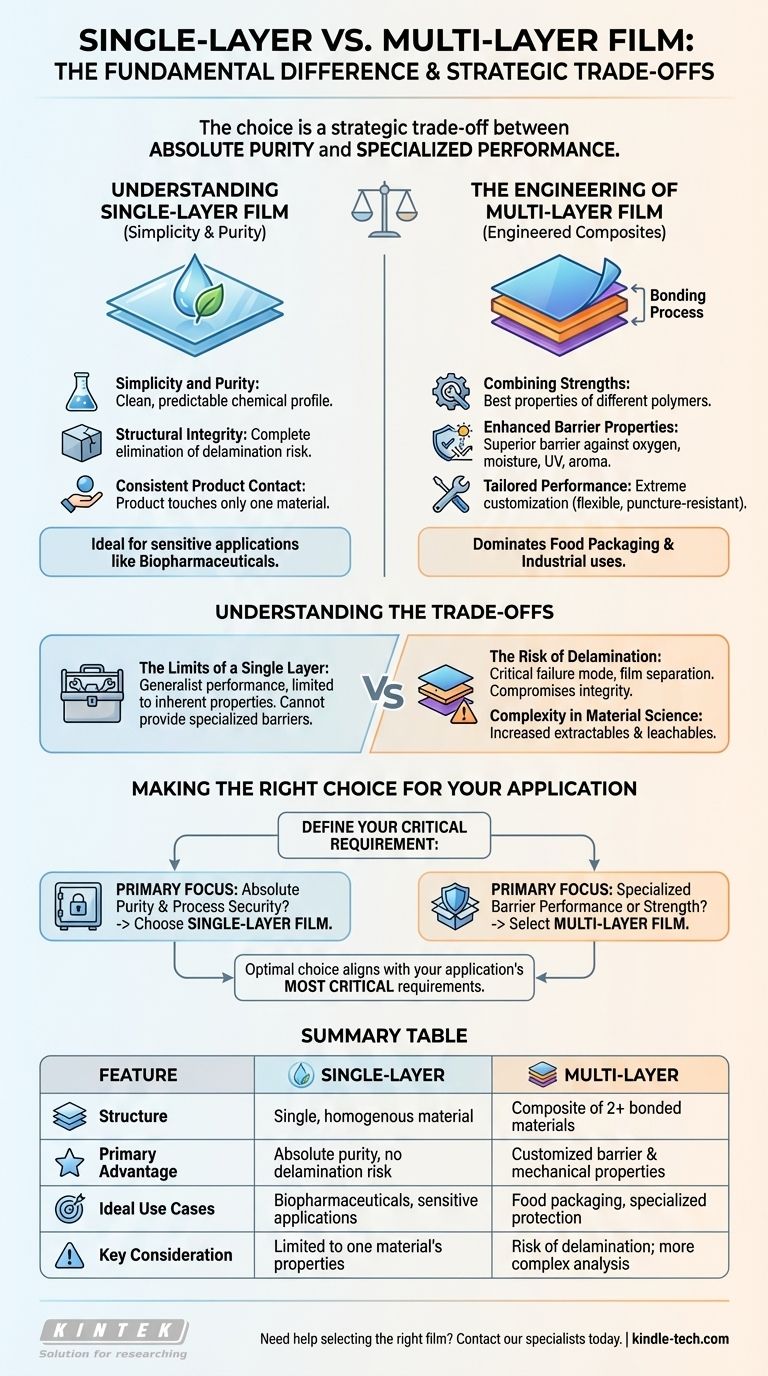

The fundamental distinction between single-layer and multi-layer film lies in their construction and resulting properties. A single-layer film is made from a single, homogenous material, while a multi-layer (or co-extruded) film is a composite structure where two or more different materials are bonded together into a single sheet. This structural difference dictates their ideal use cases, with single-layer films prized for purity and multi-layer films valued for customized performance.

The choice between single and multi-layer film is a strategic trade-off. You are either prioritizing the absolute purity and structural integrity of a single material or the specialized, high-performance characteristics made possible by combining multiple materials.

Understanding Single-Layer Film

A single-layer film is defined by its simplicity. It is manufactured from one type of polymer, resulting in a uniform sheet with consistent properties throughout.

Simplicity and Purity

Because it consists of only one material, a single-layer film has a clean, predictable chemical profile. This is critical in applications where any contamination or chemical leaching is a major concern.

