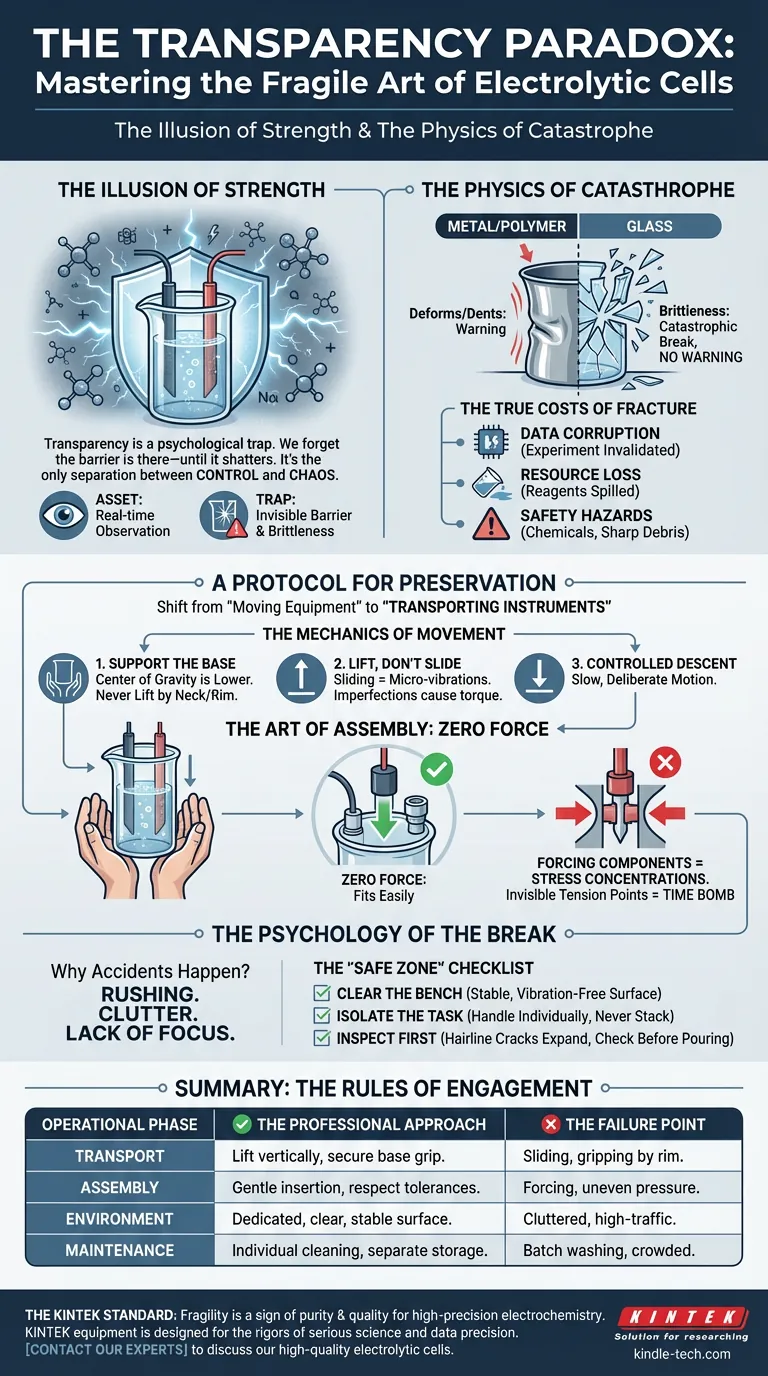

The Illusion of Strength

In the laboratory, we spend most of our time looking through glass, not at it.

This transparency is its greatest asset, allowing us to witness chemical reactions in real-time. However, it is also a psychological trap. Because the barrier is invisible, we often forget it is there—until it shatters.

The electrolytic cell is not merely a vessel; it is a critical scientific instrument. It is the only thing separating a controlled electrochemical environment from chaotic failure.

When we handle the glass body of a cell, we are managing a risk equation. The glass is brittle. It does not forgive mistakes. It does not bend to accommodate our impatience.

The Physics of Catastrophe

Glass possesses a material property that engineers respect and operators often fear: brittleness.

Unlike metals or polymers, which might deform or dent under stress, glass maintains its shape until it reaches a catastrophic breaking point. There is no warning. There is no yielding.

When an electrolytic cell fractures, the cost is rarely just the replacement of the glass. The true costs are:

- Data corruption: The closed system is breached, invalidating the experiment.

- Resource loss: Valuable reagents and electrolytes are spilled.

- Safety hazards: Chemical exposure and sharp debris create an immediate danger zone.

A Protocol for Preservation

To protect the integrity of the experiment, we must adopt a deliberate system of handling. This requires shifting from a mindset of "moving equipment" to "transporting instruments."

The Mechanics of Movement

Gravity and friction are the enemies of glass. To mitigate these forces:

- Support the Base: Never lift a cell by its neck or rim. Always cup the base. The structural center of gravity is lower than you think.

- Lift, Don't Slide: Sliding a cell across a benchtop creates microscopic vibrations. If the glass catches on an imperfection in the surface, the resulting torque can cause an immediate fracture.

- Controlled Descent: When placing the cell down, the motion should be slow and deliberate.

The Art of Assembly

The most dangerous moment for an electrolytic cell is often during assembly—inserting electrodes or connecting gas lines.

The rule is simple: Zero Force.

If a component does not fit easily, something is wrong. Applying pressure to force a fit creates stress concentrations. These invisible tension points turn the glass into a time bomb, waiting for a slight temperature shift or vibration to shatter.

The Psychology of the Break

Why do accidents happen? Rarely is it a lack of skill. Usually, it is a lack of focus.

We rush. We try to carry two things at once. We operate in a cluttered workspace where the cell has to fight for space against beakers and notebooks.

Accidents are the result of systems that allow for error. To prevent breakage, we must engineer our environment and our behavior.

The "Safe Zone" Checklist:

- Clear the Bench: The cell requires a stable, vibration-free surface.

- Isolate the Task: Handle the cell individually. Never stack it with other glassware.

- Inspect First: A hairline crack is a fracture waiting to expand. Check before you pour.

Summary: The Rules of Engagement

The following framework outlines the difference between casual handling and professional preservation.

| Operational Phase | The Professional Approach | The Failure Point |

|---|---|---|

| Transport | Lift vertically with a secure grip on the base. | Sliding horizontally or gripping by the rim. |

| Assembly | Gentle insertion; respect tolerances. | Forcing components; uneven pressure. |

| Environment | Dedicated, clear, stable surface. | Cluttered, high-traffic bench space. |

| Maintenance | Individual cleaning; separate storage. | Washing in batches; crowded storage. |

The KINTEK Standard

The fragility of glass is a constraint, but it is also a sign of quality. It implies purity, transparency, and chemical inertness—qualities essential for high-precision electrochemistry.

At KINTEK, we understand that your equipment is the foundation of your research. We specialize in lab equipment and consumables designed to withstand the rigors of serious science while delivering the precision your data demands.

We build instruments for those who understand that the details matter.

Contact Our Experts to discuss how our high-quality electrolytic cells can improve the safety and reliability of your laboratory workflow.

Visual Guide

Related Products

- Electrolytic Electrochemical Cell with Five-Port

- Super Sealed Electrolytic Electrochemical Cell

- Double-Layer Water Bath Electrolytic Electrochemical Cell

- Electrolytic Electrochemical Cell for Coating Evaluation

- Optical Water Bath Electrolytic Electrochemical Cell

Related Articles

- The Silent Dialogue: Mastering Control in Electrolytic Cells

- The Fragile Vessel of Truth: A Maintenance Manifesto for Electrolytic Cells

- The Architecture of Precision: Why the Invisible Details Define Electrochemical Success

- The Invisible Architecture of Accuracy: Optimizing the Five-Port Electrolytic Cell

- The Architecture of Precision: Mastering Electrolytic Cell Maintenance