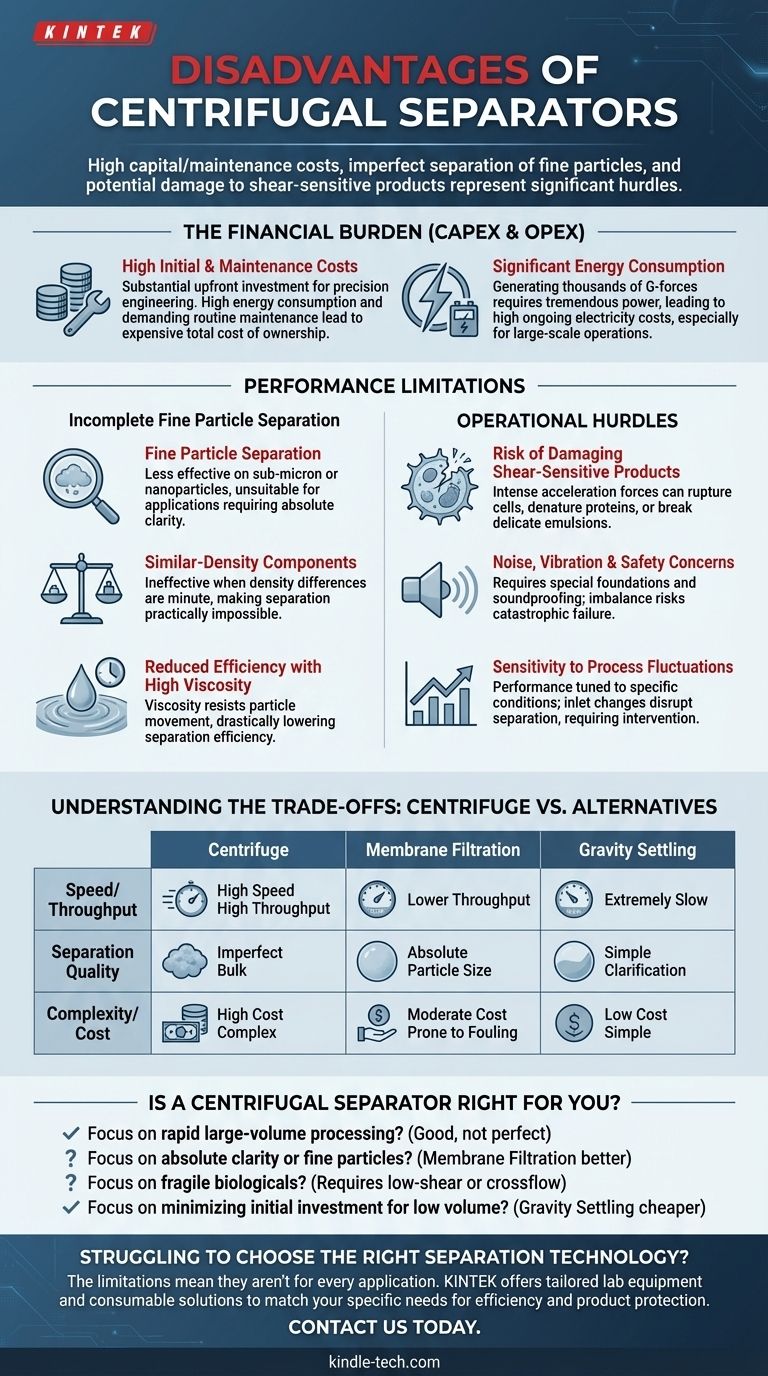

In short, the primary disadvantages of centrifugal separators are their high capital and maintenance costs, their inability to achieve perfect separation of very fine particles, and their potential to damage shear-sensitive products. These machines represent a significant investment in both money and operational expertise, and they are not a universal solution for every separation task.

While unmatched in speed and throughput for separating components of different densities, the power of a centrifuge comes with significant trade-offs. The core challenge is not whether a centrifuge can separate a mixture, but whether its high costs and inherent limitations make it the right tool for your specific application and product.

The Financial Burden: High Capital and Operational Costs

Centrifugal separators are sophisticated pieces of rotating equipment, and their costs reflect this complexity. The financial commitment extends far beyond the initial purchase price.

High Initial Investment (CAPEX)

A centrifuge is a precision-engineered machine designed to withstand immense forces. The use of high-strength materials, advanced balancing, powerful motors, and complex control systems results in a substantial upfront capital cost compared to simpler alternatives like static settlers or basic filtration units.

Significant Energy Consumption

Generating thousands of G-forces requires a tremendous amount of energy. The motor needed to accelerate and maintain the high rotational speed of the centrifuge bowl is a major power consumer, leading to high ongoing electricity costs, especially in continuous, large-scale operations.

Demanding Maintenance Requirements (OPEX)

These are not "set-and-forget" devices. High-speed rotation causes inevitable wear on components like bearings, seals, and drive parts. Routine maintenance is critical for safety and performance, often requiring specialized technicians and expensive replacement parts, contributing significantly to the total cost of ownership.

Fundamental Performance Limitations

No separation technology is perfect, and it is crucial to understand where centrifuges fall short. Their effectiveness is fundamentally tied to the physical properties of the mixture being processed.

Incomplete Separation of Fine Particles

Centrifugal force is less effective on very small (sub-micron) particles or nanoparticles. While excellent for bulk separation, a centrifuge will not produce a perfectly clear liquid (supernatant). A certain amount of fine solids will almost always remain, making it unsuitable for applications requiring absolute clarity.

Challenges with Similar-Density Components

The driving principle of centrifugation is a difference in density. When two liquid phases or a solid and a liquid have very similar densities, the force required for effective separation becomes enormous, often making it impractical or impossible.

Reduced Efficiency with High Viscosity

A fluid's viscosity resists the movement of particles. In highly viscous liquids, particles cannot migrate to the centrifuge wall easily, drastically reducing separation efficiency and requiring longer residence times or higher G-forces, which increases cost and complexity.

Operational and Environmental Hurdles

Beyond cost and performance, the day-to-day reality of running a centrifuge presents its own set of challenges that must be planned for.

Risk of Damaging Shear-Sensitive Products

The intense acceleration and shear forces inside a centrifuge can be destructive. This is a major drawback in biotechnology and food production, where the process can rupture cells, denature proteins, or break delicate emulsions, thereby destroying or degrading the final product.

Noise, Vibration, and Safety Concerns

High-speed centrifuges generate significant noise and vibration, which may necessitate special foundations, sound-dampening enclosures, and worker protection. More importantly, they are high-energy machines. An imbalance in the rotating bowl can lead to catastrophic failure, making strict adherence to safety protocols and interlock systems non-negotiable.

Sensitivity to Process Fluctuations

The efficiency of a centrifuge is often tuned for a specific feed rate, concentration, and temperature. Any significant fluctuation in these inlet conditions can disrupt the separation process, leading to a decline in performance and requiring operator intervention to re-optimize the system.

Understanding the Trade-offs: Centrifuge vs. Alternatives

Choosing a centrifuge means prioritizing certain benefits while accepting its inherent drawbacks. Understanding how it compares to other methods is key.

Speed vs. Finesse: Centrifuge vs. Filtration

A centrifuge offers high-speed, continuous processing but provides imperfect separation. In contrast, membrane filtration offers absolute separation based on particle size (finesse) but typically operates at a much lower throughput and can be prone to fouling.

Throughput vs. Simplicity: Centrifuge vs. Gravity Settling

A centrifuge accelerates gravity to process large volumes in a compact footprint. Gravity settling tanks or clarifiers achieve the same goal using only natural gravity. They are simple, cheap, and have no moving parts, but they are extremely slow and require a massive physical footprint for the same throughput.

Is a Centrifuge Right for Your Application?

To make the right choice, you must weigh the disadvantages against your primary operational goal.

- If your primary focus is rapidly processing large volumes where good, not perfect, separation is sufficient: A centrifuge is an excellent candidate worth the investment.

- If your primary focus is achieving absolute clarity or removing extremely fine particles: Membrane filtration is almost certainly a more appropriate technology.

- If your primary focus is processing fragile biologicals or shear-sensitive emulsions: You must carefully evaluate if a low-shear centrifuge model is suitable, or if a gentler method like crossflow filtration is required.

- If your primary focus is minimizing initial investment for a low-volume process: Simple batch filtration or gravity settling will be far more economical.

Understanding these limitations is the first step toward selecting the most effective and economical separation technology for your specific challenge.

Summary Table:

| Disadvantage Category | Key Challenges |

|---|---|

| Financial Burden | High initial investment (CAPEX), significant energy consumption, demanding maintenance (OPEX) |

| Performance Limitations | Incomplete separation of fine particles, struggles with similar-density components, reduced efficiency in high-viscosity fluids |

| Operational Hurdles | Risk of damaging shear-sensitive products, noise and vibration, sensitivity to process fluctuations |

Struggling to choose the right separation technology for your lab? The limitations of centrifugal separators—like high costs and potential product damage—mean they aren't the perfect fit for every application. At KINTEK, we specialize in lab equipment and consumables, offering tailored solutions that match your specific separation needs, whether you require gentle handling for sensitive samples or absolute clarity for fine particles. Let our experts help you optimize your process efficiency and protect your valuable products. Contact us today to find the ideal equipment for your laboratory!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

- Custom PTFE Teflon Parts Manufacturer for Centrifuge Tube Racks

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What are the two methods of control of corrosion? Master the Strategies for Metal Protection

- Are diamonds used in machines? Unlock Superior Performance with Diamond Tools

- Why is it necessary to use a high-precision mass flow controller (MFC) in CO2 reduction? Ensure Accurate SPCE Data

- How much energy does hot isostatic pressing consume? Unlock Net Energy Savings in Your Process

- What is air melt? A Guide to Standard Steel Production and Its Alternatives

- Which is the most applied area for additive manufacturing? From Prototyping to High-Value Production

- What is the difference between RF and DC power? Choosing the Right Power for Your Application

- What is the sintering process of coating? Building Durable, Solid Layers from Powder