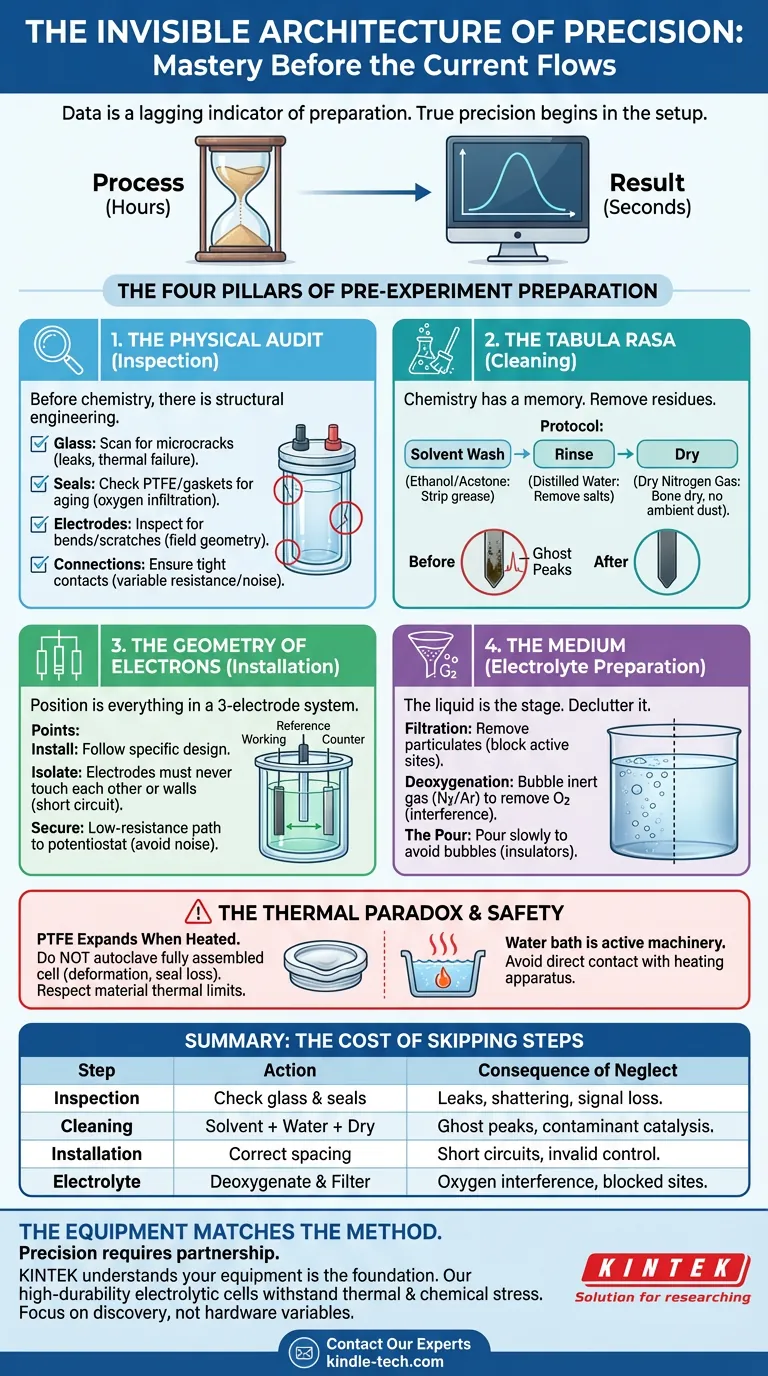

The Invisible Architecture of Precision: Mastery Before the Current Flows

Data is a lagging indicator of preparation.

In the laboratory, we are often seduced by the result—the curve on the monitor, the efficiency calculation, the publication. But in electrochemistry, the result is merely the final echo of a process that began hours before the potentiostat was turned on.

The double-layer water-bath electrolytic cell is a marvel of thermal control and reaction isolation. Yet, it is an unforgiving instrument. It does not tolerate shortcuts.

If you treat the setup as a formality, you introduce noise. If you treat it as a ritual, you manufacture truth.

Here is the anatomy of a flawless setup, designed to remove the human variable from the scientific equation.

The Four Pillars of Pre-Experiment Preparation

There is a difference between a setup that looks ready and one that is ready. That difference is usually found in the invisible details.

1. The Physical Audit (Inspection)

Before chemistry, there is structural engineering.

