At its core, a filter tester is a specialized instrument designed to measure the performance and efficiency of a filter. It works by generating a controlled stream of particles (an aerosol), passing it through the filter material, and precisely measuring the particle concentration both before and after the filter. This comparison determines exactly how effective the filter is at capturing contaminants.

A filter tester is more than a measurement device; it is a tool for validation and quality assurance. Its primary purpose is to provide objective, repeatable data on how effectively a filter separates particles from a fluid (typically air), ensuring it meets critical performance, safety, and regulatory standards.

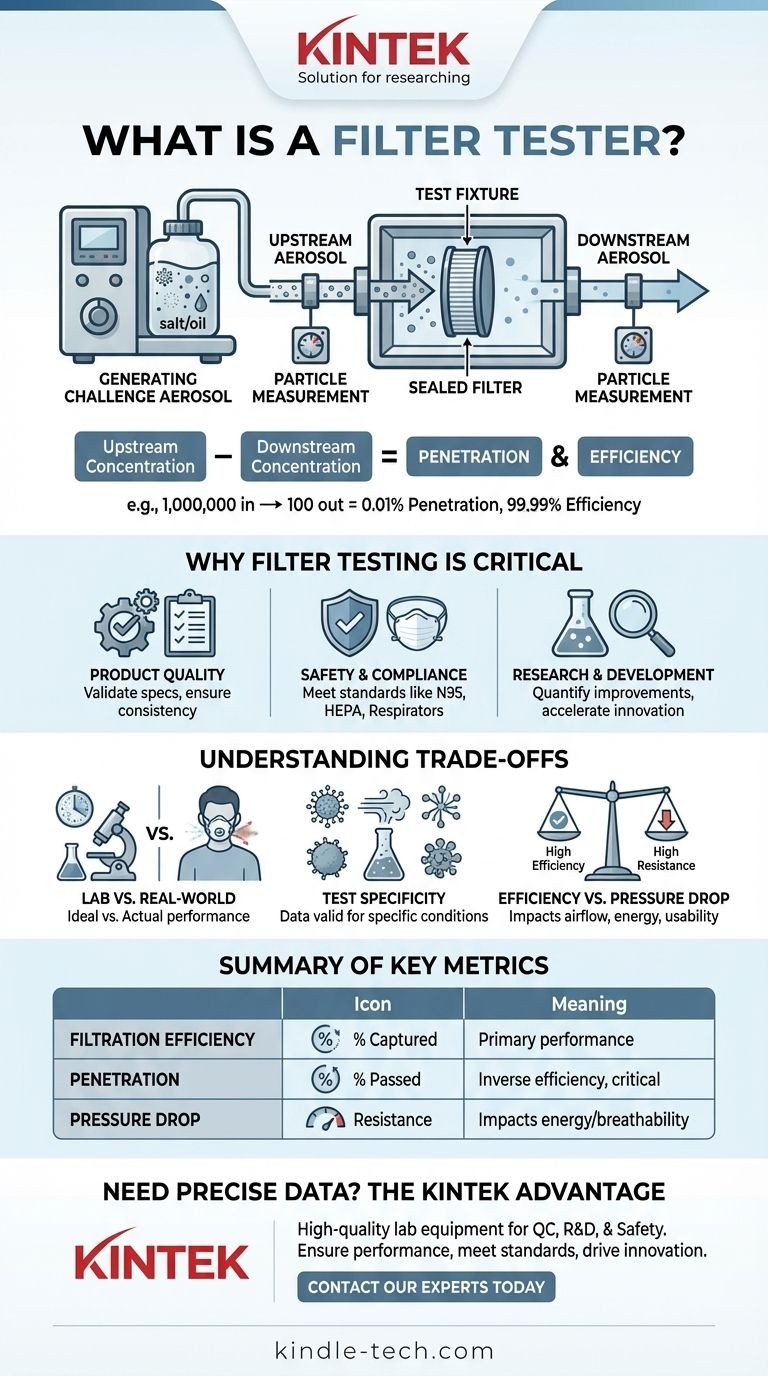

The Fundamental Principle: Challenge and Measurement

Filter testers operate on a simple but powerful "challenge/response" principle. The device creates a worst-case, controlled scenario to see how the filter responds.

Generating the Challenge Aerosol

To test a filter, you need a consistent stream of particles. The tester generates an aerosol—a suspension of fine solid or liquid particles in air—with a known size distribution and concentration. This could be composed of salt (sodium chloride), oil, or other standardized materials.

