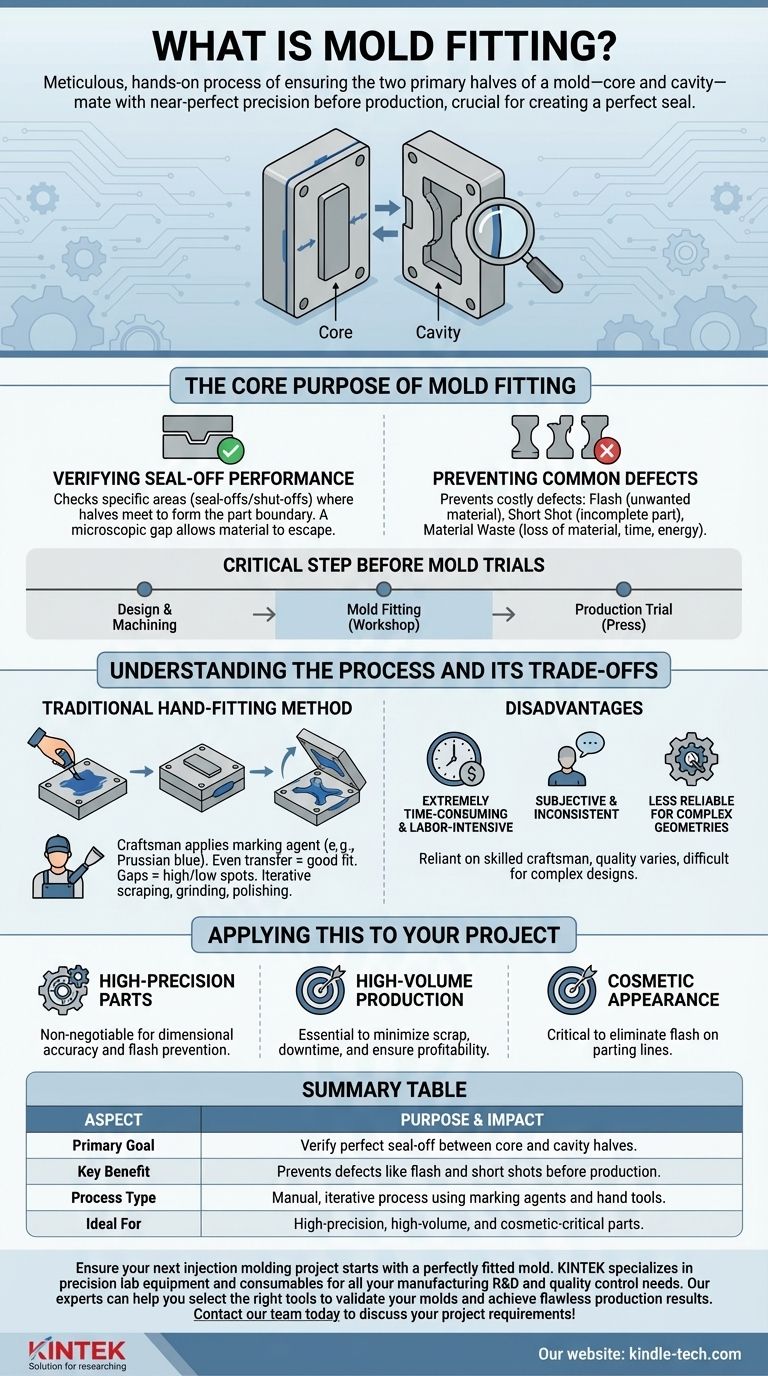

In short, mold fitting is the meticulous, hands-on process of ensuring the two primary halves of a mold—the core and the cavity—mate together with near-perfect precision. This crucial procedure is performed before a full production trial to verify the mold's ability to create a perfect seal, which is essential for containing the molten material during injection.

The core purpose of mold fitting is not just to see if the parts fit, but to function as a critical quality assurance step. It proactively identifies and corrects potential sealing failures to prevent expensive part defects like flash or short shots before the mold ever enters a production environment.

The Core Purpose of Mold Fitting

Mold fitting is a foundational step in the toolmaking process. It serves as the final manual verification that the machined tool will perform as designed under the immense pressures of injection molding.

Verifying the Seal-Off Performance

The primary goal is to check the seal-off (also called "shut-off") surfaces. These are the specific areas where the core and cavity meet to form the boundary of the part.

If these surfaces don't meet perfectly, a gap exists. Even a microscopic gap can allow molten plastic to escape under high pressure.

Preventing Common Molding Defects

A poor fit directly leads to costly and common manufacturing defects.

Proper fitting helps prevent:

- Flash: Thin, unwanted material that escapes the part cavity through gaps in the seal.

- Short Shot: An incomplete part, which can occur if pressure is lost through a poor seal before the cavity is fully filled.

- Material Waste: Flash and rejected parts represent a direct loss of raw material, time, and energy.

A Critical Step Before Mold Trials

Mold fitting is performed before the mold is installed in an injection molding press for a formal trial.

This allows toolmakers to make fine adjustments in a controlled workshop environment, which is far cheaper and faster than discovering a problem during a full-scale, machine-dependent trial.

Understanding the Process and Its Trade-offs

The traditional method of mold fitting relies on the skill of an expert craftsman, but this approach comes with inherent limitations.

The Traditional Hand-Fitting Method

The process is typically done by hand. A craftsman applies a marking agent (like Prussian blue dye) to one half of the mold.

The mold is then carefully closed. When reopened, the transfer of the dye to the other half reveals the high and low spots. An even, consistent transfer indicates a good fit, while gaps in the dye show areas that need adjustment.

The craftsman then meticulously scrapes, grinds, or polishes the high spots to achieve a perfect seal. This is a highly iterative and skill-dependent process.

The Disadvantages of Manual Fitting

While effective, the traditional method has several key disadvantages.

It is extremely time-consuming and labor-intensive, relying entirely on the availability of a skilled toolmaker.

The process is also subjective. The quality of the fit can vary between different craftsmen, leading to potential inconsistencies.

Finally, for molds with highly complex geometries, achieving a perfect fit by hand becomes exponentially more difficult and less reliable. Modern high-precision machining has reduced the need for extensive hand-fitting, but it often remains a final, critical validation step.

Applying This to Your Project

Understanding the role of mold fitting helps you assess the quality and readiness of your production tooling. The level of scrutiny required depends entirely on your project's goals.

- If your primary focus is high-precision parts with tight tolerances: A meticulous and well-documented mold fitting process is non-negotiable to prevent dimensional inaccuracies and flash.

- If your primary focus is high-volume production: Investing time in proper mold fitting up-front is essential to minimize scrap rates, reduce machine downtime, and ensure long-term profitability.

- If your primary focus is cosmetic appearance: Thorough fitting is critical to eliminate flash, which often appears on parting lines and is a common cause of cosmetic rejection.

Ultimately, proper mold fitting is the critical link between a well-designed tool and a flawlessly manufactured part.

Summary Table:

| Aspect | Purpose & Impact |

|---|---|

| Primary Goal | Verify perfect seal-off between core and cavity halves. |

| Key Benefit | Prevents defects like flash and short shots before production. |

| Process Type | Manual, iterative process using marking agents and hand tools. |

| Ideal For | High-precision, high-volume, and cosmetic-critical parts. |

Ensure your next injection molding project starts with a perfectly fitted mold. KINTEK specializes in precision lab equipment and consumables for all your manufacturing R&D and quality control needs. Our experts can help you select the right tools to validate your molds and achieve flawless production results. Contact our team today to discuss your project requirements!

Visual Guide

Related Products

- Isostatic Molding Pressing Molds for Lab

- Three-dimensional electromagnetic sieving instrument

- High Performance Lab Homogenizer for Pharma Cosmetics and Food R&D

- Lab Internal Rubber Mixer Rubber Kneader Machine for Mixing and Kneading

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What are molds used for? Unlock Mass Production of Precision Parts

- What are the two structures of molds? Understanding Hyphae and Mycelium

- What are the different types of compression molds? A Guide to Flash, Positive, Semi-Positive & Landed Positive Molds

- What are the applications of moulding process? Powering Mass Production from Cars to Medical Devices

- What are the different types of molds? A Guide to Choosing the Right Process for Your Product