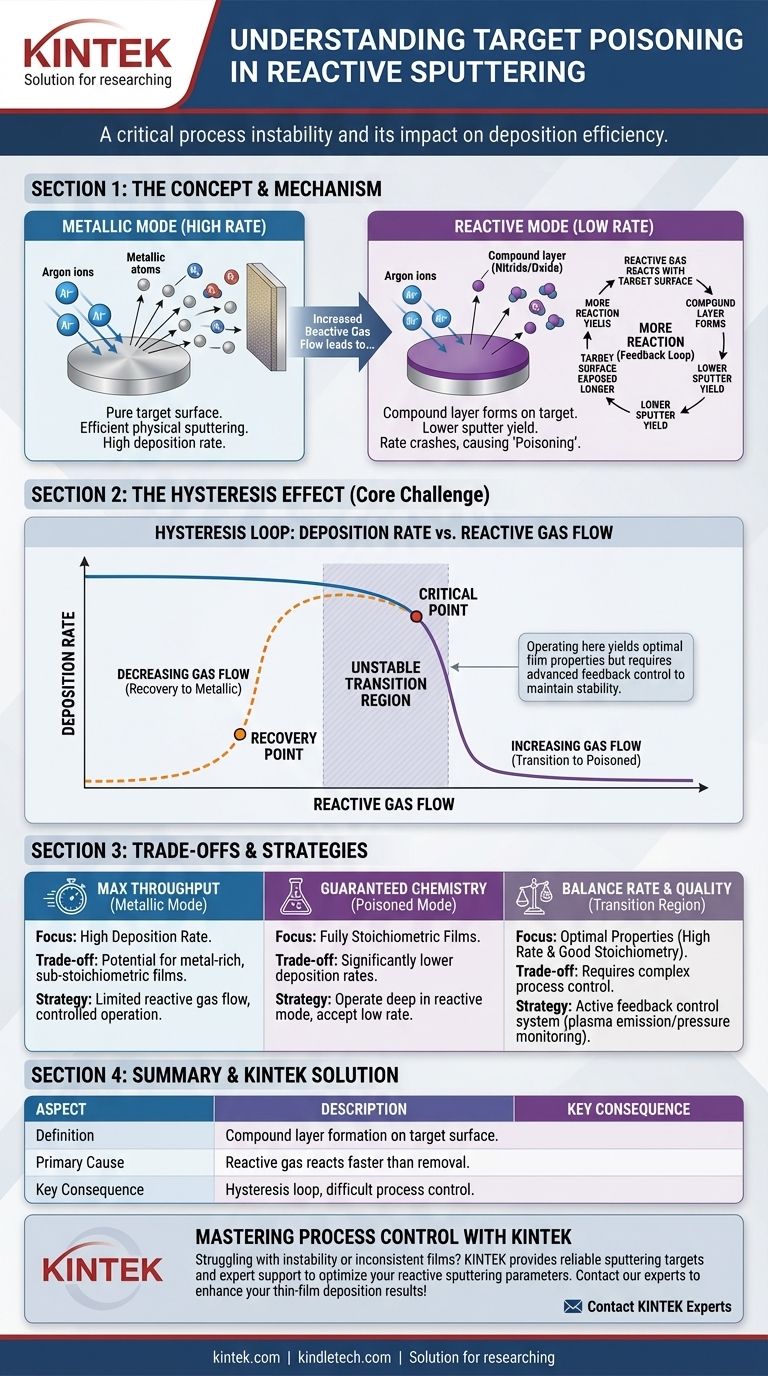

In reactive sputtering, target poisoning is a critical process instability where the surface of the sputtering target chemically reacts with the process gas. This reaction forms a compound layer, such as a nitride or oxide, directly on the target, which has a significantly lower sputter rate than the pure target material, causing a sharp drop in deposition efficiency.

Target poisoning represents a fundamental shift in the process from a high-rate "metallic mode" to a low-rate "reactive mode." This transition is often abrupt and exhibits a hysteresis effect, making it a central challenge in controlling reactive sputtering processes.

The Mechanics of Target Poisoning

To understand poisoning, we must first distinguish between standard and reactive sputtering. This distinction is the key to grasping why the process becomes unstable.

Sputtering in a Non-Reactive Environment

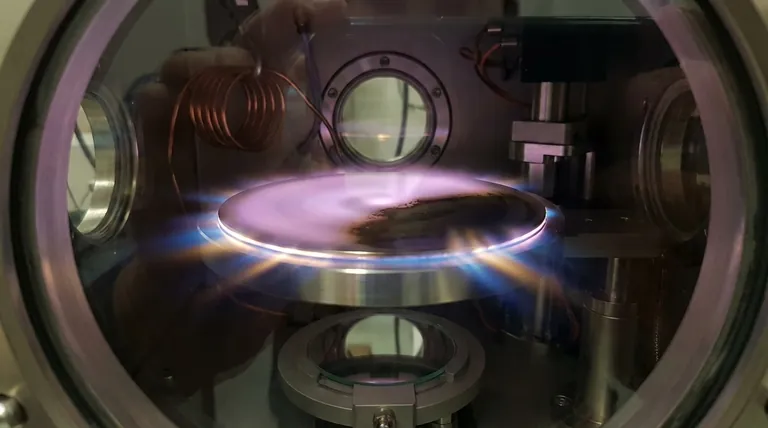

In its simplest form, sputtering involves bombarding a target material with high-energy ions, typically from an inert gas like Argon.