The Test Fixture

The filter material, whether it's a piece of filter media, a respirator cartridge, or a fully assembled filter, is sealed within a test fixture. A proper seal is critical to ensure that all the aerosolized air is forced to pass through the filter and cannot leak around it.

Upstream and Downstream Measurement

The tester uses photometers or particle counters to measure the aerosol concentration in two key locations:

- Upstream: Before the air enters the filter.

- Downstream: After the air has passed through the filter.

Calculating Efficiency and Penetration

The difference between the upstream and downstream measurements reveals the filter's performance. Penetration is the percentage of particles that successfully passed through the filter. Efficiency is the percentage of particles that were captured.

For example, if 1,000,000 particles enter the filter and only 100 get through, the penetration is 0.01% and the efficiency is 99.99%.

Why Filter Testing is Critical

Testing provides the objective data required for quality, safety, and innovation in any industry that relies on filtration.

Ensuring Product Quality

For manufacturers, testers validate that every filter or batch of filter media coming off the production line meets its advertised specifications. This ensures consistency and reliability for the end-user.

Verifying Safety and Compliance

In regulated fields, testing is non-negotiable. For respiratory masks (like N95s), protective garments, or HEPA filters used in cleanrooms and hospitals, testing provides the proof that a product meets strict government or industry safety standards.

Enabling Research and Development

When developing new filter materials or designs, R&D teams rely on testers to quantify improvements. It allows them to compare different materials and construction methods with hard data, accelerating innovation.

Understanding the Trade-offs and Limitations

While essential, the data from a filter tester must be interpreted with an understanding of its context.

Lab Performance vs. Real-World Use

A filter tester provides a perfect-world result. In reality, factors like an improper seal on a face mask or leaks in an HVAC installation can dramatically reduce the effective filtration. The test measures the media's capability, not necessarily the final system's performance.

Specificity of the Test

A filter's efficiency can vary depending on the type and size of the particles used in the test. A result from a salt aerosol test might differ from an oil aerosol test. The data is only truly valid for the specific conditions under which it was generated.

Efficiency is Not the Only Metric

High efficiency often comes at the cost of high pressure drop, meaning it's harder to push air through the filter. An extremely efficient filter might be useless if it restricts airflow too much for its application (e.g., making it difficult to breathe through a mask).

Making the Right Choice for Your Goal

The importance of a filter tester is defined by your specific objective.

- If your primary focus is manufacturing and quality control: View the tester as your non-negotiable gatekeeper for product consistency and batch validation.

- If your primary focus is research and development: Use the tester as an iterative tool to quantify performance gains in new filter media and designs.

- If your primary focus is safety and compliance: Rely on the tester's data as the definitive proof that your products meet critical regulatory standards for applications like respirators or cleanroom air systems.

Ultimately, a filter tester transforms the abstract concept of "filtration" into a concrete, actionable metric.

Summary Table:

| Key Metric | What It Measures | Why It Matters |

|---|---|---|

| Filtration Efficiency | Percentage of particles captured by the filter. | Indicates the filter's primary performance capability. |

| Penetration | Percentage of particles that pass through the filter. | The inverse of efficiency; critical for high-risk applications. |

| Pressure Drop | Resistance to airflow caused by the filter. | Impacts energy consumption and usability (e.g., breathability). |

Need precise, reliable data for your filtration needs?

KINTEK specializes in high-quality lab equipment and consumables for all your testing requirements. Whether you are in manufacturing, quality control, or R&D, our solutions help you ensure product performance, meet stringent safety standards, and drive innovation.

Contact our experts today to find the perfect testing solution for your laboratory.

Visual Guide

Related Products

- Filter Testing Machine FPV for Dispersion Properties of Polymers and Pigments

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Customizable PEM Electrolysis Cells for Diverse Research Applications

- Electrolytic Electrochemical Cell for Coating Evaluation

- Automatic Laboratory Hydraulic Pellet Press Machine for Lab Use

People Also Ask

- How do you test a lithium battery to see if it's good? A Guide to Measuring Voltage, Capacity & Health

- What is the significance of compression set? Predict Material Failure and Ensure Long-Term Reliability

- How do you test the capacity of a lithium-ion battery? A Guide to Accurate Measurement

- What is the minimum coating thickness? How Steel Thickness Determines Your Galvanizing Needs

- Why is coating thickness important? Achieve Optimal Performance and Cost Control