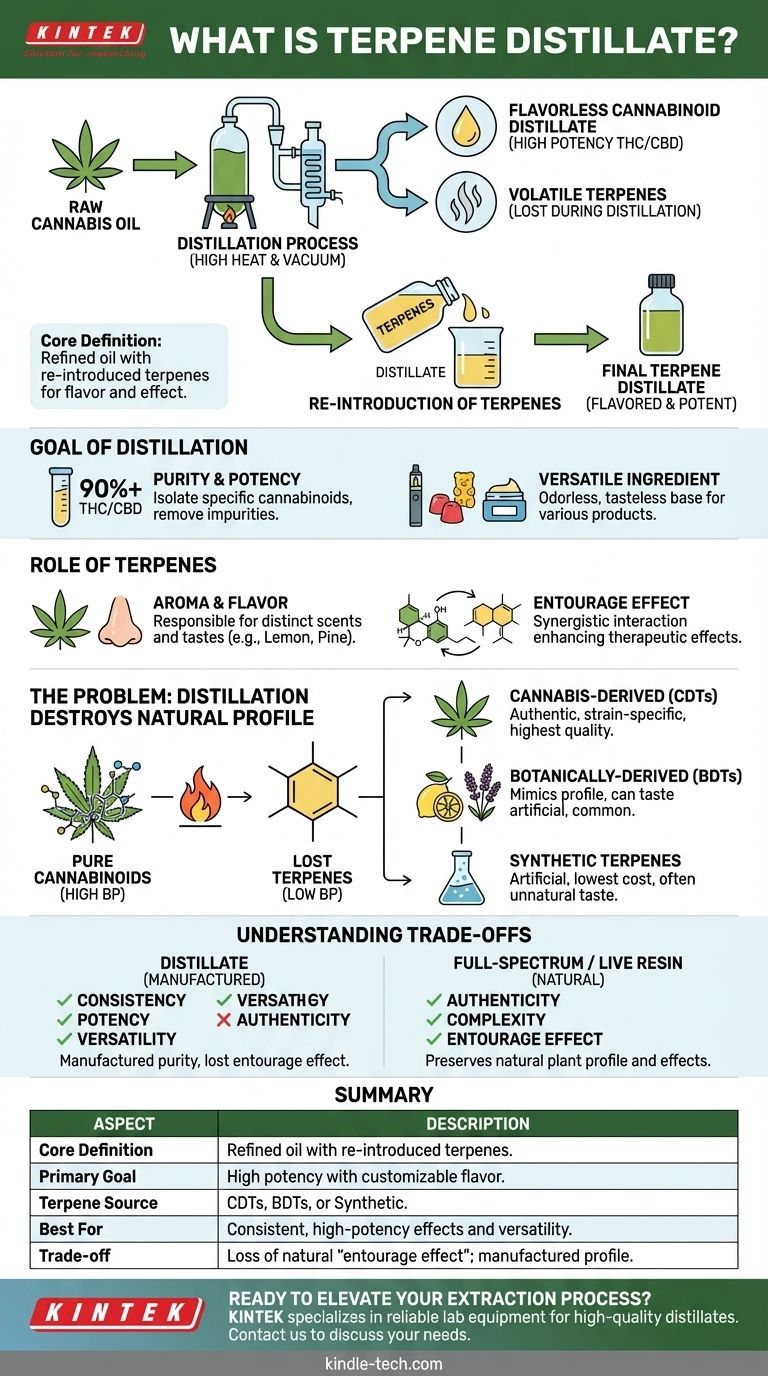

At its core, a "terpene distillate" is a highly refined cannabis or hemp oil where terpenes have been re-introduced after the initial extraction process. The term itself can be misleading; the process of creating distillate actually removes the natural terpenes, resulting in a potent but flavorless cannabinoid oil. Terpenes are then added back to create the final, flavored product you find on the market.

The central concept to grasp is that distillate prioritizes high cannabinoid potency (like THC or CBD) above all else. This purity comes at the cost of the plant's original aromatic and flavor profile, which manufacturers attempt to reconstruct by adding terpenes back into the finished oil.

What Is the Goal of Distillation?

The Pursuit of Purity and Potency

The primary purpose of distillation in cannabis processing is to isolate specific cannabinoids. The process separates compounds based on their unique boiling points, allowing manufacturers to create an oil that is incredibly potent, often testing above 90% THC or CBD.

This resulting oil, known as distillate, is a thick, translucent liquid that is free from waxes, fats, and other plant matter. It is also odorless and tasteless because the heat-sensitive compounds that create aroma and flavor have been removed.

Creating a Versatile Ingredient

This neutral, high-potency oil is extremely versatile. Because it lacks a distinct cannabis flavor or smell, producers can use it as a base ingredient for a wide range of products, including edibles, topicals, and vape cartridges, without imparting a "weedy" taste.

Understanding the Role of Terpenes

The Source of Aroma and Flavor

Terpenes are volatile aromatic compounds found in cannabis and many other plants, like pine trees, lavender, and citrus fruits. They are responsible for the distinct scent and flavor profiles of different cannabis strains—the difference between a lemony "Super Lemon Haze" and an earthy "OG Kush" is due to their unique terpene profiles.

The "Entourage Effect"

Beyond flavor, many believe terpenes play a crucial role in the overall experience through a synergistic phenomenon called the entourage effect. This theory suggests that terpenes work together with cannabinoids like THC and CBD to modulate and enhance their effects, creating a more nuanced and holistic outcome than a cannabinoid alone could provide.

The Problem: Distillation Destroys the Natural Profile

How Heat Separates the Components

The short-path distillation process uses high heat and vacuum pressure to separate molecules. Terpenes are highly volatile and have low boiling points, so they evaporate first. Cannabinoids like THC and CBD have much higher boiling points, so they are separated later in the process.

This fundamental difference in boiling points means the original, naturally occurring terpene profile of the plant is effectively stripped away and lost. The result is pure cannabinoid oil, but the soul of the specific strain is gone.

Rebuilding the Experience: Adding Terpenes Back

To make the final product palatable and marketable, producers must re-introduce terpenes to the flavorless distillate. This is where the quality and user experience can vary dramatically. The source of these added terpenes is a critical factor.

- Cannabis-Derived Terpenes (CDTs): These are terpenes extracted directly from cannabis plants. They provide the most authentic and strain-specific flavor and aroma. This is the highest-quality option.

- Botanically-Derived Terpenes (BDTs): These are terpenes extracted from other plants (lemons, pine, etc.) and blended to mimic the profile of a cannabis strain. They are cheaper and more common but can sometimes taste artificial or generic.

- Synthetic Terpenes: These are artificial flavorings created in a lab. They are the lowest-cost and lowest-quality option, often resulting in a candy-like, unnatural taste.

Understanding the Trade-offs

The Upside of Distillate

The primary benefit of distillate is consistency and potency. You get a reliable, powerful dose of a specific cannabinoid. Its neutrality also makes it an ideal, cost-effective base for infused products where a strong cannabis flavor is undesirable.

The Downside of Distillate

The major drawback is the loss of authenticity. You are not consuming an oil that represents the plant in its natural state. The "entourage effect" from the original strain is gone, replaced by a manufactured approximation that may not provide the same nuanced effects as a full-spectrum product.

For vape users, the difference is often immediately noticeable. A distillate cart with BDTs may have a strong, one-dimensional flavor, whereas a product that preserves the original terpenes (like live resin) offers a more complex, layered, and "true-to-plant" experience.

Making the Right Choice for Your Goal

When choosing a cannabis product, understanding the difference between distillate and other extracts allows you to align your purchase with your desired experience.

- If your primary focus is high potency and versatility: A distillate-based product offers a powerful and affordable way to consume cannabinoids, especially in edibles or tinctures.

- If your primary focus is an authentic flavor and effect: Seek out "live resin" or "full-spectrum" extracts, which are processed to preserve the plant's original terpene and cannabinoid profile.

- If you choose a distillate vape and value taste: Look for products that explicitly state they use Cannabis-Derived Terpenes (CDTs) for a more genuine experience.

Ultimately, choosing the right extract is about deciding whether you prefer the manufactured purity of distillate or the natural complexity of the original plant.

Summary Table:

| Aspect | Description |

|---|---|

| Core Definition | A refined cannabis oil where terpenes are re-introduced after initial extraction. |

| Primary Goal | To achieve high cannabinoid potency (often >90% THC/CBD) with a customizable flavor profile. |

| Terpene Source | Can be Cannabis-Derived (CDTs), Botanically-Derived (BDTs), or synthetic. |

| Best For | Users seeking consistent, high-potency effects and versatility in products like edibles or vapes. |

| Trade-off | Loss of the plant's original "entourage effect"; flavor and effects are manufactured. |

Ready to Elevate Your Extraction Process?

Creating high-quality, consistent terpene distillates requires precision equipment. KINTEK specializes in providing reliable lab equipment for the cannabis industry, from extraction systems to distillation setups.

We help producers like you achieve the purity and potency your customers demand. Contact us today to find the right solution for your lab's needs and let's discuss how we can support your production goals.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- Is plastic pyrolysis harmful? The Hidden Dangers of Plastic Waste Conversion

- How are incubators heated? Master Temperature Control for Your Lab's Success

- What are the different types of heat treatment furnaces? Choose the Right Furnace for Your Material's Success

- What controls melting point? The Hierarchy of Forces from Ionic Bonds to Intermolecular Attractions

- What is a rotavap used for? Achieve Fast, Gentle Solvent Evaporation for Your Lab

- How does temperature affect biomass pyrolysis? Master the Key to Biochar, Bio-Oil, and Syngas Yields

- What is the use of oil sludge? Turn Hazardous Waste into Energy & Construction Materials

- What are drawbacks of XRF technique? Key Limitations and Trade-offs to Consider