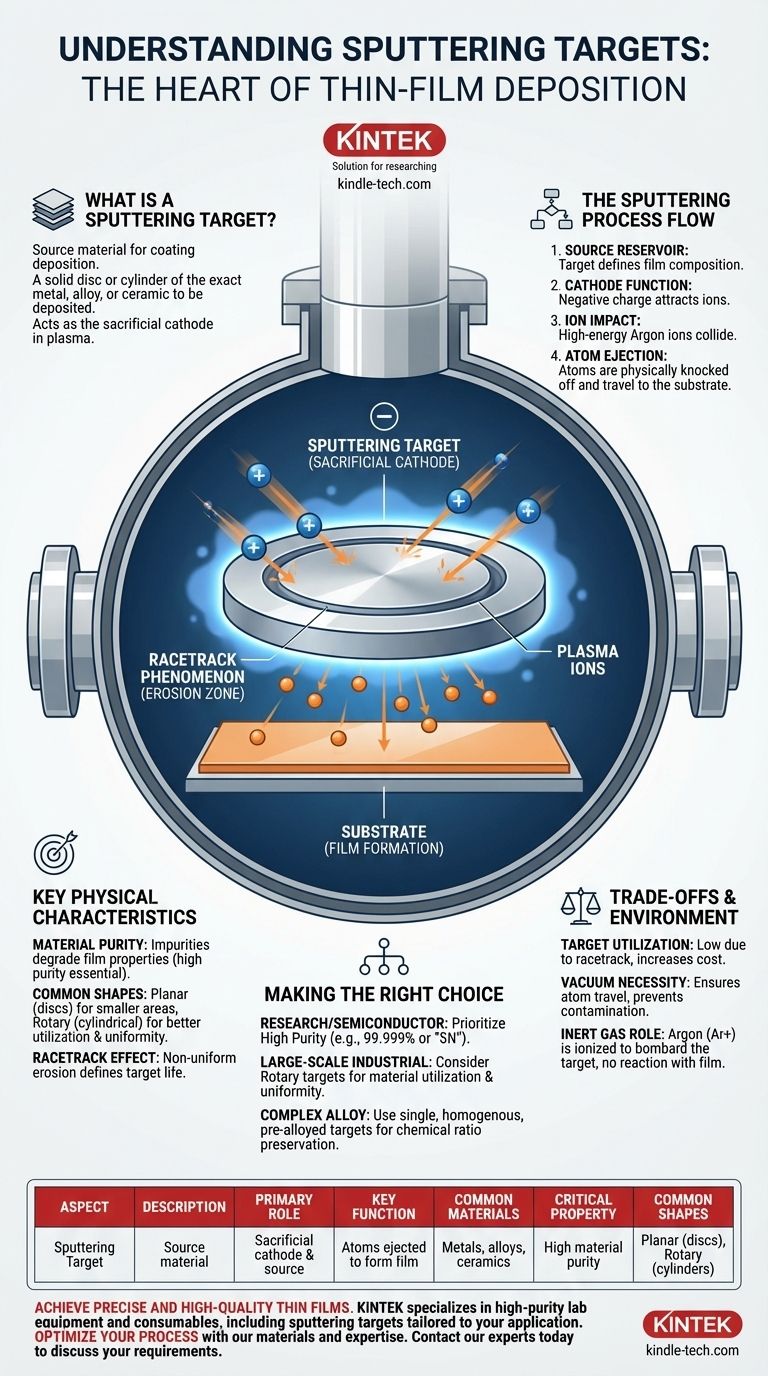

In thin-film deposition, the sputtering target is the source material from which a coating is created. It is a solid piece—often a disc or cylinder—of the exact metal, alloy, or ceramic you intend to deposit onto a substrate. During the sputtering process, this target is bombarded by high-energy ions, which physically knock atoms off its surface, allowing them to travel and form a thin, uniform film on the object being coated.

The sputtering target is more than just a block of raw material; it functions as the sacrificial cathode in a plasma environment. Its composition directly determines the final film's properties, and its interaction with the plasma is the core mechanism of the entire physical vapor deposition (PVD) process.

The Target's Role in the Sputtering Process

To understand the target, you must first understand its central role in the sputtering workflow. The process is a sequence of physical events occurring within a vacuum chamber.

The Source of the Thin Film

The most fundamental role of the target is to be the reservoir of coating material. The composition of the target dictates the composition of the final film. If you need a titanium nitride coating, you will use a titanium target in a nitrogen gas environment.

