In short, bio-oil can be produced from nearly any type of biomass. The most common and effective raw materials are lignocellulosic biomass, which is the dry, structural matter of plants. This includes materials like wood waste, agricultural residues such as corn stalks, and specific energy crops grown for fuel production.

The choice of raw material is the single most important factor determining the economic viability of a bio-oil project and the quality of the final fuel. The ideal feedstock is not just organic matter; it is abundant, low-cost, and has specific chemical and physical properties that favor efficient conversion.

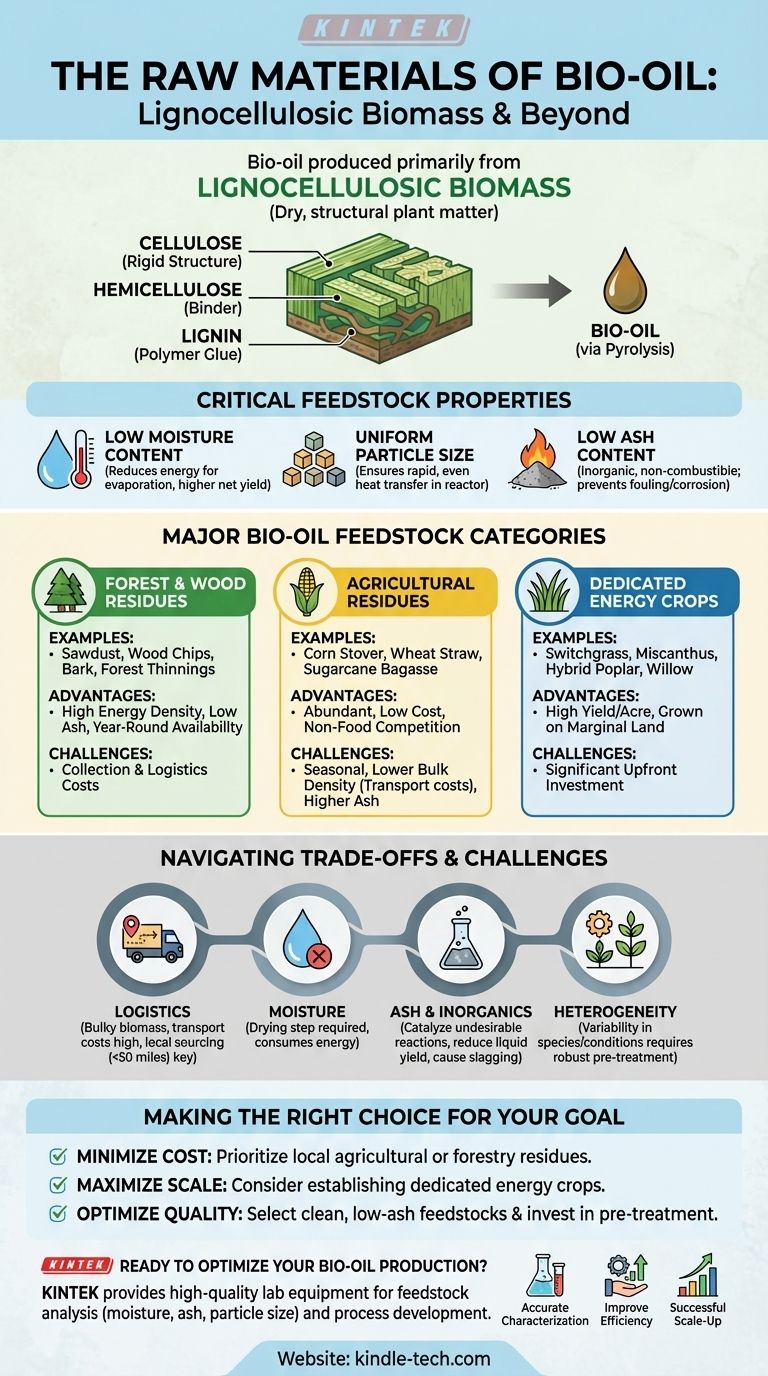

What Defines a Viable Bio-oil Feedstock?

Not all biomass is created equal. The efficiency of the pyrolysis process—the high-temperature decomposition of organic material in the absence of oxygen to produce bio-oil—is highly dependent on the characteristics of the raw material.

The Lignocellulosic Core

The primary components of interest in biomass are cellulose, hemicellulose, and lignin. These complex polymers make up the rigid cell walls of plants. During pyrolysis, their decomposition forms the mixture of oxygenated organic compounds that we call bio-oil. A high concentration of these three components is the first indicator of a good feedstock.

Critical Physical Properties

The physical state of the biomass directly impacts process efficiency. The two most important factors are moisture content and particle size. High moisture content requires significant energy to evaporate the water before pyrolysis can begin, reducing the net energy yield. Biomass must also be ground to a small, uniform particle size to ensure rapid and even heat transfer within the reactor.

Essential Chemical Properties

The chemical makeup, beyond the core polymers, is critical. A low ash content is highly desirable. Ash is the inorganic, non-combustible portion of the biomass (e.g., silica, potassium, sodium). High ash levels can lower bio-oil yield, act as an unwanted catalyst, and cause operational problems like fouling and corrosion in equipment.

Major Categories of Bio-oil Feedstocks

Biomass resources are typically grouped into three main categories, each with its own set of advantages and disadvantages.

Forest and Wood Residues

This category includes materials from forestry operations and wood processing industries, such as sawdust, wood chips, bark, and forest thinnings. Woody biomass is often considered an excellent feedstock due to its high energy density, low ash content, and year-round availability.

Agricultural Residues

These are the byproducts left in the field after a harvest. Common examples include corn stover (stalks, leaves), wheat straw, and sugarcane bagasse. These materials are attractive because they are abundant and do not compete with food production. However, they are often seasonal, have a lower bulk density (making transport expensive), and can have higher ash content than wood.

Dedicated Energy Crops

These are fast-growing, non-food plants cultivated specifically for energy production. Examples include perennial grasses like switchgrass and miscanthus, or short-rotation woody crops like hybrid poplar and willow. They offer the potential for very high yields per acre and can be grown on marginal lands unsuitable for traditional agriculture.

Understanding the Trade-offs and Challenges

Selecting a feedstock involves navigating a complex set of economic and technical trade-offs. What works in one region may be entirely impractical in another.

The Tyranny of Logistics

Biomass is bulky and has a low energy density compared to fossil fuels. The cost of collection, storage, and transportation is a major economic driver. As a rule of thumb, most viable bio-refineries must source the majority of their feedstock from within a 50-mile radius to remain profitable.

The Problem with Water

Excess moisture is a primary enemy of efficient pyrolysis. Any water in the feedstock must be vaporized, which consumes a large amount of energy that could otherwise be used for the conversion process. This is why a drying step is almost always required, adding cost and complexity.

The Impact of Ash and Inorganics

High concentrations of inorganic elements, particularly alkali metals like potassium and sodium, can be detrimental. These elements can act as catalysts that favor the production of gas and char over liquid bio-oil, reducing your primary product yield. They also contribute to slagging and fouling, which can shut down a reactor.

Feedstock Heterogeneity

Unlike crude oil, biomass is not a uniform commodity. Its properties can vary significantly based on species, growing conditions, and harvest time. This variability requires a robust and often expensive pre-treatment process (drying, grinding, and sometimes blending) to create a consistent input for the pyrolysis reactor.

Making the Right Choice for Your Goal

The "best" raw material is entirely dependent on your strategic objective. Your decision should be based on a clear-eyed assessment of local resources and project goals.

- If your primary focus is minimizing feedstock cost: Prioritize locally abundant agricultural or forestry residues that require minimal transportation and have no competing market value.

- If your primary focus is maximizing scale and consistency: Consider establishing dedicated energy crops, but be prepared for the significant upfront investment and land-use considerations.

- If your primary focus is optimizing bio-oil quality and process stability: Select clean, low-ash feedstocks like de-barked wood and invest in a thorough pre-treatment system to control moisture and particle size.

Ultimately, a successful bio-oil strategy is built not on a single "perfect" material, but on a deep understanding of the interplay between local resources, logistics, and conversion technology.

Summary Table:

| Feedstock Category | Common Examples | Key Advantages | Key Challenges |

|---|---|---|---|

| Forest/Wood Residues | Sawdust, Wood Chips, Bark | High energy density, Low ash content, Year-round availability | Requires collection/logistics |

| Agricultural Residues | Corn Stover, Wheat Straw, Bagasse | Abundant, Low cost, No food competition | Seasonal, Lower bulk density, Higher ash |

| Dedicated Energy Crops | Switchgrass, Miscanthus, Poplar | High yield per acre, Grown on marginal land | Significant upfront investment |

Ready to optimize your bio-oil production process?

The right lab equipment is critical for analyzing feedstock properties like moisture content, ash composition, and particle size to ensure efficient pyrolysis. KINTEK specializes in providing high-quality lab equipment and consumables for biomass analysis and process development.

We help our laboratory customers:

- Accurately characterize biomass feedstocks for optimal selection.

- Improve process efficiency with reliable analysis tools.

- Scale up successfully from lab bench to pilot plant.

Contact us today via our [#ContactForm] to discuss how our solutions can support your bio-fuel research and production goals.

Visual Guide

Related Products

People Also Ask

- What is the future scope of pyrolysis? Unlocking Circular Economy Potential with Waste-to-Resource Tech

- What is sintering effect? Transform Powder into Durable, High-Performance Parts

- Is pyrolysis oil flammable? Understanding Its Combustible Nature and Critical Safety Risks

- What is the function of a laboratory constant temperature drying oven in rice husk analysis? Ensure Precise Dry Weight

- How do vacuum pumps enhance efficiency and performance? Boost Your System's Speed and Lower Costs

- What are the techniques of sintering? Choose the Right Method for Your Material

- What is the difference between RF and DC sputtering? Choose the Right Method for Your Material

- How do microwave synthesis reactors compare to traditional heating methods? Faster, Greener Nanoparticle Synthesis