Manual Lab Press

Laboratory manual slicer

Item Number : PT10

Price varies based on specs and customizations

- Mold material

- 3Cr13 (quenched stainless steel)

- Slice size

- Φ10,Φ12,Φ14,Φ15,Φ16,Φ18,Φ19(d)

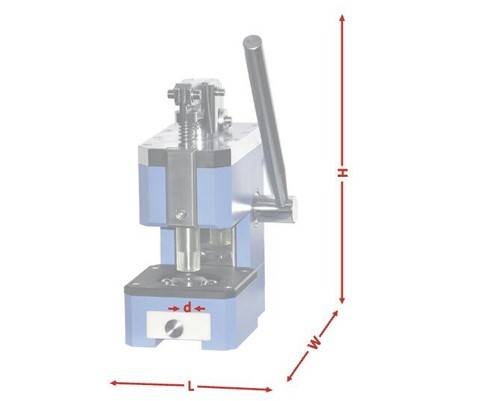

- Overall dimensions

- 120*200*280mm(L*W*H)

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

The manual slicer is a high-precision cutting device designed for laboratories, industry and medical fields. It is suitable for the preparation of thin slices of various materials such as paraffin samples, biological tissues, battery materials, food, etc. Its core design combines mechanical stability and operational convenience, supports flexible manual control mode, and can meet the stringent requirements of scientific research analysis, pathological diagnosis, material testing and other scenarios.

Detail & Parts

Applications

Manual slicers are widely used in the following scenarios:

- Laboratory research: biological tissue slicing (such as pathological testing), plant sample preparation, polymer material thin slice processing.

- Food industry: uniform slicing of vegetables, meat, cheese and other foods to improve processing efficiency and product consistency.

- Industrial manufacturing: precision slicing of materials such as rubber, plastic, and soft metal for quality inspection or small parts production.

- Education and training: practical teaching in medical schools and vocational schools to help students master basic slicing techniques.

Features

- Easy to operate and flexible to adapt

- The manual rotating wheel or lever design is adopted, and no electric drive is required. The cutting rhythm can be controlled by one hand, which is suitable for power-free environments.

-

- Equipped with a thickness adjustment knob, the slicing range covers 0.1-10mm, and the accuracy reaches ±0.05mm, which meets the diverse cutting needs.

- High-precision cutting performance

- Equipped with high-hardness stainless steel blades, it supports quick disassembly and replacement, and the blade angle is adjustable (10°-30°) to adapt to different material hardness.

- The non-slip sample fixing groove design ensures that there is no displacement during the material cutting process, and the slices are flat and without burrs.

- Safe and durable, simple maintenance

- The body adopts an all-metal frame and anti-corrosion coating, which has strong load-bearing capacity and long service life.

- Built-in safety shield and blade locking device to avoid the risk of accidental touch during operation, in line with industrial safety standards.

- Low cost investment

- Only cleaning the blade and lubricating the track are required on a daily basis, and the maintenance cost is extremely low.

Technical specifications

| Instrument model | PT10 |

| Mold material | 3Cr13 (quenched stainless steel) |

| Slice size | Φ10,Φ12,Φ14,Φ15,Φ16,Φ18,Φ19(d) |

| Overall dimensions | 120*200*280mm(L*W*H) |

| Equipment weight | 10kg |

| Machine size diagram |  |

Operating steps

1. Install the upper punch into the slicer.

2. Tighten the front locking screw to fix the upper punch.

3. Put in the matching lower die.

4. After the punch is aligned, tighten the fixing screw of the lower die.

5. Put the sample into the slicer for punching

6. Take out the cut sample.

Trusted by Industry Leaders

FAQ

What Are The Advantages Of Using A Manual Press?

How Does A Manual Press Work?

What Types Of Tasks Can Be Performed Using A Manual Press?

What Is Manually Operated Lab Press?

4.9 / 5

Incredible precision! Perfect slices every time. A must-have for any lab. Worth every penny!

4.7 / 5

Easy to use and maintain. Solid build quality. Great for educational purposes. Highly recommend!

4.8 / 5

A game-changer in our food processing. Consistent slices, boosting efficiency. Couldn't be happier!

4.6 / 5

Simple, effective, and safe. Perfect for delicate tissue samples. A reliable tool!

5.0 / 5

The precision is outstanding! This slicer has significantly improved our research outcomes.

4.9 / 5

Great value for money. Durable and accurate. Perfect for our material testing lab.

4.7 / 5

Love the manual control. It gives me the flexibility I need for intricate slicing. Excellent!

4.8 / 5

Easy to clean and very safe. A great addition to our pathology lab. Highly satisfied.

4.9 / 5

The adjustable blade is a fantastic feature. Works great for different material hardness.

4.7 / 5

Very precise and durable. Perfect for our needs in battery material slicing.

4.8 / 5

Remarkable tool! The slices are incredibly consistent. An excellent investment.

4.6 / 5

Great build. Safe and easy operation, perfect for students. A fantastic teaching aid.

4.9 / 5

Exceeded my expectations! The precision is top-notch. Perfect for our research.

4.7 / 5

Durable construction and easy maintenance. Couldn't ask for a better slicer!

4.8 / 5

So easy to operate and clean! This slicer has improved our workflow immensely.

4.6 / 5

Precise cuts every time. Perfect for food sample preparation. Highly recommended.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Laboratory Grinding Mill Mortar Grinder for Sample Preparation

KT-MG200 mortar grinder can be used for mixing and homogenizing powder, suspension, paste and even viscous samples. It can help users realize the ideal operation of sample preparation with more regularization and higher repeatability.

Laboratory Manual Hydraulic Pellet Press for Lab Use

Efficient sample preparation with small footprint Manual Lab Hydraulic Press. Ideal for material researching labs, pharmacy, catalytic reaction, and ceramics.

Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

The desktop fast steam sterilizer is a compact and reliable device used for rapid sterilization of medical, pharmaceutical, and research items. It efficiently sterilizes surgical instruments, glassware, medicines, and resistant materials, making it suitable for various applications.

Laboratory Planetary Ball Mill Cabinet Planetary Ball Milling Machine

The vertical cabinet structure combined with ergonomic design enables users to obtain the best comfortable experience in standing operation. The maximum processing capacity is 2000ml, and the speed is 1200 revolutions per minute.

Three-dimensional electromagnetic sieving instrument

KT-VT150 is a desktop sample processing instrument for both sieving and grinding. Grinding and sieving can be used both dry and wet. The vibration amplitude is 5mm and the vibration frequency is 3000-3600 times/min.

Engineering Advanced Fine Ceramics Head Tweezers with Pointed Elbow Zirconia Ceramic Tip

Zirconia ceramic tweezers are a high-precision tool made of advanced ceramic materials, especially suitable for operating environments that require high precision and corrosion resistance. This type of tweezers not only has excellent physical properties, but is also popular in the medical and laboratory fields because of its biocompatibility.

Laboratory Test Sieves and Vibratory Sieve Shaker Machine

Efficiently process powders, granules, and small blocks with a high-frequency vibration sieve. Control vibration frequency, screen continuously or intermittently, and achieve accurate particle size determination, separation, and classification.

Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

Controlled environment lab press machine for glove box. Specialized equipment for material pressing and shaping with high precision digital pressure gauge.

Laboratory Wet Three-Dimensional Vibratory Sieve Shaker Machine

The wet three-dimensional vibrating sieving instrument focuses on solving the sieving tasks of dry and wet samples in the laboratory. It is suitable for sieving 20g - 3kg dry, wet or liquid samples.

Related Articles

The Invisible Architecture of Precision: Mastery Before the Current Flows

Achieve electrochemical accuracy by mastering the four pillars of preparation: rigorous inspection, cleaning, installation, and electrolyte management.

The Art of the Empty Vessel: Preparing Quartz Electrolytic Cells for Absolute Precision

Reliable electrochemical data isn't just about the reaction; it's about the setup. Discover the systematic approach to preparing quartz cells for perfect fidelity.

The Invisible Variable: Why Cell Maintenance Defines Electrochemical Truth

Data fidelity begins at the sink. Discover the systematic approach to cleaning electrolytic cells and why the integrity of your glassware defines your results.

The Fragile Vessel of Truth: A Maintenance Manifesto for Electrolytic Cells

Data integrity relies on equipment health. Discover the psychological and technical art of maintaining five-port electrolytic cells for reproducible science.

The Transparency Paradox: Mastering the Fragile Art of Electrolytic Cells

Glass electrolytic cells are precision instruments, not simple containers. Learn the systematic approach to handling glass to ensure safety and data integrity.

The Architecture of Control: Why Thermal Stability Defines Electrolysis Success

Discover how double-layer water-bath electrolytic cells eliminate thermal variables, ensuring accuracy and reproducibility in electrochemical research.

The Invisible 90%: Why Spectroelectrochemistry Succeeds Before It Begins

Experimental success isn't just about the reaction; it's about the vessel. Master the 4-step preparation protocol for optical electrolytic cells to ensure data integrity.

The Silent Half of the Experiment: The Ritual of Cell Preservation

Post-experiment care isn't just cleanup; it's calibration for the future. Learn the precise protocols for maintaining super-sealed electrolytic cells.

The Architecture of Control: Decoding the Five-Port Electrolytic Cell

Unlock the specifics of the standard five-port electrolytic cell (3x Φ6.2mm, 2x Φ3.2mm) and why precise customization is the key to reproducible electrochemistry.

The Art of Resistance: Why Your Electrolytic Cell Needs Breathing Room

Short circuits in electrolytic cells aren't just accidents; they are geometry failures. Learn how to control the electrical path and protect your lab equipment.

The Thermodynamics of a Perfect Seal: A Component-Level Approach to Sterilization

Learn why autoclaving your entire electrolytic cell destroys the seal. A guide to understanding material properties and protecting your experiments.

The Transparency Paradox: Mastering the Fragile Precision of All-Quartz Cells

Quartz cells offer unmatched optical purity but demand rigorous discipline. Learn the essential protocols for inspection, thermal management, and handling.