In short, bio-oil is primarily produced from biomass through a process called fast pyrolysis. This involves rapidly heating organic, non-fossil-based materials like wood, agricultural residues, or algae in the absence of oxygen. The intense heat breaks down the complex organic polymers into a liquid (bio-oil), along with solid (biochar) and gaseous (syngas) co-products.

The central concept to grasp is that bio-oil is a renewable but unrefined liquid created by the thermal decomposition of organic matter. It holds potential as a substitute for fossil fuels but is chemically distinct and requires significant processing, or "upgrading," to be used in modern engines or as a chemical feedstock.

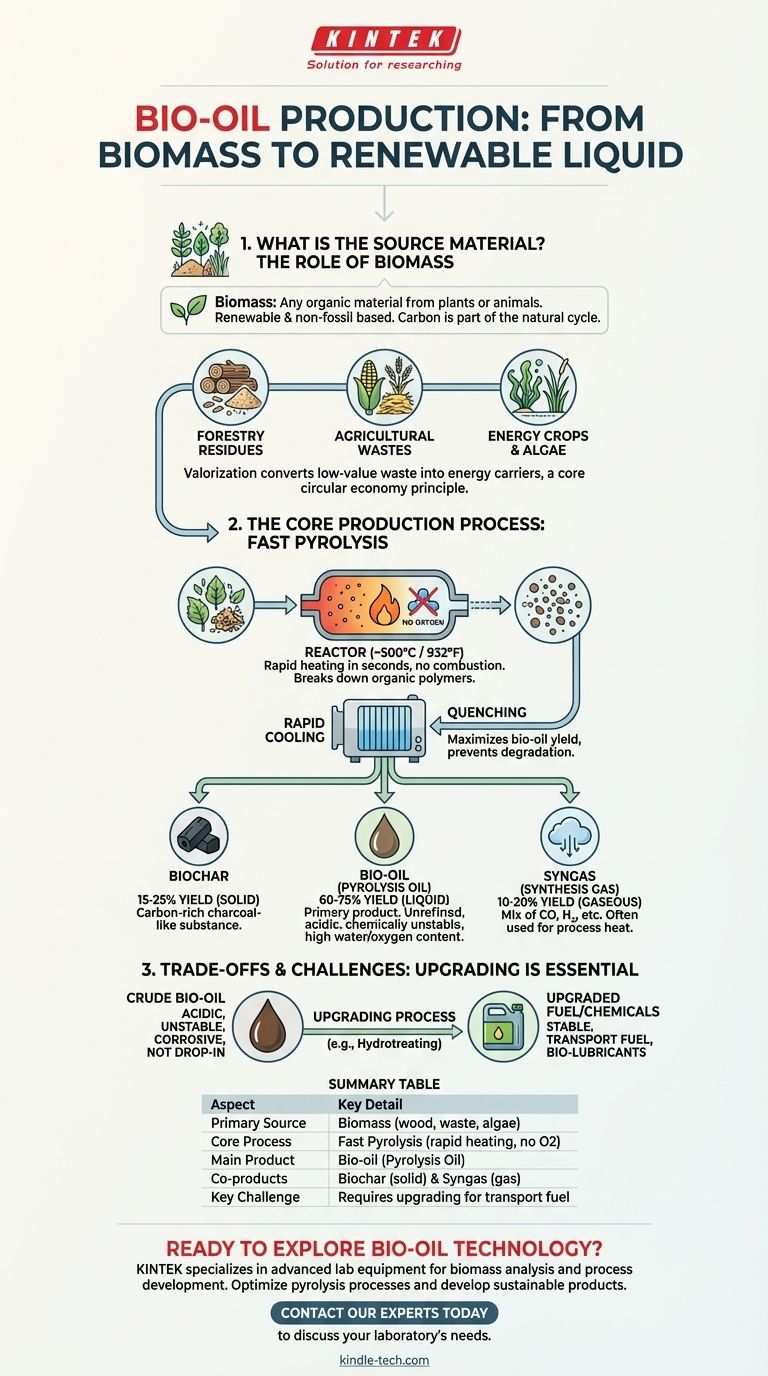

What is the Source Material? The Role of Biomass

Defining Biomass

Biomass is any organic material that comes from plants or animals. In the context of bio-oil production, this specifically refers to non-fossil, renewable resources.

