The Invisible Cost of Entropy

In every laboratory, there is a silent war being fought between precision and entropy.

We often think of science as the "Eureka" moments—the result on the screen, the published graph, the breakthrough. But the reality of electrochemical research is far more mechanical. It is a discipline of maintenance.

The five-port water bath electrolytic cell is a marvel of containment. It holds the chemistry, controls the temperature, and facilitates the reaction. But like any complex system, it naturally degrades.

The danger isn't that the machine stops working. The danger is that it continues to work, but produces slightly wrong data.

A compromised seal or a corroded electrode doesn't always wave a red flag. It whispers lies into your dataset. To protect the truth of your research, you must adopt a philosophy of rigorous, proactive inspection.

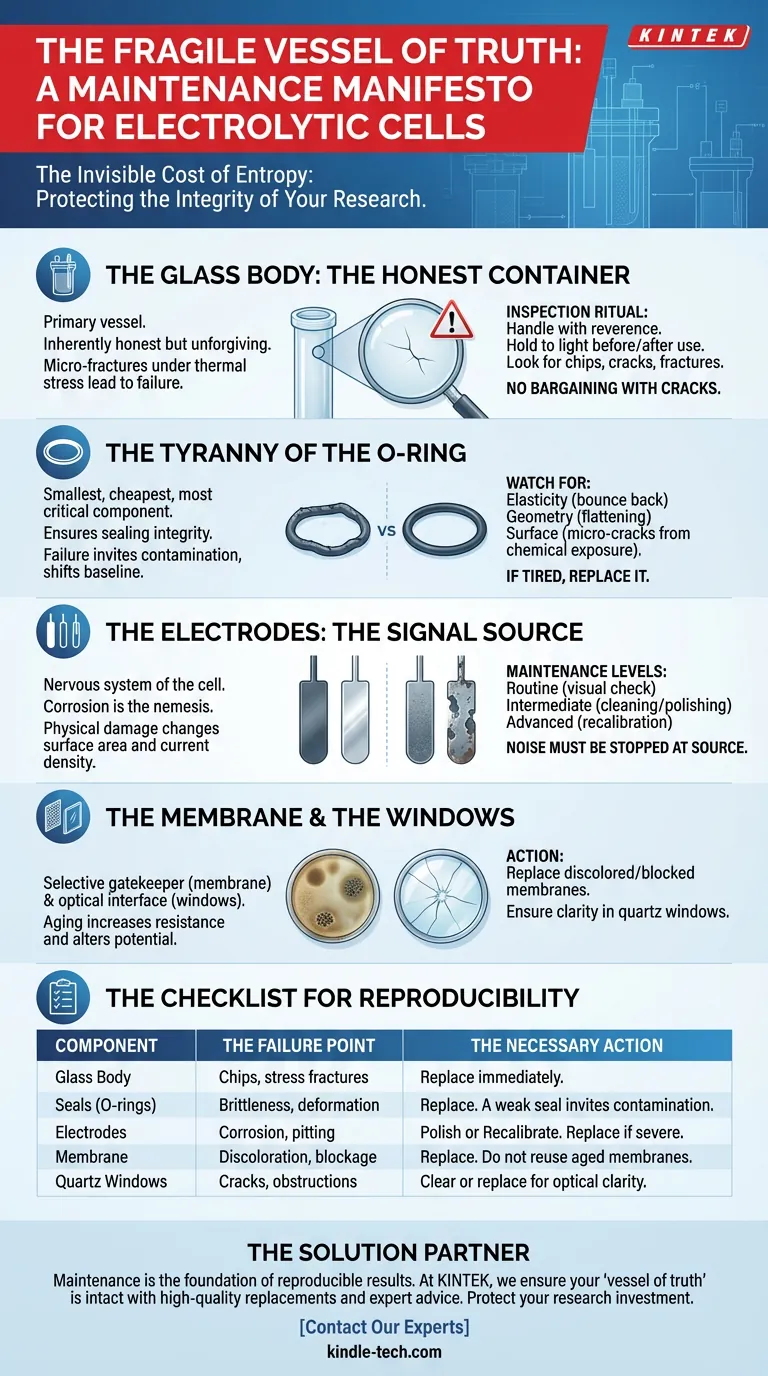

The Glass Body: The Honest Container

The cell body is the primary vessel. Because it is made of glass, it is inherently honest—it shows you exactly what is happening inside.

But glass is also unforgiving.

There is a psychological tendency to ignore "minor" scratches. We tell ourselves it’s just cosmetic. In electrochemistry, however, a micro-fracture under thermal stress (from the water bath) can lead to catastrophic failure during an experiment.

The Inspection Ritual:

- Handle the cell with the reverence due a fragile object.

- Before and after every use, hold it to the light.

- Look for chips, cracks, or fractures.

If you find a crack, do not bargain with it. A compromised vessel is a safety hazard and a variable you cannot control.

The Tyranny of the O-Ring

The O-ring is the smallest, cheapest, and most critical component in the assembly.

It is responsible for the sealing integrity. It keeps the outside world out and your inert atmosphere in. If the seal fails, oxygen enters. Reactions change. Your baseline shifts.

Rubber ages differently than glass. It doesn't shatter; it forgets its shape. It becomes brittle, cracks, or deforms permanently.

What to watch for:

- Elasticity: Does it bounce back?

- Geometry: Is it flattened?

- Surface: Are there micro-cracks from chemical exposure?

If the O-ring looks tired, replace it. It is the cheapest insurance policy you can buy for your data.

The Electrodes: The Signal Source

If the cell body is the skeleton, the electrodes are the nervous system. This is where the physical reality of the solution translates into digital data.

Corrosion is the nemesis here.

You are looking for pitting on the working, auxiliary, or reference electrodes. Physical damage changes the surface area. A changed surface area changes current density.

Maintenance Levels:

- Routine: Visual check for pitting or bending.

- Intermediate: Cleaning and polishing.

- Advanced: Recalibration.

You cannot compensate for a damaged electrode with software. The noise must be stopped at the source.

The Membrane and The Windows

The ion exchange membrane is a selective gatekeeper. It allows specific ions to pass while blocking others.

When a membrane ages, it doesn't just stop working; it gets clogged or discolored. This increases resistance and alters the potential distribution across the cell. If it looks discolored or physically damaged, its ability to facilitate true ion exchange is gone.

Similarly, if your setup uses quartz windows for optical measurements, clarity is paramount. A crack here isn't just a leak risk; it is an optical distortion.

The Limits of Heroism

There is a specific kind of engineer’s arrogance that suggests we can fix anything.

But knowing what not to fix is a hallmark of expertise.

Standard maintenance covers cleaning, O-rings, and electrode polishing. However, certain failures require a hard stop.

Do not attempt to fix:

- Water Bath Circulation Systems: If the temperature control fails, disassembling the pump or heating elements is dangerous.

- Structural Bondings: Permanent seals that have cracked require professional repair. Glue is not a solution in a chemical environment.

- Severe Electrical Faults: If the circuit is shorting, you need expert diagnosis, not a soldering iron.

Attempting to fix these complex issues often transforms a repairable part into a total loss.

The Checklist for Reproducibility

Your maintenance rigor should match your stakes.

If you are doing qualitative teaching demonstrations, a visual check suffices. If you are doing high-precision quantitative research, your checklist must be absolute.

Here is the protocol for preserving data integrity:

| Component | The Failure Point | The Necessary Action |

|---|---|---|

| Glass Body | Chips, stress fractures | Replace immediately. Do not risk thermal shock. |

| Seals (O-rings) | Brittleness, deformation | Replace. A weak seal invites contamination. |

| Electrodes | Corrosion, pitting | Polish or Recalibrate. Replace if severe. |

| Membrane | Discoloration, blockage | Replace. Do not reuse aged membranes. |

| Quartz Windows | Cracks, obstructions | Clear or replace to ensure optical clarity. |

The Solution Partner

Maintenance is not a chore; it is the foundation of reproducible results. It is the difference between guessing and knowing.

At KINTEK, we understand the engineer's romance with precision. We don't just sell equipment; we provide the assurance that your "vessel of truth" is intact. Whether you need high-quality replacement seals, pristine electrodes, or expert advice on a failing circulation system, we are here to ensure the hardware never gets in the way of the science.

Protect your research investment.

Visual Guide

Related Products

- Electrolytic Electrochemical Cell with Five-Port

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- Super Sealed Electrolytic Electrochemical Cell

- Electrolytic Electrochemical Cell for Coating Evaluation

- Double-Layer Water Bath Electrolytic Electrochemical Cell

Related Articles

- The Invisible Architecture of Accuracy: Optimizing the Five-Port Electrolytic Cell

- The Architecture of Precision: Mastering the Five-Port Water Bath Electrolytic Cell

- The Symphony of Coefficients: Why Your Electrolytic Cell Cannot Be a Monolith

- The Transparency Paradox: Mastering the Fragile Art of Electrolytic Cells

- The Architecture of Precision: Mastering Electrolytic Cell Maintenance