Manual Lab Press

Manual button battery sealing machine (digital display)

Item Number : PC2NS

Price varies based on specs and customizations

- Pressure range

- 0-2T (0-25MPa)

- Piston diameter

- 32mm

- Standard mold

- Standard CR20 series packaging mold

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

The manual button battery sealer is a high-precision packaging device designed for small button batteries (such as CR2032, LR44, etc.), suitable for laboratory research and development, small batch production, and teaching demonstrations. The device uses the principle of mechanical levers and customized molds to quickly complete the pressing and sealing process of the battery shell, ensuring the airtightness of the electrolyte and electrode materials inside the battery, thereby extending the battery life and improving safety. Its simple operation and low cost make it an ideal tool for small and medium-sized battery manufacturers, scientific research institutions, and the electronic maintenance industry.

Detail & Parts

Applications

- The manual button battery sealing machine is widely used in the following scenarios:

- Consumer electronics: button battery packaging for smart watches, calculators, electronic toys, etc.

- Medical equipment: production of micro batteries for hearing aids, portable detectors, etc.

- Industrial field: battery assembly for low-power devices such as IoT sensors and RFID tags.

- Scientific research and education: small batch trial production in university laboratories and new energy material research.

Features

- Simple operation, flexible and efficient

- The ergonomically designed manual lever structure does not require electric drive and can be pressed with one hand.

- Supports quick mold replacement, adapts to button batteries of different sizes (diameter 5-25mm), and has high switching efficiency.

- High-precision packaging process

- Equipped with high-hardness alloy molds, the pressure range is adjustable (0.5-5kN) to ensure uniform sealing of the shell edge without leakage risk.

- The error accuracy is controlled within ±0.05mm, meeting international battery packaging standards.

- Durability and safety are equally important

- The body adopts reinforced steel structure, with excellent wear resistance and a service life of more than 100,000 times.

- Equipped with anti-slip base and protective baffle to avoid component displacement or accidental touch during operation.

- Low-cost maintenance

- No complex electronic components, only lubrication and maintenance are required daily, and the maintenance cost is extremely low.

Advantages

- High cost-effectiveness, quick payback

- Compared with the automatic sealing machine that costs tens of thousands of yuan, the manual model is only 1/10 of the price, which is suitable for enterprises with limited budgets and a short investment return cycle.

- Improve product yield

- Precise pressure control can reduce problems such as battery leakage and short circuit, and the qualified rate of finished products is as high as 99%, reducing material loss costs.

- Adapt to diverse needs

- Support customized mold development, compatible with lithium manganese batteries, alkaline batteries and other types, to meet customers' special specifications.

- Environmental protection and energy saving

- Zero energy consumption design is in line with the trend of green production, especially suitable for enterprises that focus on sustainable development.

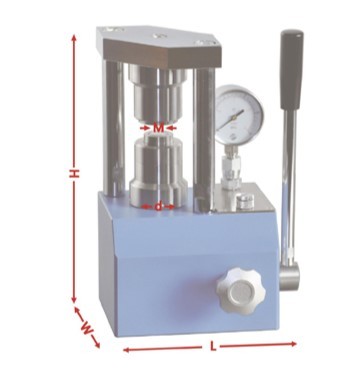

Technical specifications

| Instrument model | PC2NS |

|---|---|

| Pressure range | 0-2T (0-25MPa) |

| Piston diameter | 32mm(d) in chrome-plated oil cylinder |

| Pressure gauge | Digital display 0.00-40.00MPa |

| Standard mold | Standard CR20 series package mold |

| Sealing mold | Optional CR16, CR20, CR24, CR30, etc. |

| Sealing pressure | Generally between 0.8-1.2 tons |

| Shell removal mold | Optional CR16, CR20, CR24, CR30, etc. |

| Shell removal pressure | Generally within 0.4 tons |

| Overall dimensions | 210*165*290mm(LX*W*H) |

| Equipment weight | 12Kg |

| Machine size diagram |  |

Operating steps

1. Put the assembled button battery into the sealing mold of the sealing machine.

2. Tighten the oil drain valve of the sealing machine clockwise.

3. Shake the handle bar back and forth to start pressurizing.

4. Press down the pressure to about 6mpa-8mpa, about 1000kg-1200kg.

5. Loosen the oil drain valve counterclockwise to release the pressure and lower the mold back to the initial position.

6. Take out the sealed button battery from the sealing machine.

7. Put the tested button battery into the demolding mold.

8. Press down the pressure to about 2mpa-5mpa to separate the sealed button battery.

9. Loosen the oil drain valve counterclockwise to release the pressure and lower the mold back to the initial position.

10. Take out the separated button battery from the sealing machine.

Trusted by Industry Leaders

4.8 / 5

Amazingly precise! A must-have for small-scale battery production. Really happy!

4.7 / 5

Excellent value! Easy to use and maintain. Great for our lab. Quick delivery.

4.9 / 5

Super durable and safe. The digital display is a plus! Highly recommended.

4.6 / 5

Improved our battery yield significantly. Worth every penny! Fast shipping.

5.0 / 5

Fantastic machine! Simple, efficient, and cost-effective. Love it!

4.7 / 5

Precise sealing, no leaks! A reliable tool for battery research. Top quality!

4.8 / 5

Easy to operate, even for beginners. Great for teaching demonstrations! A+.

