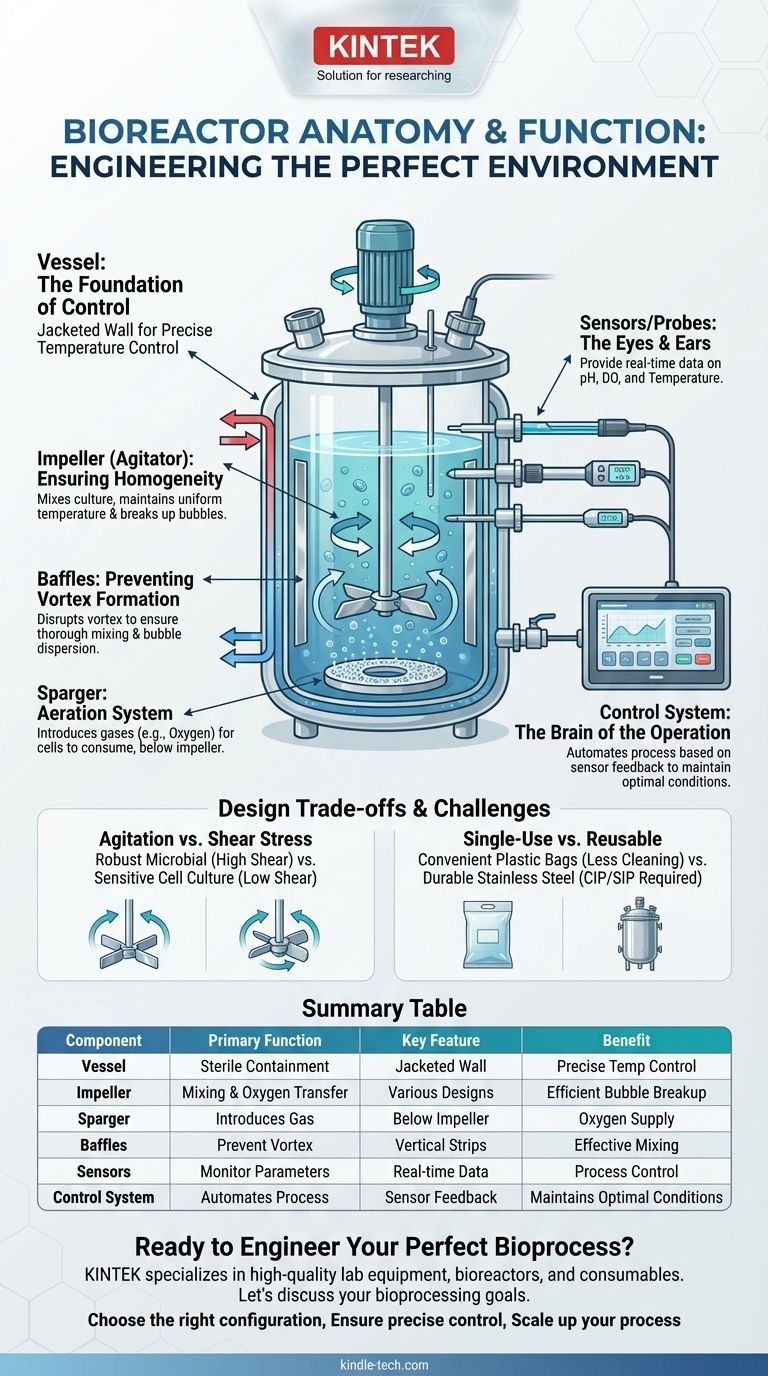

At its core, a bioreactor is a meticulously engineered vessel designed to create the perfect environment for a biological process. It is far more than a simple container; it is a dynamic system composed of several critical parts working in concert, including the vessel itself, an agitation system (impeller), an aeration system (sparger), baffles to ensure proper mixing, and a suite of sensors tied to a central control unit.

Understanding the individual parts of a bioreactor is less about creating a checklist and more about seeing how each component is a tool to control a specific environmental parameter—like oxygen, temperature, or pH—to maximize the productivity and health of living cells.

The Core Components: Form and Function

A bioreactor’s primary job is to provide a controlled, sterile, and homogeneous environment. This is achieved through the coordinated action of its fundamental hardware components.

The Vessel: The Foundation of Control

The vessel is the physical containment unit for the bioprocess. For lab-scale research, this is often a borosilicate glass container, while industrial-scale production almost exclusively uses stainless steel.

Its design is critical. Many vessels feature a jacketed wall, which is a secondary outer wall that allows a heating or cooling fluid (like water or glycol) to circulate, providing precise temperature control for the culture inside.

The Agitation System: Ensuring Homogeneity

The impeller (or agitator) is the component responsible for mixing. It is mounted on a central shaft and driven by an external motor.

Its primary functions are to keep the cells and nutrients evenly suspended, maintain a uniform temperature throughout the vessel, and break up gas bubbles to enhance oxygen transfer from the gas phase into the liquid media. Different impeller designs, like the Rushton turbine or marine propeller, are chosen based on the specific mixing and shear-stress requirements of the cells.

The Aeration System: Supplying Critical Gases

The sparger is the device that introduces gas into the liquid culture. It is typically located at the bottom of the vessel, directly below the impeller.

For aerobic cultures, the sparger bubbles in air or pure oxygen. The impeller then chops these large bubbles into smaller ones, dramatically increasing the surface area for oxygen to dissolve into the media where the cells can consume it.

Baffles: Preventing Vortex Formation

Baffles are vertical strips of metal attached to the inner wall of the vessel. Without them, the spinning motion of the impeller would create a central vortex, similar to water draining from a tub.

This vortex is highly inefficient for mixing. Baffles disrupt this swirling flow, creating turbulence that ensures the entire volume of the vessel is mixed thoroughly and that gas bubbles are dispersed effectively rather than being sucked into the vortex.

The Sensory System: The Eyes and Ears

A bioreactor is blind without its probes and sensors. These devices are inserted into the vessel through sterile ports to provide real-time data on the state of the culture.

The most critical sensors measure pH, dissolved oxygen (DO), and temperature. This data stream is the essential feedback loop that allows for automated process control. Other sensors may measure pressure, foam levels, or even cell density.

The Control System: The Brain of the Operation

The control system is the central computer and software that automates the entire process. It continuously reads the data from the sensors and makes decisions to maintain optimal conditions.

For example, if the DO sensor detects that oxygen levels are dropping, the controller can automatically increase the agitation speed or the gas flow rate through the sparger. If the pH drifts, the controller activates pumps to add a precise amount of acid or base.

Understanding Design Trade-offs and Challenges

Choosing and operating a bioreactor involves balancing competing factors. Understanding these trade-offs is key to successful bioprocessing.

Agitation vs. Shear Stress

While vigorous agitation is excellent for mixing and oxygen transfer, it also creates high shear stress. Robust microbial cells like bacteria and yeast can easily handle this.

However, more fragile mammalian or insect cells can be damaged or killed by excessive shear. For these applications, engineers must choose low-shear impellers and operate them at lower speeds, creating a different set of challenges for ensuring adequate oxygen supply.

Single-Use vs. Reusable Vessels

Traditional reusable bioreactors are made of stainless steel. They are durable and can be very large, but require intensive cleaning and sterilization-in-place (CIP/SIP) procedures between batches, which is time-consuming and expensive.

Single-use bioreactors, which are essentially pre-sterilized plastic bags held in a supporting frame, have become dominant in clinical manufacturing. They eliminate cleaning, reduce cross-contamination risk, and offer faster turnaround, but generate plastic waste and are often limited in maximum volume.

Sensor Accuracy and Sterility

Probes must be both highly accurate and robust enough to survive sterilization, typically via high-pressure steam in an autoclave. Maintaining the calibration and integrity of a delicate pH or DO probe after repeated sterilization cycles is a significant engineering challenge.

Making the Right Choice for Your Goal

The ideal bioreactor configuration depends entirely on the biological system you are working with and your ultimate objective.

- If your primary focus is robust microbial fermentation (e.g., E. coli): Prioritize a system with powerful agitation and high-capacity aeration, as maximizing oxygen transfer is often the key to high-density cultures.

- If your primary focus is sensitive cell culture (e.g., mammalian cells for antibodies): Select a system with low-shear impellers and a sophisticated control system capable of tight, precise regulation of pH and dissolved oxygen.

- If your primary focus is process development and scale-up: Choose a system with industry-standard geometry and controls to ensure that the results you achieve in the lab can be reliably replicated at pilot and production scales.

By understanding how each part contributes to the whole, you can move from simply using a bioreactor to truly engineering a successful biological process.

Summary Table:

| Component | Primary Function | Key Feature |

|---|---|---|

| Vessel | Sterile containment for the bioprocess | Jacketed wall for temperature control |

| Impeller (Agitator) | Mixing and oxygen transfer | Various designs (e.g., Rushton turbine) for different shear needs |

| Sparger | Introduces gas (e.g., oxygen) into the culture | Located below impeller for efficient bubble breakup |

| Baffles | Prevents vortex formation for effective mixing | Vertical strips on the inner vessel wall |

| Sensors/Probes | Monitor key parameters (pH, DO, temperature) | Provide real-time data for process control |

| Control System | Automates the process based on sensor data | The 'brain' that maintains optimal conditions |

Ready to Engineer Your Perfect Bioprocess?

Understanding the components is the first step. Selecting the right bioreactor system is critical to the success of your research or production. KINTEK specializes in providing high-quality lab equipment, including bioreactors and consumables, tailored to your specific biological system—whether you're working with robust microbial cultures or sensitive mammalian cells.

We can help you:

- Choose the right configuration for your application (microbial fermentation, cell culture, etc.).

- Ensure precise control over critical parameters like temperature, pH, and dissolved oxygen.

- Scale up your process with confidence from lab to pilot scale.

Let's discuss your bioprocessing goals. Contact our experts today to find the ideal bioreactor solution for your laboratory needs.

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for PTFE Ball Valve Seat

- Custom PTFE Teflon Parts Manufacturer for Hydrothermal Synthesis Reactor Polytetrafluoroethylene Carbon Paper and Carbon Cloth Nano-growth

- Custom PTFE Teflon Parts Manufacturer for Non-Standard Insulator Customization

- Laboratory Hybrid Tissue Grinding Mill

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

People Also Ask

- How can you increase the pressure in a reactor? Master the Methods for Optimal Chemical Process Control

- Why are high-precision pressure sensors and temperature control systems critical for hydrothermal reaction equilibrium?

- What are the advantages of using laboratory-grade stirred reactors for glucose oxidation? Boost Mass Transfer Efficiency

- What process conditions does a hydrothermal synthesis reactor provide for Mg(GLY) MOFs? Ensure Precision Synthesis

- What is the mechanism of high-pressure hydrothermal treatment in HA catalysts? Optimize Mesoporous Structure Today

- How do the preheater and test chamber in a steam corrosion test system work together? Master High-Temp Simulation

- How do high-pressure steam explosion reactors improve efficiency during the lignin separation process? (Expert Guide)

- How does a high-pressure stainless steel reactor function during the non-isothermal autohydrolysis of biomass mixtures?