The key characteristic is that the carbon in biomass is part of the natural carbon cycle. This makes it a potential pathway to lower-carbon fuels and chemicals compared to traditional fossil resources.

Common Feedstocks for Production

The most common feedstocks are lignocellulosic materials, which are rich in cellulose, hemicellulose, and lignin.

Examples include forestry residues (wood chips, sawdust), agricultural wastes (corn stover, straw), and dedicated energy crops (switchgrass, miscanthus). Even algae and organic municipal waste can be used.

Why Biomass is the Essential Ingredient

Using biomass converts low-value, often problematic waste streams into a dense, transportable liquid energy carrier. This process, known as valorization, is a core principle of the circular economy.

The Core Production Process: Fast Pyrolysis

Understanding Pyrolysis

Pyrolysis is the thermochemical decomposition of organic material at elevated temperatures in the absence of oxygen. Without oxygen, the material does not combust (burn); it breaks down into smaller molecules.

Think of it as pressure cooking on an extreme scale, where the goal is to break the material down without setting it on fire.

Why "Fast" is Critical

In fast pyrolysis, the biomass is heated to around 500°C (932°F) in just a few seconds. This is followed by rapid cooling, or "quenching."

This speed is crucial. It maximizes the yield of the liquid bio-oil by preventing the molecules from further breaking down into gases or re-polymerizing into solid char.

The Three Main Products

Fast pyrolysis does not create just one output. It yields three distinct products that must be managed:

- Bio-oil (Pyrolysis Oil): The primary liquid product (typically 60-75% of the yield by weight).

- Biochar: A solid, carbon-rich charcoal-like substance (15-25% yield).

- Syngas (Synthesis Gas): A mix of non-condensable gases like carbon monoxide and hydrogen (10-20% yield).

Often, the syngas is combusted on-site to provide the heat needed to run the pyrolysis process, making it more energy-efficient.

Understanding the Trade-offs and Challenges

Bio-oil is Not Crude Oil

It is a common misconception that bio-oil is a direct, "drop-in" replacement for petroleum crude oil. It is not.

Bio-oil is highly acidic, chemically unstable, and contains significant amounts of water (15-30%) and oxygen. These properties make it corrosive to standard pipes and incompatible with conventional refinery equipment.

The Necessity of Upgrading

Before bio-oil can be used as a transportation fuel (like gasoline or diesel) or to create high-value products like biolubricants, it must be upgraded.

Upgrading involves processes like hydrotreating, which uses hydrogen and a catalyst to remove oxygen and stabilize the molecules. This step adds significant cost and complexity to the overall production chain.

Feedstock Logistics

A major operational challenge is the supply chain. Biomass is often bulky, has a low energy density, and is geographically dispersed, making collection and transportation to a central processing facility economically demanding.

Making the Right Choice for Your Goal

Understanding the nature of bio-oil is key to seeing its proper application in different fields.

- If your primary focus is renewable energy generation: Recognize bio-oil as a direct substitute for heating oil in industrial boilers and furnaces, but know it requires significant upgrading for use as a transport fuel.

- If your primary focus is sustainable materials: View bio-oil as a valuable feedstock for producing green chemicals, resins, and advanced bioproducts after the necessary refining and separation steps.

- If your primary focus is waste reduction: See fast pyrolysis as a powerful technology for converting agricultural and forestry waste into a valuable and energy-dense liquid resource.

Bio-oil represents a critical link in converting raw biomass into a versatile platform for renewable energy and sustainable products.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Primary Source | Biomass (wood, agricultural residues, algae) |

| Core Process | Fast Pyrolysis (rapid heating without oxygen) |

| Main Product | Bio-oil (Pyrolysis Oil) |

| Co-products | Biochar (solid) and Syngas (gaseous) |

| Key Challenge | Requires upgrading for use as transport fuel |

Ready to explore how bio-oil technology can fit into your renewable energy or waste valorization strategy? KINTEK specializes in advanced lab equipment and consumables for biomass analysis and process development. Our solutions help researchers and engineers optimize pyrolysis processes and develop sustainable products. Contact our experts today to discuss how we can support your laboratory's specific needs.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What are the components of biomass pyrolysis? A Complete Guide to the System, Products, and Process

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products