4.9 / 5

Impressive durability. This machine is built to last! Excellent product.

4.6 / 5

Very adaptable to different battery sizes. A versatile and useful tool.

4.7 / 5

Great value for money. Does the job perfectly! Highly recommend!

4.9 / 5

This sealing machine is a game-changer! So happy with the precision.

4.8 / 5

The digital display is so helpful. Makes sealing batteries a breeze! Bravo!

5.0 / 5

Excellent machine, very durable. Worth the investment for our startup!

4.7 / 5

Easy to maintain, no complex parts. A reliable and simple design.

4.6 / 5

Fantastic performance for the price. Great for small batch production.

4.9 / 5

Improved our product quality. The sealing is perfect every time!

4.8 / 5

Simple to use and incredibly effective. A great addition to our lab!

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Manual button battery sealing machine

The manual button battery sealing machine is a high-precision packaging device designed specifically for small button batteries (such as CR2032, LR44 and other models). It is suitable for laboratory research and development, small batch production and teaching demonstrations.

Electric button battery sealing machine

The electric button battery sealing machine is a high-performance packaging equipment designed for mass production of button batteries (such as CR series, LR series, SR series, etc.), suitable for electronic manufacturing, new energy research and development, and industrial automation production lines.

Button Battery Tablet Press Sealing Mold for Lab Use

The sealing die is essential for assembling button batteries, ensuring components like the anode, cathode, and electrolyte are securely enclosed.

Button Battery Disassembly and Sealing Mold for Lab Use

The simple sealing and disassembly mold can be directly used on ordinary tablet presses, which can save costs, is convenient and fast, and can be used to encapsulate and disassemble button batteries. Other specifications can be customized.

Button Battery Case for Battery Lab Applications

Button batteries are also known as micro batteries. It looks like a small button-shaped battery. Usually larger in diameter and thinner in thickness.

Button Battery Case Gasket for Battery Lab Applications

The gasket prevents the deformation of the internal material, and the spring sheet is conducive to the tight contact inside the battery to prevent loosening.

Laboratory Hydraulic Press Lab Pellet Press for Button Battery

Efficiently prepare samples with our 2T Button Battery Press. Ideal for material research labs and small-scale production. Small footprint, lightweight, and vacuum-compatible.

Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

Efficiently prepare samples with Cylindrical Lab Electric Heating Press Mold. Fast heating, high temp & easy operation. Custom sizes available. Perfect for battery, ceramic & biochemical research.

Button Battery Storage Box for Battery Lab

Button-type battery storage box, detachable, high-quality PP environmental protection material; suitable for small objects/chemicals, etc., thickened, compressive, durable, and available in a variety of styles.

Nickel Aluminum Tabs for Soft Pack Lithium Batteries

Nickel tabs are used to manufacture cylindrical and pouch batteries, and positive aluminum and negative nickel are used to produce lithium-ion and nickel batteries.

Battery Lab Equipment 304 Stainless Steel Strip Foil 20um Thick for Battery Test

304 is a versatile stainless steel, which is widely used in the production of equipment and parts that require good overall performance (corrosion resistance and formability).

Hydrophilic Carbon Paper TGPH060 for Battery Lab Applications

Toray carbon paper is a porous C/C composite material product (composite material of carbon fiber and carbon) that has undergone high-temperature heat treatment.

Polyethylene Separator for Lithium Battery

The polyethylene separator is a key component of lithium-ion batteries, located between the positive and negative electrodes. They allow the passage of lithium ions while inhibiting electron transport. The performance of the separator affects the capacity, cycle and safety of the battery.

Graphite Vacuum Furnace Negative Material Graphitization Furnace

Graphitization furnace for battery production has uniform temperature and low energy consumption. Graphitization furnace for negative electrode materials: an efficient graphitization solution for battery production and advanced functions to enhance battery performance.

Battery Lab Equipment Battery Capacity and Comprehensive Tester

The scope of application of the battery comprehensive tester can be tested: 18650 and other cylindrical, square lithium batteries, polymer batteries, nickel-cadmium batteries, nickel-metal hydride batteries, lead-acid batteries, etc.

Cylindrical Battery Steel Case for Battery Lab

Lithium-ion battery casing suppresses battery polarization, reduces thermal effects, and improves rate performance.

CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

Discover high-vacuum CF/KF flange electrode feedthroughs, ideal for vacuum systems. Superior sealing, excellent conductivity, and customizable options.

Platinum Sheet Electrode for Battery Lab Applications

Platinum sheet is composed of platinum, which is also one of the refractory metals. It is soft and can be forged, rolled and drawn into rod, wire, plate, tube and wire.

Laboratory Vibratory Sieve Shaker Machine for Dry and Wet Three-Dimensional Sieving

KT-VD200 can be used for sieving tasks of dry and wet samples in the laboratory. The screening quality is 20g-3kg. The product is designed with a unique mechanical structure and an electromagnetic vibrating body with a vibration frequency of 3000 times per minute.

Related Articles

PTFE gasket: an all-around solution for flange sealing

Polytetrafluoroethylene (PTFE) gaskets have become an ideal choice in the field of flange sealing due to their unique chemical stability and high temperature resistance.

The Invisible Architecture of Precision: Mastery Before the Current Flows

Achieve electrochemical accuracy by mastering the four pillars of preparation: rigorous inspection, cleaning, installation, and electrolyte management.