Structural Integrity

The primary advantage cited for single-layer film is the complete elimination of delamination risk. Since there are no separate layers to begin with, they cannot peel apart.

Consistent Product Contact

In sensitive applications like bioprocessing or pharmaceuticals, the contained product only ever touches one, well-characterized material. This simplifies compatibility and safety testing.

The Engineering of Multi-Layer Film

Multi-layer films are engineered composites designed to achieve what a single material cannot. Each layer is chosen for a specific function, and they are bonded together during the manufacturing process.

Combining Strengths

The core purpose of a multi-layer film is to combine the best properties of different polymers. One layer might provide structural strength, another a gas barrier, and a third a heat-sealable surface.

Enhanced Barrier Properties

A multi-layer film can provide a superior barrier against oxygen, moisture, UV light, or aromas. For example, a layer of EVOH (ethylene vinyl alcohol) can be sandwiched between layers of polyethylene to create an excellent oxygen barrier that polyethylene alone lacks.

Tailored Performance

This approach allows for extreme customization. A film can be designed to be flexible yet puncture-resistant, printable on the outside, and food-safe on the inside. This versatility is why multi-layer films dominate the food packaging industry.

Understanding the Trade-offs

Neither film type is universally superior; the choice is driven by the specific demands of the application and the risks you must mitigate.

The Risk of Delamination

This is the critical failure mode for multi-layer films. If the bond between layers fails, the film can separate. This compromises the structural integrity and barrier properties and, in sterile applications, can introduce contaminants into the product.

Complexity in Material Science

With multiple layers comes increased complexity. Each material presents a potential source for extractables and leachables—trace chemicals that can migrate into the product. This makes safety and compatibility analysis more challenging compared to a single-layer film.

The Limits of a Single Layer

A single-layer film is a generalist. While pure and robust, it cannot provide the specialized, high-performance barriers that an engineered multi-layer film can. Its performance is limited to the inherent properties of its one material.

Making the Right Choice for Your Application

To select the correct film, you must first define your most critical requirement. Is it absolute purity or specialized protection?

- If your primary focus is absolute purity and process security: Choose a single-layer film. This is the standard for high-value biopharmaceutical applications where eliminating delamination risk and ensuring a simple chemical contact surface is non-negotiable.

- If your primary focus is specialized barrier performance or mechanical strength: Select a multi-layer film. This is ideal for food packaging or industrial uses where you need to protect a product from oxygen, moisture, or physical damage in a way a single material cannot.

Ultimately, the optimal choice is the one that best protects your product by aligning with your application's most critical requirements.

Summary Table:

| Feature | Single-Layer Film | Multi-Layer Film |

|---|---|---|

| Structure | Single, homogenous material | Composite of 2+ bonded materials |

| Primary Advantage | Absolute purity, no delamination risk | Customized barrier & mechanical properties |

| Ideal Use Cases | Biopharmaceuticals, sensitive applications | Food packaging, specialized protection |

| Key Consideration | Limited to properties of one material | Risk of delamination; more complex analysis |

Need help selecting the right film for your application? The choice between single-layer and multi-layer films is critical for protecting your product's integrity. At KINTEK, we specialize in providing high-performance lab equipment and consumables, including films tailored for demanding environments. Whether your priority is absolute purity for bioprocessing or superior barrier properties for packaging, our experts can guide you to the optimal solution.

Contact our specialists today to discuss your specific requirements and ensure your materials meet the highest standards of performance and safety.

Visual Guide

Related Products

- Aluminum-Plastic Flexible Packaging Film for Lithium Battery Packaging

- Lab Plastic PVC Calender Stretch Film Casting Machine for Film Testing

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Custom Machined and Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

- High Purity Zinc Foil for Battery Lab Applications

People Also Ask

- Why is calendering important? Achieve Superior Fabric Finishing for Your Textiles

- What is the difference between single screw and twin screw? Choose the Right Extruder for Your Process

- What is a two roll mill? Master Polymer Mixing for R&D and Quality Control

- What to do with injection molding? Mass-Produce High-Quality Plastic Parts Efficiently

- What is a two roll mill for rubber compounding? A Foundational Tool for Polymer Processing

- What is the main purpose of vulcanization? Transform Rubber into a Durable, Elastic Material

- What is the process of dual extrusion? Unlock the Power of Multi-Material Manufacturing

- What are the different types of rubber mixing? Choose the Right Method for Your Production Scale