Functioning as the Cathode

In the sputtering system, the target is not a passive component. It is given a strong negative electrical charge, causing it to function as the cathode. The chamber walls or a separate electrode act as the anode.

The Point of Impact

This negative charge attracts positively charged ions from the plasma. This plasma is typically created by introducing an inert gas, like Argon, and energizing it with a high voltage. The resulting positive Argon ions (Ar+) accelerate directly toward the negatively charged target.

The "Sputtering" Ejection

When these high-energy ions collide with the target, they transfer their momentum and energy to the target's surface atoms. This collision is powerful enough to physically knock out, or "sputter," individual atoms from the target material. These ejected atoms then travel through the vacuum and land on the substrate, building up the desired thin film atom by atom.

Physical Characteristics of a Sputtering Target

The physical nature of the target itself is critical to the success and consistency of the deposition process.

Material Purity and Composition

The purity of the target material is paramount. Any impurities present in the target will be sputtered along with the primary material and incorporated into the thin film, which can degrade its electrical, optical, or mechanical properties. For alloy films, the target must have a uniform, homogenous composition.

Common Shapes and Forms

Targets come in various shapes, but the most common are planar (flat discs) and rotary (cylindrical). The choice depends on the specific equipment and the scale of the operation, with rotary targets often providing better material utilization and uniformity for large-area coating.

The "Racetrack" Phenomenon

Sputtering is rarely uniform across the entire target face, especially when magnets are used to confine the plasma and increase efficiency. The bombardment is most intense in a specific zone, which erodes faster than the rest of the target. This creates a visible groove known as a "racetrack," which defines the usable life of the target.

Understanding the Trade-offs and Environment

The target does not exist in isolation. Its effectiveness is tied directly to its environment and the inherent limitations of the process.

Target Utilization and Cost

Because of the "racetrack" effect, a significant portion of the target material is often left unused when the groove becomes too deep. This low material utilization can increase operational costs, as the entire target must be replaced even though much of it remains.

The Necessity of a Vacuum

The entire process must occur in a high vacuum (typically below 10⁻⁵ mbar). This is necessary for two reasons: first, to ensure the sputtered atoms can travel to the substrate without colliding with air molecules, and second, to prevent contaminants like oxygen or water vapor from being incorporated into the film.

The Role of Inert Gas

After the initial vacuum is achieved, an inert sputtering gas (usually Argon) is introduced at a very low pressure (around 10⁻³ mbar). This gas does not react with the film; its sole purpose is to be ionized to create the plasma "projectiles" that bombard the target.

Making the Right Choice for Your Goal

Selecting the right target and process parameters depends entirely on the desired outcome of your coating.

- If your primary focus is high-purity research or semiconductor fabrication: You must prioritize a target with the highest possible purity (e.g., 99.999% or "5N") to ensure the film's electrical and physical properties are not compromised.

- If your primary focus is large-scale industrial coating (e.g., architectural glass): Consider using rotary targets to maximize material utilization and achieve better uniformity over large areas, reducing long-term operational costs.

- If your primary focus is depositing a complex alloy: Ensure your target is a single, pre-alloyed piece with a homogenous composition to guarantee the resulting film has the same chemical ratio as the source.

Ultimately, understanding the target is the first step toward mastering the control, quality, and efficiency of any sputtering application.

Summary Table:

| Aspect | Description |

|---|---|

| Primary Role | Serves as the sacrificial cathode and source material for the coating. |

| Key Function | Its atoms are ejected by ion bombardment to form a thin film on a substrate. |

| Common Materials | Metals, alloys, and ceramics (e.g., Titanium for TiN coatings). |

| Critical Property | High material purity is essential for the final film's quality. |

| Common Shapes | Planar (discs) and Rotary (cylinders). |

Ready to Achieve Precise and High-Quality Thin Films?

Your sputtering target is the heart of your deposition process. Choosing the right material, purity, and form factor is critical to the success of your research or production.

KINTEK specializes in high-purity lab equipment and consumables, including sputtering targets tailored to your specific application—whether for semiconductor research, industrial coating, or complex alloy deposition. We provide the materials and expertise to ensure your films meet the highest standards for performance and consistency.

Let us help you optimize your process. Contact our experts today to discuss your sputtering target requirements and discover how KINTEK can support your laboratory's goals.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

- Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

People Also Ask

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What are the uses of PECVD? A Guide to Low-Temperature Thin-Film Deposition

- What is plasma activated chemical vapor deposition? Enable Low-Temperature Thin Film Deposition

- What are the disadvantages of plasma enhanced chemical vapor deposition? Managing the Trade-offs of Low-Temperature Deposition

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition