The primary advantage of a rotary pump is its ability to move a fixed amount of fluid with each revolution, regardless of the discharge pressure. This positive displacement mechanism makes it exceptionally effective at handling high-viscosity fluids, generating high pressures at low flow rates, and creating a strong vacuum—tasks where centrifugal pumps typically struggle.

The choice between a rotary and a centrifugal pump is not about which is superior, but about matching the pump's core operating principle to your specific application. Rotary pumps excel in precision and high-pressure tasks, while centrifugal pumps are built for high-volume, low-pressure transfer.

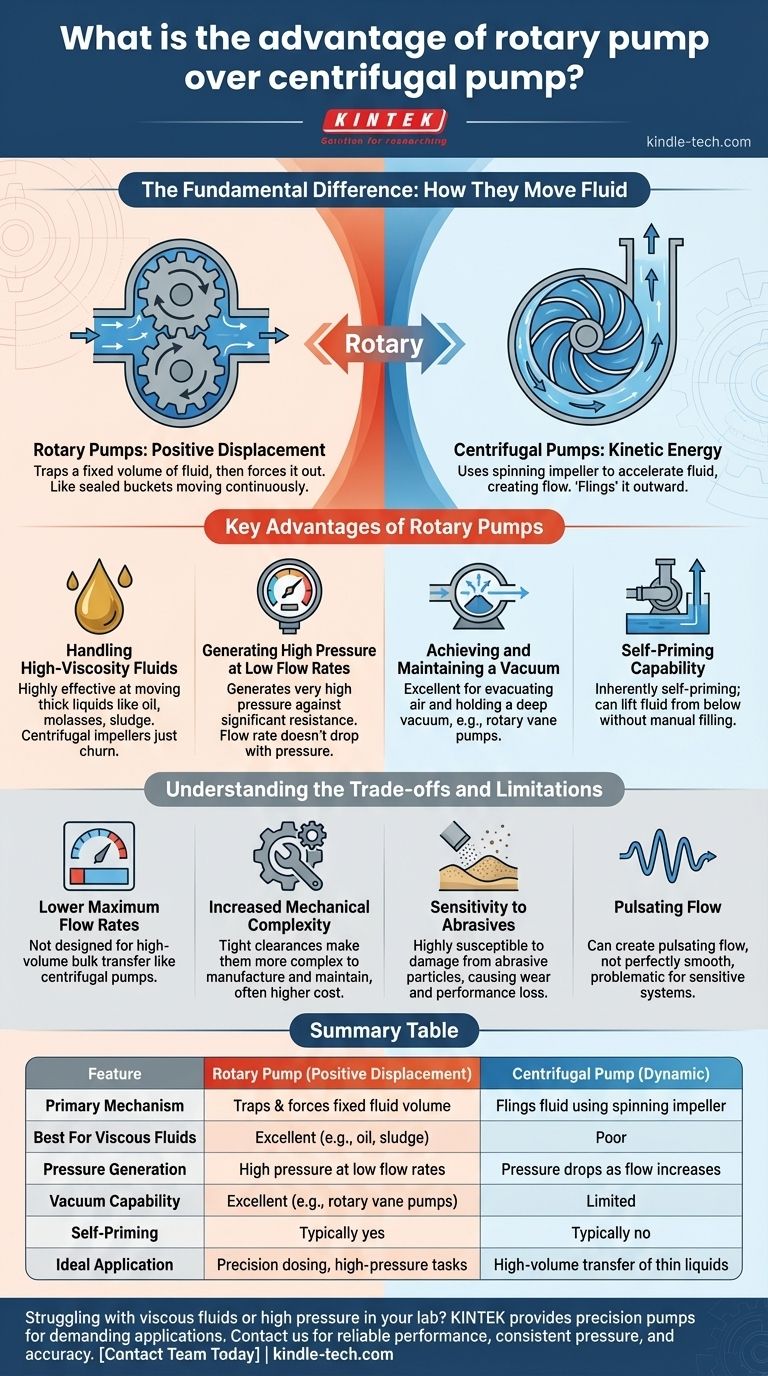

The Fundamental Difference: How They Move Fluid

To understand their advantages, you must first grasp the core mechanical difference between these two pump families. They operate on entirely different principles.

Rotary Pumps: Positive Displacement

A rotary pump is a positive displacement pump. It traps a fixed volume of fluid between its rotating elements (such as gears, lobes, or vanes) and a stationary casing, then forces that trapped volume out the discharge port.

Think of it like a series of small, sealed buckets continuously moving fluid from the inlet to the outlet. This mechanism is what gives it its unique characteristics.

Centrifugal Pumps: Kinetic Energy

A centrifugal pump is a dynamic pump. It uses a spinning impeller to accelerate the fluid, converting rotational kinetic energy into the potential energy of fluid flow.

It doesn't trap fluid. Instead, it "flings" it outward, creating flow. The amount of fluid it moves is highly dependent on the system's back-pressure.

Key Advantages of Rotary Pumps

The positive displacement principle gives rotary pumps a distinct set of advantages in specific scenarios.

Handling High-Viscosity Fluids

Because rotary pumps physically push trapped pockets of fluid, they are highly effective at moving thick, viscous liquids like oil, molasses, or sludge. A centrifugal pump's impeller would simply churn in such a fluid with very little effect.

Generating High Pressure at Low Flow Rates

Rotary pumps can generate very high pressures because the fluid has no path to slip backward. As long as the motor has enough power, the pump will continue to move its fixed volume against significant resistance. Centrifugal pumps see their flow rate drop dramatically as pressure increases.

Achieving and Maintaining a Vacuum

Certain types of rotary pumps, like the rotary vane vacuum pump, are specifically designed to seal exceptionally well. This allows them to effectively evacuate air from a closed system, making them ideal for creating and holding a deep vacuum.

Self-Priming Capability

Many rotary pump designs are inherently self-priming. They can pump air, allowing them to evacuate the suction line and lift fluid from a level below the pump without needing to be manually filled with liquid first. Most standard centrifugal pumps cannot do this.

Understanding the Trade-offs and Limitations

To make an informed decision, it's critical to recognize where rotary pumps are not the best choice. Their advantages come with specific trade-offs.

Lower Maximum Flow Rates

Compared to a centrifugal pump of a similar size and power, a rotary pump will generally have a much lower maximum flow rate. They are not designed for high-volume bulk transfer in the way centrifugal pumps are.

Increased Mechanical Complexity

Rotary pumps operate with very tight internal clearances between the rotating elements and the casing. This precision makes them more complex to manufacture and maintain, often resulting in a higher initial cost.

Sensitivity to Abrasives

Those same tight clearances make rotary pumps highly susceptible to damage from abrasive particles or solids in the fluid. Hard particles can quickly wear down the internal components, causing a loss of performance.

Pulsating Flow

The nature of trapping and discharging discrete volumes of fluid can create a pulsating, rather than perfectly smooth, flow. While often minor, this can be a problem in systems that are sensitive to pressure variations.

Making the Right Choice for Your Application

Selecting the correct pump is about matching the tool to the objective. Consider your primary goal to make a clear decision.

- If your primary focus is high-volume transfer of low-viscosity fluids (like water): A centrifugal pump is almost always the more efficient and cost-effective choice.

- If your primary focus is moving viscous fluids (like oil, syrup, or sludge): A rotary pump is the definitive solution, as a centrifugal pump would be ineffective.

- If your primary focus is creating high pressure at a controlled flow rate or a vacuum: A rotary pump is specifically designed for these high-performance applications.

- If your primary focus is precise metering or dosing: The positive displacement nature of a rotary pump makes it ideal for delivering a consistent, predictable volume with each revolution.

Ultimately, understanding the core mechanism of each pump empowers you to select the right tool for the job, ensuring efficiency and reliability for your system.

Summary Table:

| Feature | Rotary Pump (Positive Displacement) | Centrifugal Pump (Dynamic) |

|---|---|---|

| Primary Mechanism | Traps and forces a fixed volume of fluid | Flings fluid using a spinning impeller |

| Best For Viscous Fluids | Excellent (e.g., oil, sludge) | Poor |

| Pressure Generation | High pressure at low flow rates | Pressure drops as flow increases |

| Vacuum Capability | Excellent (e.g., rotary vane pumps) | Limited |

| Self-Priming | Typically yes | Typically no |

| Ideal Application | Precision dosing, high-pressure tasks | High-volume transfer of thin liquids |

Struggling to move viscous fluids or generate high pressure in your lab?

You've just learned that a rotary pump is the definitive solution for these challenges. At KINTEK, we specialize in providing reliable laboratory equipment, including precision pumps tailored for demanding applications.

Let us help you select the perfect pump for your specific needs. Our experts will ensure you get a solution that delivers:

- Reliable performance with high-viscosity fluids like oils and chemicals.

- Consistent pressure for critical processes.

- Durability and precision for accurate metering and dosing.

Don't let the wrong pump slow down your research or production. Contact our team today for a personalized consultation and discover the KINTEK difference in lab equipment performance.

Visual Guide

Related Products

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Variable Speed Peristaltic Pump

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

People Also Ask

- What are the limitations of rotary vane pumps? Understanding Oil Dependence and Gas Compatibility

- Why is a gas ballast valve necessary on a rotary vane vacuum pump? Protect Your Oil and Extend Pump Life

- What is the primary use of a Rotary Vane Vacuum Pump? Expert Guide to Gas Evacuation and Rough Vacuum Ranges

- Why is a rotary vane mechanical vacuum pump necessary for sub-surface etching? Ensure Precision in ALD/ALE Experiments

- What are the fundamental differences between low-cost and high-end industrial rotary vane vacuum pumps? | KINTEK