ingredients evenly.

Intermeshing Rotors: The Specialist for Dispersion

In an intermeshing design, the rotors are positioned closer together, and their lobes or wings are shaped to move through each other's space. They are synchronized to avoid clashing.

This creates a powerful squeezing and shearing action on the material trapped between the two rotors themselves. This generates extremely high local shear stress.

This action is primarily dispersive. It is analogous to using a mortar and pestle, where the goal is to grind and crush agglomerates under intense, localized pressure.

Performance: Dispersive vs. Distributive Mixing

Understanding the type of mixing your compound requires is key to selecting the right equipment. These two concepts are central to the entire field of compounding.

What is Distributive Mixing?

Distributive mixing focuses on achieving spatial homogeneity. Its goal is to spread minor components (like oils, curatives, or some fillers) uniformly throughout the polymer matrix.

It changes the location of particles but does not significantly reduce their size. Tangential mixers, with their powerful folding and reorienting action, are highly effective at this task.

What is Dispersive Mixing?

Dispersive mixing focuses on breaking down cohesive agglomerates of fillers, such as carbon black or silica, into smaller, discrete particles.

This requires generating high levels of stress to overcome the forces holding the filler particles together. The intense, localized shear of an intermeshing mixer is specifically designed to provide these forces.

Understanding the Trade-offs

Neither design is universally superior. The optimal choice depends entirely on your material, process, and final product goals. Each has distinct advantages and limitations.

Tangential Mixer Considerations

Tangential mixers often allow for a higher fill factor, meaning more material can be processed per batch, potentially increasing throughput.

Their mixing action tends to be gentler and can offer better temperature control, which is a significant advantage for heat-sensitive compounds that might scorch under high shear.

However, they may struggle to achieve the highest levels of dispersion required for demanding applications, sometimes necessitating longer mixing cycles to compensate.

Intermeshing Mixer Considerations

Intermeshing mixers provide unmatched dispersive mixing performance, often achieving quality targets in shorter cycle times for difficult-to-disperse materials.

This high efficiency comes at a cost. They typically have a lower batch volume and the intense shear can generate significant heat, increasing the risk of material degradation if not carefully controlled.

They are also mechanically more complex and can be more challenging to clean thoroughly between batches, which is a consideration for producers running many different compounds.

How to Choose the Right Mixer for Your Compound

Your choice should be a direct reflection of your primary compounding objective.

- If your primary focus is high-volume production and distributive blending of less-demanding compounds: A tangential mixer is typically the more efficient and robust choice.

- If your primary focus is breaking down tough fillers like carbon black for high-performance applications: An intermeshing mixer will provide the necessary high-shear forces for superior dispersion.

- If you are working with heat-sensitive materials or require maximum batch-to-batch flexibility: The gentler action and easier cleaning of a tangential mixer may be preferable.

Understanding the fundamental difference in rotor design empowers you to select the precise tool needed to meet your specific compounding objectives.

Summary Table:

| Feature | Tangential Mixer | Intermeshing Mixer |

|---|---|---|

| Primary Mixing Action | Distributive (folding, blending) | Dispersive (high-shear, particle breakdown) |

| Best For | High-volume blending, heat-sensitive materials | Demanding dispersion (e.g., carbon black) |

| Key Advantage | Higher fill factor, gentler heat generation | Superior dispersive mixing, shorter cycles |

| Consideration | May require longer cycles for high dispersion | Lower batch volume, higher heat generation |

Optimize your compounding process with the right equipment. Selecting the correct internal mixer is critical for achieving your product's quality and performance goals. KINTEK specializes in providing high-quality lab equipment and consumables, including internal mixers tailored to your specific polymer and material science needs. Our experts can help you choose the perfect solution for efficient blending or high-shear dispersion. Contact us today to discuss your application and get a personalized recommendation! Reach out via our contact form

Visual Guide

Related Products

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

- Laboratory Oscillating Orbital Shaker

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

People Also Ask

- What is the primary purpose of using an orbital shaker during metal ion adsorption? Optimize PAF Performance

- What role does high-speed stirring equipment play in fungal pre-cultures? Optimize Your Solid-State Fermentation

- What is the function of a laboratory shaker during batch adsorption experiments? Optimize Fly Ash Kinetic Research

- Why is a high-precision orbital shaker required for chitin adsorption? Achieve Rapid Equilibrium & Precise Data

- What is the role of laboratory stirring equipment in nZVI preparation? Achieve Stable and Uniform Nano Slurries