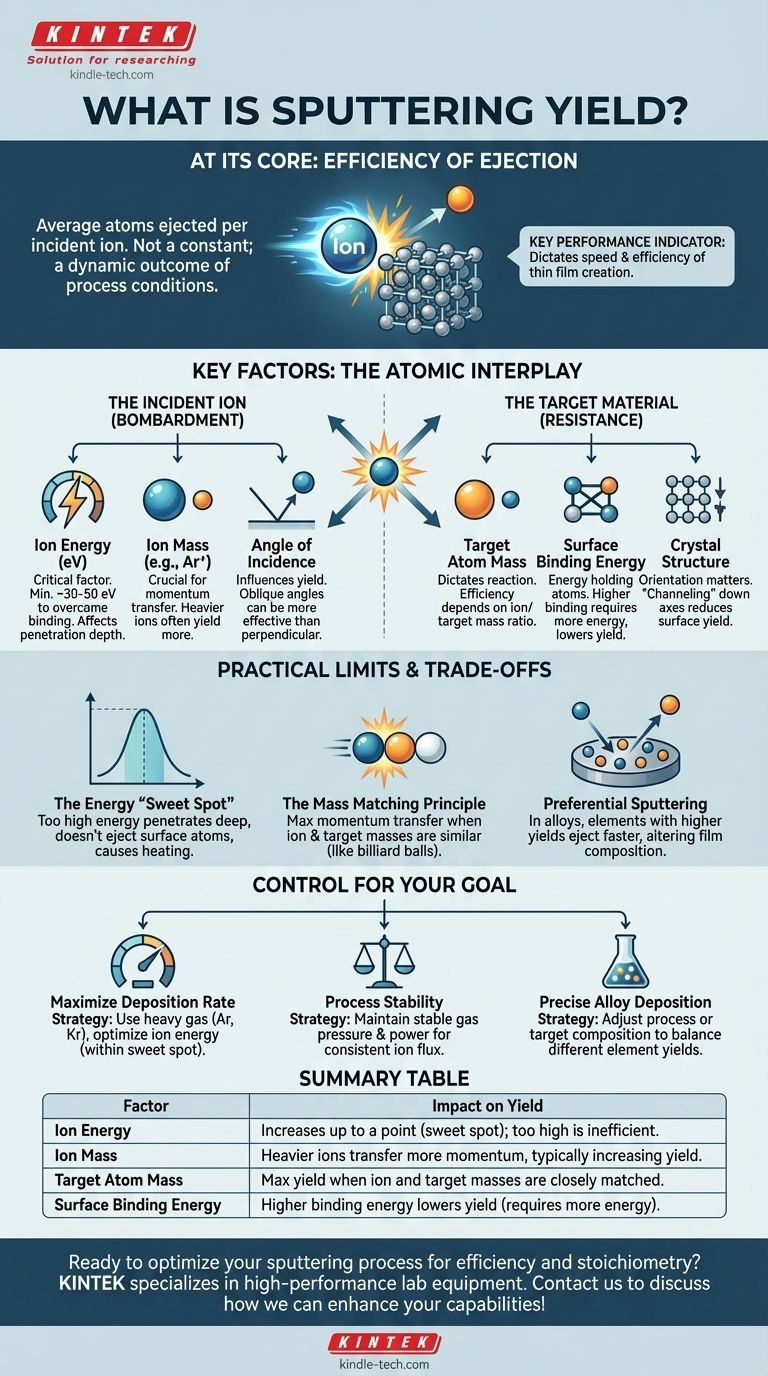

At its core, sputtering yield is the measure of efficiency in a sputtering process. It is defined as the average number of atoms ejected from a target material for each single ion that strikes its surface. This value is not a constant; it is a dynamic outcome dependent on the specific conditions of the process.

Understanding sputtering yield is about understanding the fundamental levers you can pull to control your deposition process. It isn't just a definition to memorize, but a key performance indicator that dictates the speed and efficiency of creating your thin film.

The Key Factors That Define Sputtering Yield

To truly control a sputtering process, you must understand the interplay of forces at the atomic level. The sputtering yield is determined by the physics of the collision between the incoming ion and the atoms of the target material.

The Role of the Incident Ion

The characteristics of the particle you use for bombardment are a primary control mechanism.

Ion Energy: The kinetic energy of the incoming ion is a critical factor. There is a minimum energy, typically between 30-50 eV, required to overcome the target's binding forces and dislodge an atom.

Ion Mass: The mass of the sputtering gas ion (e.g., Argon) plays a crucial role in momentum transfer. A heavier ion can transfer more momentum to a target atom, often resulting in a higher yield.

Angle of Incidence: The angle at which the ion strikes the target surface also influences the yield. An oblique angle can sometimes be more effective at ejecting surface atoms than a direct, perpendicular impact, though this depends heavily on the specific materials and energies involved.

The Properties of the Target Material

The material you are trying to deposit has its own inherent properties that resist the sputtering process.

Target Atom Mass: The mass of the atoms in the target material dictates how they will react to a collision. The efficiency of energy transfer depends on the mass ratio between the incident ion and the target atom.

Surface Binding Energy: This is the energy that holds the atoms together within the target material. A material with a high surface binding energy will require more energy to dislodge an atom, resulting in a lower sputtering yield under the same conditions.

Crystal Structure: For crystalline targets, the orientation of the crystal axes relative to the ion beam is significant. Ions may travel more easily down certain crystalline channels (a phenomenon known as "channeling"), depositing their energy deeper into the target and reducing the surface sputtering yield.

Understanding the Practical Limits and Trade-offs

Simply maximizing every variable does not guarantee the best result. The relationship between these factors is nuanced, and understanding the trade-offs is essential for process control.

The Energy "Sweet Spot"

While a minimum energy is required, simply increasing ion energy indefinitely does not always increase the yield. After a certain point, very high-energy ions penetrate too deeply into the target. They deposit their energy far below the surface, which does not contribute to ejecting surface atoms and can cause unwanted heating or structural damage.

The Mass Matching Principle

Maximum momentum transfer—and thus the highest yield—occurs when the masses of the incident ion and the target atom are closely matched. Think of it like a billiard ball collision. A cue ball (ion) hitting a ball of similar mass (target atom) transfers its energy very efficiently. If the ion is much lighter than the target atom, it may simply bounce off with little effect.

Preferential Sputtering

When sputtering a composite material or alloy, the element with the higher individual sputtering yield will be ejected at a faster rate. This "preferential sputtering" can alter the surface composition of the target and, if not managed, can cause the deposited film's stoichiometry to differ from that of the source target.

How to Control Sputtering Yield for Your Goal

Your ideal sputtering yield depends entirely on your objective. By understanding the core principles, you can adjust your process parameters to achieve a specific outcome.

- If your primary focus is maximizing deposition rate: Use a heavy sputtering gas (like Argon or Krypton) and increase ion energy, but be mindful of operating within the energy sweet spot to avoid deep penetration and inefficiency.

- If your primary focus is process stability: Concentrate on maintaining a highly stable gas pressure and power delivery to the target, as this ensures a consistent ion energy and flux, leading to a predictable and repeatable sputtering yield.

- If your primary focus is depositing a precise alloy: Be aware that the different elements in your target will have unique sputtering yields, and adjust your process or target composition accordingly to achieve the desired stoichiometry in your final film.

By mastering these variables, you can directly control the efficiency and outcome of your sputtering process.

Summary Table:

| Factor | Impact on Sputtering Yield |

|---|---|

| Ion Energy | Increases yield up to a point; too high causes deep penetration and inefficiency. |

| Ion Mass | Heavier ions (e.g., Argon) transfer more momentum, typically increasing yield. |

| Target Atom Mass | Maximum yield occurs when ion and target atom masses are closely matched. |

| Surface Binding Energy | Higher binding energy requires more energy to dislodge atoms, lowering yield. |

Ready to optimize your sputtering process for maximum efficiency and precise film stoichiometry? KINTEK specializes in high-performance lab equipment and consumables for all your deposition needs. Our experts can help you select the right sputtering system and parameters to achieve your specific goals. Contact us today to discuss how we can enhance your laboratory's capabilities!

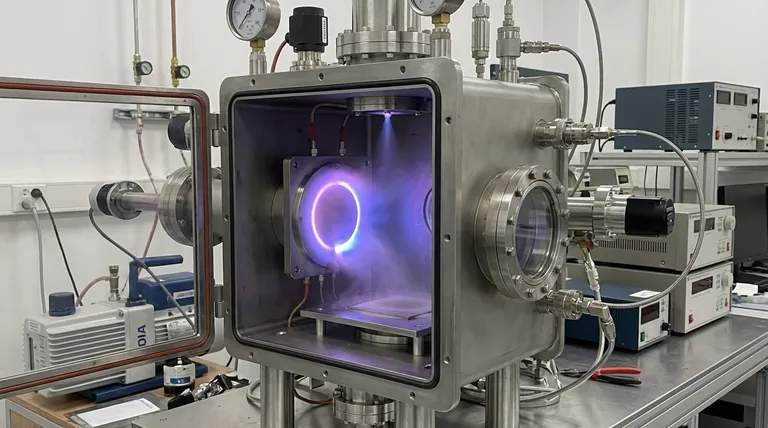

Visual Guide

Related Products

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Vacuum Cold Trap Direct Cold Trap Chiller

People Also Ask

- How does process temperature influence film deposition and what are its limitations? Balancing Quality and Heat Constraints

- What materials are used in thermal evaporation? From Metals to Dielectrics for Thin-Film Coating

- What is evaporation material? The Key to Precision Thin-Film Deposition

- What is the difference between PPF and coating? Armor vs. Slick Shell for Your Car

- How does a molybdenum evaporation source function in H2S for MoS2 synthesis? Master Reactive Film Deposition