A double-layer cell operates under thermal stress. The outer jacket circulates water; the inner chamber holds the reaction. A microscopic fracture in the glass is not just a cosmetic defect; under the thermal expansion of a water bath, it is a catastrophic failure waiting to happen.

The Checklist:

- The Glass: Scan for microcracks. If the light catches a fracture, the cell is compromised.

- The Seals: PTFE (Teflon) is miraculous but finite. Check the lid and gaskets for brittleness or aging. A bad seal means oxygen infiltration, and oxygen is the enemy of precision.

- The Electrodes: These are your sensors. A bent auxiliary electrode or a scratched working electrode changes the geometry of the field.

- The Connections: A loose wire is a variable resistor you didn’t account for. Ensure contacts are tight.

2. The Tabula Rasa (Cleaning)

Chemistry has a memory.

Residues from last week’s experiment are the ghosts that haunt today’s data. If you skip meticulous cleaning, you are not testing a new reaction; you are testing a mixture of your current hypothesis and your past negligence.

The Protocol:

- Solvent Wash: Use ethanol or acetone to strip organic grease.

- The Rinse: Follow with distilled or deionized water. You are removing the solvent and inorganic salts.

- The Dry: Use dry nitrogen gas. Do not let it air dry with ambient dust. The cell must be bone dry.

3. The Geometry of Electrons (Installation)

In a three-electrode system, position is everything.

The electric field is shaped by the physical location of your components. If the working electrode touches the wall, you have a short. If the reference electrode is too far, you introduce uncompensated resistance.

- Install according to the specific design.

- Isolate the electrodes. They must never touch each other or the glass walls.

- Secure the path. The wire connecting to the potentiostat must offer low resistance. High resistance here looks like noise in your data.

4. The Medium (Electrolyte Preparation)

The liquid is the stage. If the stage is cluttered, the actors cannot perform.

- Filtration: If there are particulates, filter them. A particle sticking to an electrode surface blocks the reaction site.

- Deoxygenation: This is the step most often rushed. Oxygen is electrochemically active. If you do not bubble inert gas (Nitrogen/Argon) through the solution, you will see oxygen reduction peaks that mimic or mask your data.

- The Pour: Pour slowly. Bubbles are insulators. A bubble on your electrode is a blind spot in your vision.

The Thermal Paradox

The double-layer cell exists to control temperature, but temperature control introduces material constraints.

The outer jacket keeps the internal environment uniform. Reaction rates and diffusion coefficients are slaves to temperature; without the water bath, they fluctuate wildly.

However, you must respect the materials. PTFE expands when heated.

If you autoclave the fully assembled cell, the PTFE lid will deform and never fit again. You can sterilize the glass, but the plastics have thermal limits. Respect the coefficient of expansion, or you will lose your seal.

Safety as a System

The water bath is an active energy source. It gets hot.

The cell contains chemicals.

Avoid direct skin contact with the heating apparatus. Treat the water bath not as a bucket of water, but as a piece of active machinery.

Summary: The Cost of skipping Steps

We often skip steps to save time. But a failed experiment costs days. A rigorous setup costs minutes.

| Step | The Action | The Consequence of Neglect |

|---|---|---|

| Inspection | Check glass & seals | Leaks, thermal shattering, signal loss. |

| Cleaning | Solvent + Water + Dry | Ghost peaks, catalysis from contaminants. |

| Installation | Correct spacing | Short circuits, invalid potential control. |

| Electrolyte | Deoxygenate & Filter | Oxygen interference, blocked active sites. |

The Equipment Matches the Method

You can have the most disciplined process in the world, but you cannot overcome the limitations of inferior hardware. Precision requires a partnership between the scientist's method and the manufacturer's engineering.

At KINTEK, we understand that your equipment is the foundation of your research. We specialize in lab equipment and consumables—including high-durability electrolytic cells—that are built to withstand the rigors of thermal stress and chemical exposure. We build the reliability so you can focus on the discovery.

Don't let your hardware be the variable you can't control.

Visual Guide

Related Products

- Platinum Sheet Electrode for Battery Lab Applications

- Button Battery Disassembly and Sealing Mold for Lab Use

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Manual button battery sealing machine

- Manual button battery sealing machine (digital display)

Related Articles

- Reference Electrodes: Calomel, Silver Chloride, and Mercury Sulfate - A Comprehensive Guide

- Understanding Electrodeposition with Electrochemical Electrodes

- Electrochemical Electrodes in Chemical Analysis

- Electrolytes and Electrochemical Electrodes

- Understanding Quartz Electrolytic Cells: Applications, Mechanisms, and Advantages