The standard frequency for RF sputtering is 13.56 MHz. This specific frequency is not chosen at random; it is an internationally designated standard that ensures the process is both physically effective for creating thin films and compliant with global telecommunications regulations.

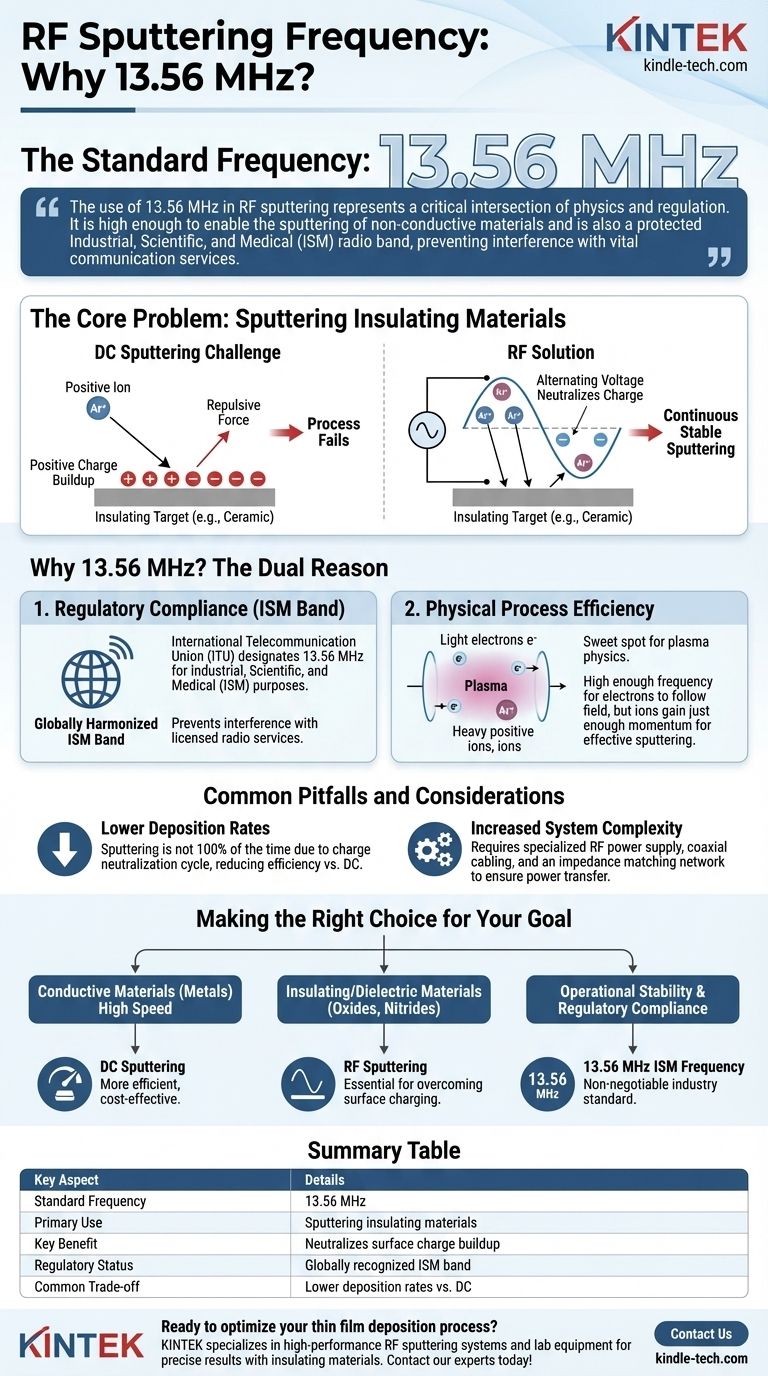

The use of 13.56 MHz in RF sputtering represents a critical intersection of physics and regulation. It is high enough to enable the sputtering of non-conductive materials and is also a protected Industrial, Scientific, and Medical (ISM) radio band, preventing interference with vital communication services.

The Core Problem: Sputtering Insulating Materials

To understand the need for radio frequency, we must first look at the fundamental limitation of its predecessor, Direct Current (DC) sputtering.

The Challenge of Positive Charge Buildup

In any sputtering process, positively charged gas ions (typically argon) are accelerated toward a target material to physically eject atoms, which then deposit onto a substrate.

With a conductive target, a DC power supply works perfectly. The target simply conducts away the positive charge delivered by the ions.

However, if the target is an insulating material (like a ceramic or oxide), this positive charge accumulates on the surface. This buildup quickly repels incoming positive ions, effectively shutting down the sputtering process.

How RF Provides the Solution

Applying a Radio Frequency (RF) alternating current solves this problem by rapidly switching the voltage on the target.

During one half-cycle, the target is negatively biased, attracting positive ions for sputtering. In the next half-cycle, it becomes positively biased, attracting a flood of electrons from the plasma.

These electrons neutralize the positive charge that built up on the insulating target's surface, preparing it for the next sputtering cycle. This rapid oscillation, happening millions of times per second, allows for a continuous and stable sputtering process.

Why the Specific Frequency of 13.56 MHz?

While any frequency above ~1 MHz can technically overcome the charging effect, the choice of 13.56 MHz is deliberate and based on two critical factors.

1. Regulatory Compliance (The ISM Band)

The most significant reason is regulatory. Radio frequencies are heavily regulated to prevent interference with communication, navigation, and broadcast systems.

The International Telecommunication Union (ITU) designates specific frequencies for Industrial, Scientific, and Medical (ISM) purposes.

13.56 MHz is the primary globally harmonized ISM band for this type of application. Using this frequency ensures that the powerful RF generator in a sputtering system does not disrupt licensed radio services.

2. Physical Process Efficiency

This frequency also sits in a "sweet spot" for the physics of the plasma.

It is high enough that the much lighter electrons in the plasma can easily follow the alternating field, while the heavier positive argon ions cannot.

This mass difference is key. The ions gain just enough momentum from the field to strike the target with sufficient energy for effective sputtering, ensuring a high-quality thin film deposition.

Common Pitfalls and Considerations

While essential for insulators, RF sputtering is not without its own set of complexities and trade-offs compared to DC methods.

Lower Deposition Rates

Generally, RF sputtering yields lower deposition rates than DC sputtering. The process of neutralizing the target each cycle means that sputtering is not occurring 100% of the time, slightly reducing overall efficiency.

Increased System Complexity

RF systems are inherently more complex. They require a specialized RF power supply, coaxial cabling, and a crucial component called an impedance matching network.

This network is necessary to ensure maximum power is transferred from the generator to the plasma, and improper tuning can lead to reflected power, process instability, and even equipment damage.

Making the Right Choice for Your Goal

Understanding the role of frequency helps you select the correct deposition technique for your specific application.

- If your primary focus is depositing conductive materials (like metals) at high speed: Standard DC sputtering is often the more efficient and cost-effective choice.

- If your primary focus is depositing insulating or dielectric materials (like oxides or nitrides): RF sputtering is the essential and industry-standard technique required to overcome surface charging.

- If your primary focus is maintaining operational stability and regulatory compliance: Using the standard 13.56 MHz ISM frequency is the non-negotiable path for nearly all commercial and research applications.

Ultimately, the choice of frequency in RF sputtering is a perfect example of how technical processes are shaped by both fundamental physics and practical, real-world constraints.

Summary Table:

| Key Aspect | Details |

|---|---|

| Standard Frequency | 13.56 MHz |

| Primary Use | Sputtering insulating materials (ceramics, oxides) |

| Key Benefit | Neutralizes surface charge buildup, enabling stable deposition |

| Regulatory Status | Globally recognized ISM (Industrial, Scientific, Medical) band |

| Common Trade-off | Lower deposition rates vs. DC sputtering |

Ready to optimize your thin film deposition process? KINTEK specializes in high-performance RF sputtering systems and lab equipment designed for precise, reliable results with insulating materials. Our expertise ensures you get the right solution for your specific application, backed by industry-leading support. Contact our experts today to discuss how our equipment can enhance your research or production capabilities!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RRDE rotating disk (ring disk) electrode / compatible with PINE, Japanese ALS, Swiss Metrohm glassy carbon platinum

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1200℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What is the plasma CVD process? Achieve Low-Temperature Thin Film Deposition

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition