There is no single design pressure for a stainless steel (SS) reactor. The design pressure is not a property of the material but is a critical specification determined entirely by the chemical process the reactor is built to contain. It is a custom value calculated based on the maximum pressure expected during operation, including potential upset conditions, plus a mandatory safety margin.

The core takeaway is that you do not look up a reactor's design pressure; you define it. It is a bespoke engineering requirement dictated by the specific reaction's operating pressure, potential for pressure spikes, and governing safety codes.

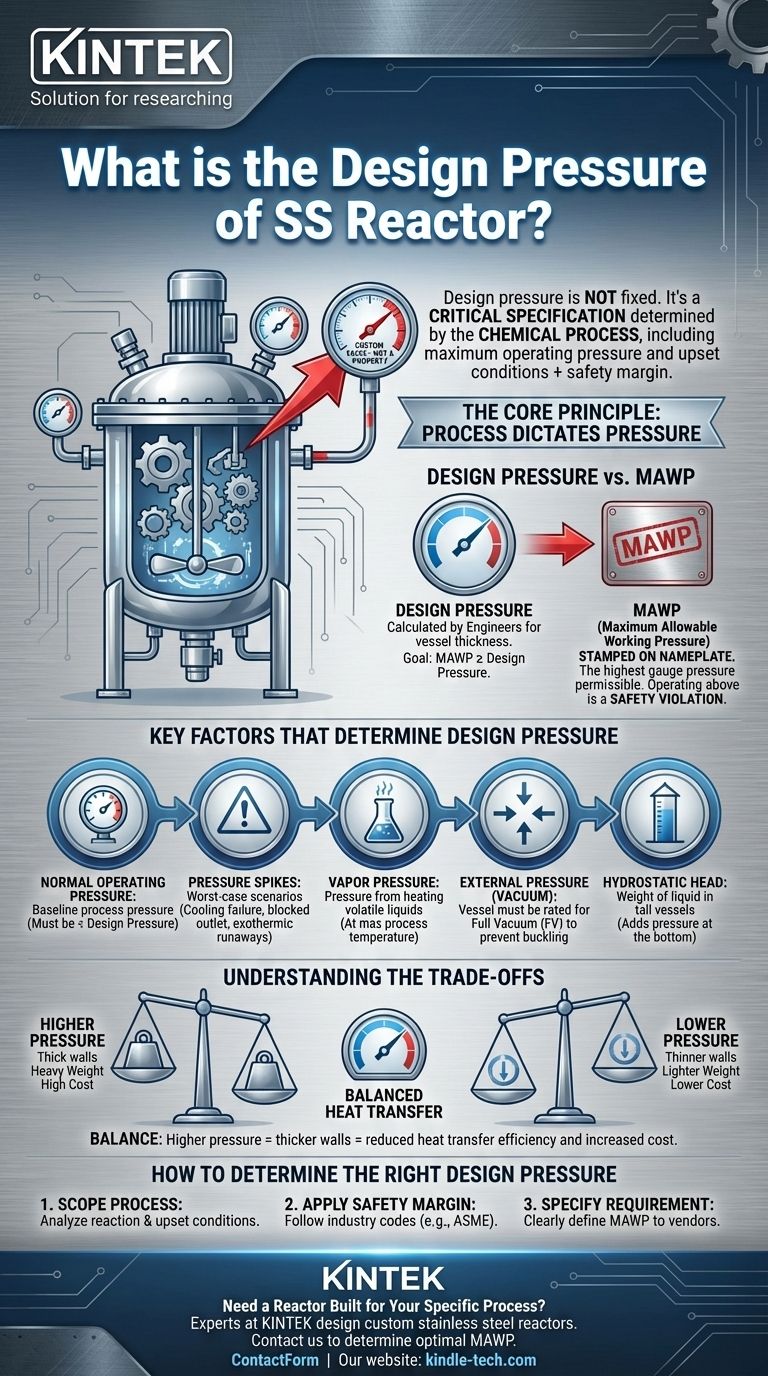

The Core Principle: Process Dictates Pressure

The fundamental concept to grasp is that a reactor is designed and built for a process, not the other way around. The stainless steel is simply the material of construction chosen for its corrosion resistance and strength.

Defining Maximum Allowable Working Pressure (MAWP)

The most important value, which is physically stamped on the vessel's nameplate, is the Maximum Allowable Working Pressure (MAWP). This is the highest gauge pressure permissible at the top of the vessel in its normal operating position at a designated temperature.

The vessel is physically built to withstand this pressure. Operating above the MAWP is a safety violation and risks catastrophic failure.

How Design Pressure Relates to MAWP

Design Pressure is the pressure value used by engineers to perform the calculations for the vessel's thickness and component ratings. The goal is to design a vessel where the resulting MAWP is equal to or, more commonly, slightly greater than the specified design pressure.

For practical purposes in initial discussions, the terms are often used interchangeably, but the MAWP is the final, legally binding limit for the finished equipment.

The Role of the Process Engineer

The responsibility for defining the required design pressure rests with the process engineer or chemist, not the vessel fabricator. They must analyze the process and provide this critical parameter as part of the equipment specification.

Key Factors That Determine Design Pressure

To specify the design pressure, you must analyze every source of pressure the process can generate.

Normal Operating Pressure

This is the baseline pressure at which your chemical reaction or process runs under normal, stable conditions. The design pressure must always be higher than this value.

Potential for Pressure Spikes

This is the most critical factor for safety. You must account for worst-case scenarios, such as a cooling failure in an exothermic reaction, a blocked outlet, or an unintended side reaction that generates gas. The design pressure must safely contain these upsets.

Vapor Pressure of Contents

If you are heating volatile liquids, their vapor pressure will increase significantly with temperature. The design pressure must be high enough to contain the contents at the maximum process temperature without venting.

External Pressure (Vacuum)

If the reactor will be operated under vacuum or could be exposed to a vacuum during steam-out cleaning or cooling, it must also have an external pressure rating. This prevents the vessel from buckling inward. A "Full Vacuum" (FV) rating is common.

Hydrostatic Head

For very tall reactors, the weight of the liquid inside creates additional pressure at the bottom of the vessel. This "hydrostatic head" must be added to the other pressure calculations to ensure the bottom section is sufficiently robust.

Understanding the Trade-offs

Simply choosing an extremely high design pressure is not a viable strategy. There are significant engineering and financial consequences to consider.

Cost vs. Safety

This is the primary trade-off. A higher design pressure requires thicker vessel walls and flanges. This dramatically increases the amount of stainless steel needed, which directly drives up the material cost, fabrication labor, and overall price of the reactor.

Material Thickness and Weight

A higher pressure rating results in a much heavier vessel. This has cascading effects, requiring stronger support structures, a more robust foundation, and more powerful lifting equipment for installation and maintenance.

Heat Transfer Implications

Thicker vessel walls act as an insulator. This can significantly impede heat transfer through the reactor jacket, making it more difficult to control the temperature of an exothermic or endothermic reaction.

How to Determine the Right Design Pressure

To define the appropriate design pressure, you must shift your focus from the vessel itself to the process it will contain.

- If your primary focus is scoping a new process: Analyze your reaction to determine the maximum normal operating pressure and any potential upset conditions. Apply a safety margin based on industry codes (e.g., ASME) to arrive at your required design pressure.

- If your primary focus is purchasing a standard reactor: Clearly specify your required design pressure (e.g., "150 psig and Full Vacuum at 350°F") to vendors. Ensure the MAWP on the quoted equipment meets or exceeds your requirement.

- If your primary focus is evaluating an existing system: Locate the metal nameplate on the reactor. The stamped MAWP is the definitive pressure limit you must never exceed.

Ultimately, the correct design pressure is the one that safely and reliably contains your specific process under all foreseeable conditions.

Summary Table:

| Key Factor | Description | Impact on Design Pressure |

|---|---|---|

| Normal Operating Pressure | Baseline pressure during stable process conditions. | Must be lower than the design pressure. |

| Potential for Pressure Spikes | Worst-case scenarios like cooling failure or blocked outlet. | Design pressure must safely contain these upsets. |

| Vapor Pressure of Contents | Pressure from heated volatile liquids. | Must be accounted for at maximum process temperature. |

| External Pressure (Vacuum) | Required if operating under or exposed to vacuum. | Vessel must be rated for full vacuum (FV) to prevent buckling. |

| Hydrostatic Head | Pressure from the weight of liquid in tall vessels. | Adds to the pressure calculation at the bottom of the vessel. |

Need a Reactor Built for Your Specific Process?

Specifying the correct design pressure is critical for safety, performance, and cost-efficiency. The experts at KINTEK specialize in designing and manufacturing custom stainless steel reactors tailored to your exact chemical process requirements. We work with you to determine the optimal MAWP (Maximum Allowable Working Pressure), ensuring your equipment is safe, reliable, and cost-effective.

Contact us today to discuss your project and get a quote for a reactor that perfectly matches your needs.

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Customizable Laboratory High Temperature High Pressure Reactors for Diverse Scientific Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

People Also Ask

- What is the function of a high-pressure Autoclave in the alkaline leaching process of scheelite? Maximize Tungsten Yield

- What is the role of a high-temperature high-pressure autoclave in HTR simulation? Ensure Reactor Material Durability

- How high pressure is created in a lab? Master Safe and Precise Pressure Generation

- Why is a Teflon-lined high-pressure autoclave required for Mo-Ti-N catalyst synthesis? Ensure Purity and Precision

- What conditions do laboratory high-pressure reactors provide for HTC? Optimize Your Biochar Production Processes