These ions act like a nanoscale sandblaster, physically knocking atoms loose from the target. These ejected atoms then travel and deposit onto a substrate, forming a thin film. This is a purely physical process.

Introducing the Reactive Gas

Reactive sputtering adds a second gas to the chamber, such as nitrogen (N₂) or oxygen (O₂). The goal is for this gas to react with the sputtered atoms on the substrate surface to form a compound film (e.g., titanium nitride or aluminum oxide).

Ideally, this reaction happens primarily on the substrate. However, the reactive gas is present throughout the entire chamber, including around the target.

The Tipping Point: From Reaction to Poisoning

Target poisoning occurs when the reactive gas molecules begin to react with the target surface faster than the sputtering process can remove them.

A compound layer—the very material you want on your film—starts to form on the target itself. For example, in a titanium nitride process, a layer of TiN forms on the pure titanium target.

The Vicious Cycle of a Poisoned Target

This new compound layer has a much lower sputter yield than the pure metal. It is simply harder to knock atoms off a nitride or an oxide than a metal.

This creates a vicious cycle:

- A compound layer forms on the target.

- The sputter rate decreases because the compound is harder to remove.

- Because the sputter rate is lower, the target surface is exposed for longer, allowing even more reactive gas to react with it and thicken the compound layer.

This feedback loop causes a rapid, non-linear collapse of the deposition rate.

The Hysteresis Effect: A Core Challenge

The most problematic consequence of target poisoning is process hysteresis. This phenomenon complicates process control significantly.

Transitioning into the Poisoned Mode

As you slowly increase the reactive gas flow, the deposition rate remains high and stable for a time (the "metallic mode"). Once the gas flow reaches a critical point, the target surface poisons rapidly, and the deposition rate crashes to a new, low-rate steady state (the "reactive mode").

Difficulty in Recovery

To recover, you cannot simply reduce the gas flow back to just below the critical point. Because the poisoned target has a low sputter rate, it cannot "clean itself" effectively.

You must reduce the reactive gas flow to a much lower level to allow the ion bombardment to gradually sputter away the compound layer and return the target to its metallic state.

The Process Control Dilemma

Plotting deposition rate against reactive gas flow reveals this hysteresis loop. The process behaves differently depending on whether you are increasing or decreasing the gas flow. Operating in the unstable transition region between the two modes—often where the best film properties are found—is exceptionally difficult without advanced feedback control.

Understanding the Trade-offs

Managing target poisoning is a balancing act between deposition rate and film quality. There is no single "correct" operating point; the optimal choice depends entirely on your goal.

Film Stoichiometry vs. Rate

To achieve a fully reacted, or stoichiometric, film (e.g., perfect TiN), you often need a high partial pressure of reactive gas. This pushes the process toward the poisoned mode, sacrificing deposition rate for film chemistry.

Process Stability vs. Efficiency

Operating firmly in the metallic mode provides a high, stable deposition rate. However, the resulting films may be sub-stoichiometric or "metal-rich" because there isn't enough reactive gas available at the substrate.

Arcing and Film Defects

The formation of insulating compound layers on the target can lead to charge buildup. This can cause electric arcs, which can damage the power supply and eject macro-particles ("spits") that create defects in the growing film.

Making the Right Choice for Your Goal

Controlling target poisoning requires a clear understanding of your process priorities. There are three primary strategies for managing the reactive sputtering process.

- If your primary focus is maximum throughput and rate: Operate in the metallic mode with a carefully controlled, limited flow of reactive gas, but be prepared for potentially metal-rich films.

- If your primary focus is guaranteed film chemistry: Operate deep in the poisoned (reactive) mode, accepting the significantly lower deposition rates as a necessary trade-off for fully stoichiometric films.

- If your primary focus is balancing rate and quality: Implement an active feedback control system (monitoring plasma emission or partial pressure) to operate within the unstable transition region, which is the only way to achieve both high rates and good stoichiometry.

Mastering reactive sputtering is not about avoiding poisoning, but about understanding and controlling it to achieve your specific film properties.

Summary Table:

| Aspect | Description |

|---|---|

| Definition | Formation of a compound layer (e.g., nitride, oxide) on the target surface, drastically reducing sputter rate. |

| Primary Cause | Reactive gas (e.g., O₂, N₂) reacts with the target surface faster than the sputtering process can remove it. |

| Key Consequence | Hysteresis effect: a sharp, non-linear drop in deposition rate that is difficult to reverse. |

| Process Modes | Metallic Mode: High deposition rate, potential for metal-rich films. Reactive Mode: Low deposition rate, fully stoichiometric films. |

| Control Goal | Balance deposition rate and film stoichiometry based on application requirements. |

Struggling with deposition rate instability or inconsistent film quality in your reactive sputtering processes? KINTEK specializes in lab equipment and consumables, providing the reliable sputtering targets and expert support you need to master process control. Our team can help you select the right materials and optimize your parameters to mitigate target poisoning and achieve your desired film properties. Contact our experts today to discuss your specific laboratory needs and enhance your thin-film deposition results!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Vacuum Cold Trap Direct Cold Trap Chiller

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition