vacuum pump & cold trap chiller

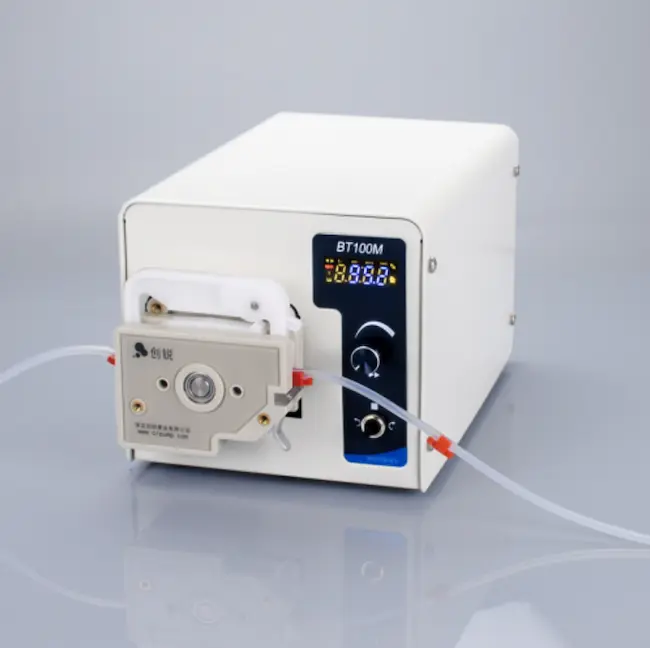

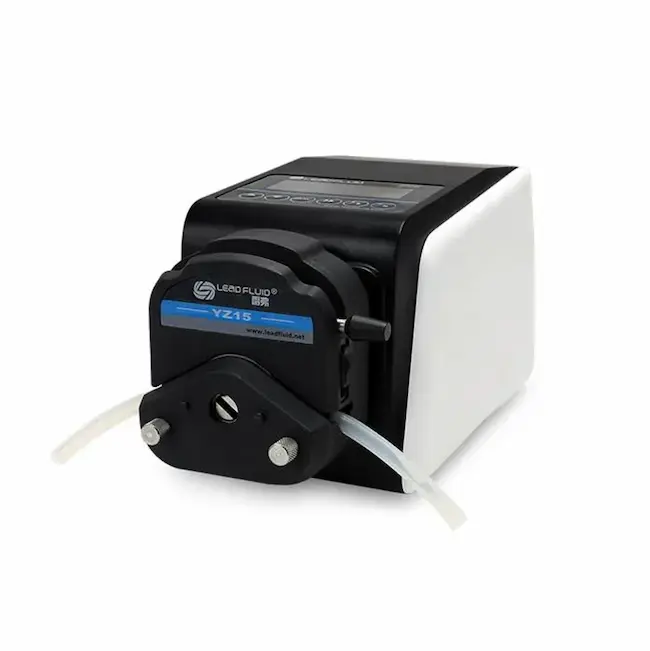

Variable Speed Peristaltic Pump

Item Number : KT-VSP

Price varies based on specs and customizations

- Speed Adjustable Range

- 0.1-200 rpm

- Flow Range

- 0.007-825 ml/min

- Power Supply Voltage

- AC100V~AC250V 50Hz/60Hz or DC100V~DC275V

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Product Overview

The KT-VSP series peristaltic pumps integrate advanced speed control technology and multiple control modes, meeting stringent demands for accurate fluid metering and delivery. Their compact design and stable performance ensure efficient and reliable liquid handling processes across various fields.

Application Areas

The KT-VSP series peristaltic pumps are widely used in:

- Laboratories: Reagent dispensing, media transfer, and precision liquid preparation.

- Medical Devices: In vitro diagnostic equipment, dialysis equipment, and infusion systems.

- Pharmaceutical & Bioengineering: Transfer of fermentation broths and cell culture media, vaccine filling.

- Industrial Production: Fluid transfer and metering in chemical, water treatment, and food & beverage industries.

- Environmental Monitoring: Water sample collection and wastewater treatment.

Details & Parts

This series of peristaltic pumps consists of the following core components:

- Drive: The core of power and control, featuring a built-in high-performance processor and precision motor. The robust housing, with an IP31 protection rating, is suitable for various working environments.

- Pump Head: A selection of models like 01 and 02 is available, equipped with 3 rollers to ensure smooth pulsation. The pump head is designed for quick and easy tubing changes.

- Tubing: Available in various specifications to accommodate different flow rates and chemical compatibility requirements.

- Control Panel: Equipped with a 3-digit LED display for clear visibility of speed or timing. Physical knobs and buttons allow for easy control of start/stop, direction change, speed adjustment, and full-speed operation.

- External Control Interfaces: The rear panel integrates multiple interfaces, supporting RS485 communication, footswitches, and various analog (0-5V, 0-10V, 4-20mA) and frequency (0-10KHz) signals for easy system integration.

Key Features

- Precise Speed Adjustment & Control: Speed range of 0.1-200 rpm with a resolution up to 0.1 rpm, ensuring accurate flow control.

- Multiple Control Modes: Supports internal control (speed, start/stop, forward/reverse, full speed) and various external control options (0-10KHz, 0-5V, 0-10V, 4-20mA, RS485, footswitch), flexibly adapting to diverse application scenarios.

- Efficient Timing Function: Timing range from 0.1 seconds to 99 hours, with an accuracy of less than 20 milliseconds, meeting demands for long-term or cyclical dispensing.

- Intuitive Display: A 3-digit LED display provides clear visibility of the operating status.

- Wide Flow Range: Covers a flow range from 0.007-825 ml/min depending on the pump head and tubing combination.

- Robust and Durable: IP31 protection rating, suitable for various working environments.

Technical Specifications

| Parameter | Description |

|---|---|

| Product Models | KT-VSP-01, KT-VSP-02, KT-VSP-03, KT-VSP-04 |

| Power Supply Voltage | AC100V AC250V 50Hz/60Hz or DC100V DC275V |

| Standby Power (Stopped) | <11W |

| Normal Operating Power | <20W |

| Startup Power | <40W |

| Display Method | 3-Digit LED |

| Speed Adjustable Range | 0.1-200 rpm |

| Speed Resolution (rpm) | 0.1 rpm (speed ≤ 100 rpm); 1 rpm (speed > 100 rpm) |

| Timing Range | 0.1 sec - 99 hours |

| Timing Accuracy | <20 ms |

| Timing Adjustment Method | Manual: Stepped Adjustment |

| Communication | Continuous Adjustment |

| Internal Control | Speed, Start/Stop, Forward/Reverse, Full Speed |

| External Control | 0-10KHz, 0-5V, 0-10V, 4-20mA, RS485, Footswitch |

| External Functions | Start/Stop Control, Direction Control, Speed Control |

| Number of Rollers | 3 |

| Working Environment | Temperature 0-40°C, Humidity <80% (non-condensing) |

| Protection Class | IP31 |

| Net Weight | 2.6 KG |

| Product Dimensions | 290 x 142 x 148 mm |

Principle

The working principle of a peristaltic pump is similar to squeezing a fluid-filled tube with your fingers. As the drive motor turns the rollers in the pump head, the rollers alternately compress and release the pump tubing. Under the roller's compression, a 'pillow' of fluid is formed in the tube. As the roller rotates, this pillow of fluid moves forward. When the roller releases the compression, the tube returns to its original shape due to its elasticity, creating a vacuum that draws in new fluid. This continuous cycle results in a smooth, steady fluid transfer. Since the fluid only comes into contact with the inner wall of the tubing, cross-contamination is avoided.

Procedure

- Install the tubing: Open the pump head, place the appropriate peristaltic pump tubing between the rollers and the housing, then close and secure the pump head.

- Connect the power supply: Connect the power cord to an AC100V to AC250V power outlet.

- Power on and set up: Press the power switch. Use the knob on the panel to set the desired speed.

- Set direction: Use the "Forward/Reverse" key to set the fluid direction as needed.

- Start pumping: Press the "Start/Stop" key to begin operation. The speed can be adjusted at any time with the knob to change the flow rate.

- Full speed purge/prime: Press and hold the "Full Speed" key, and the pump will run at maximum speed, suitable for quickly purging or priming the line.

- Timed operation: Enter timing mode, set the desired duration, and press the start key to begin timed dispensing.

- Stop and power off: After completing the operation, press the "Start/Stop" key to halt the pump, then turn off the power.

Advantages

- Contamination-Free: The fluid only contacts the inner wall of the tubing, not the pump body, ensuring high-purity transfer.

- Simple Maintenance: The only part that requires replacement is the tubing, a quick and easy process that requires no special tools.

- Low Shear Force: Ideal for transferring shear-sensitive fluids, such as live cells and proteins.

- Strong Self-Priming: Can start without priming and can run dry without damaging the pump.

- High Metering Accuracy: Achieves high-precision fluid metering and dispensing by accurately controlling speed and time.

- Reversible Flow: The direction can be easily reversed for fluid suction and drawback.

Our Commitment to Accuracy and Quality

We understand that in research and production, every microliter of precision is critical. Therefore, we commit to:

- Strict Quality Control: Every KT-VSP series peristaltic pump undergoes multiple rigorous performance and safety tests before leaving the factory to ensure its stability and durability.

- Precise Calibration: We guarantee that the product's speed control and timing functions meet the stated technical specifications, providing you with reliable and repeatable results.

- High-Quality Materials: All wetted parts are made of high-quality, corrosion-resistant materials to handle a wide range of chemicals.

Flexible Partnership & Supply Models

We understand that every customer's needs are unique. To that end, we offer:

- Standardized Products: We offer a variety of standard models to meet most common application needs.

- OEM/ODM Customization Services: Our strong R&D team can provide customized solutions based on your specific requirements (e.g., function, appearance, integration).

- Flexible Supply Chain: Whether for a single unit purchase or a batch order, we can provide flexible production and delivery schedules to respond to your needs promptly.

- Technical Support & Partnership: We offer comprehensive technical support and are eager to establish long-term partnerships with system integrators and equipment manufacturers to co-develop innovative fluid solutions.

With its exceptional performance and flexibility, the KT-VSP series of smart variable speed peristaltic pumps provides reliable assurance for your fluid handling solutions.

Trusted by Industry Leaders

4.8 / 5

This pump is a game-changer! The precision and ease of use are unmatched. Highly recommend for any lab.

4.9 / 5

Incredible value for money. The speed control is flawless, and the build quality is top-notch.

4.7 / 5

Delivered faster than expected! The pump’s performance is stellar—perfect for our medical applications.

4.9 / 5

Durable and reliable. The variable speed feature is a lifesaver for our industrial processes.

4.8 / 5

The technology behind this pump is impressive. It’s made our lab work so much more efficient.

4.7 / 5

Love the compact design! It fits perfectly in our workspace and delivers consistent results.

4.9 / 5

The pump’s accuracy is outstanding. It’s become an essential tool in our pharmaceutical research.

4.8 / 5

Easy to maintain and operate. The tubing replacement is a breeze—no downtime!

4.7 / 5

The timing function is precise. Perfect for our environmental monitoring needs.

4.9 / 5

Worth every penny! The pump’s versatility and performance have exceeded our expectations.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Laboratory Vertical Water Circulating Vacuum Pump for Lab Use

Looking for a reliable water circulating vacuum pump for your lab or small-scale industry? Check out our Vertical Water Circulating Vacuum Pump with five taps and a larger air sucking amount, perfect for evaporation, distillation, and more.

Laboratory Benchtop Water Circulating Vacuum Pump for Lab Use

Need a water circulating vacuum pump for your lab or small-scale industry? Our Benchtop Water Circulating Vacuum Pump is perfect for evaporation, distillation, crystallization, and more.

Laboratory Rotary Vane Vacuum Pump for Lab Use

Experience high vacuum pumping speed and stability with our UL-certified Rotary Vane Vacuum Pump. Two-shift gas ballast valve and dual oil protection. Easy maintenance and repair.

Custom PTFE Wafer Holders for Lab and Semiconductor Processing

This is a high-purity, custom-machined PTFE (Teflon) holder, expertly designed for the secure handling and processing of delicate substrates like conductive glass, wafers, and optical components.

Laboratory Test Sieves and Sieving Machines

Precision lab test sieves & sieving machines for accurate particle analysis. Stainless steel, ISO-compliant, 20μm-125mm range. Request specs now!

Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

Efficient Laboratory Disc Rotary Mixer for Precise Sample Mixing, Versatile for Various Applications, DC Motor and Microcomputer Control, Adjustable Speed and Angle.

Twin Screw Extruder Plastic Granulation Machine

Twin screw extruder plastic granulation machine is designed for the mixing and processing experiments of engineering plastics, modified plastics, waste plastics and masterbatches.

Custom PTFE Teflon Parts Manufacturer for Three-Necked Round Bottom Flask

PTFE flask, is a versatile laboratory container made from PTFE, offering exceptional chemical resistance, temperature stability, and non-stick properties. Ideal for handling corrosive substances and high-temperature applications, these flasks are essential in various laboratory procedures, including heating, mixing, and storage of chemicals.

Button Battery Case Gasket for Battery Lab Applications

The gasket prevents the deformation of the internal material, and the spring sheet is conducive to the tight contact inside the battery to prevent loosening.

Vibratory Sieve Shaker Machine Dry Three-Dimensional Vibrating Sieve

The KT-V200 product focuses on solving common sieving tasks in the laboratory. It is suitable for sieving 20g-3kg dry samples.

Metal Disc Electrode Electrochemical Electrode

Elevate your experiments with our Metal Disk Electrode. High-quality, acid and alkali resistant, and customizable to fit your specific needs. Discover our complete models today.

Electrode Fixture for Electrochemical Experiments

Upgrade your experiments with our customizable Electrode Fixtures. High-quality materials, acid and alkali resistant, and safe and durable. Discover our complete models today.

Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

Learn about Cylindrical Resonator MPCVD Machine, the microwave plasma chemical vapor deposition method used for growing diamond gemstones and films in the jewelry and semi-conductor industries. Discover its cost-effective advantages over traditional HPHT methods.

Custom Machined and Molded PTFE Teflon Parts Manufacturer with PTFE Crucible and Lid

PTFE crucibles, made from pure Teflon, offer chemical inertness and resistance from -196°C to 280°C, ensuring compatibility with a wide range of temperatures and chemicals. These crucibles feature machine-finished surfaces for easy cleaning and prevention of contamination, making them ideal for precise laboratory applications.

Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

PTFE mesh sieve is a specialized test sieve designed for particle analysis in various industries, featuring a non-metallic mesh woven from PTFE filament. This synthetic mesh is ideal for applications where metal contamination is a concern . PTFE sieves are crucial for maintaining the integrity of samples in sensitive environments, ensuring accurate and reliable results in particle size distribution analysis.

Custom PTFE Teflon Parts Manufacturer for PTFE Measuring Cylinder 10/50/100ml

PTFE measuring cylinder are a rugged alternative to traditional glass cylinders. They are chemically inert over a wide temperature range (up to 260º C), have excellent corrosion resistance and maintain a low coefficient of friction, ensuring ease of use and cleaning.

Conductive Carbon Fiber Brush for Static Removal and Cleaning

Discover the benefits of using conductive carbon fiber brush for microbial cultivation and electrochemical testing. Improve your anode's performance.

Laboratory Manual Hydraulic Pellet Press for Lab Use

Efficient Manure Lab Hydraulic Press with Safety Cover for sample preparation in material research, pharmacy, and electronic industries. Available in 15T to 60T.

Related Articles

Risk-Proof Your Lab: How to Choose a Vacuum Pump That Avoids Costly Failures

Learn how to choose reliable lab vacuum pumps to avoid costly failures. Assess chemical risks, throughput needs & safety for optimal performance.

The Real Reason Your Sintered Parts Crack (And It’s Not the Furnace)

Stop blaming the furnace. Discover the hidden flaw in powder pressing that causes parts to crack and learn how Cold Isostatic Pressing (CIP) offers a permanent fix.

Beyond Brute Force: The Physics and Psychology of Material Transformation

Explore the synergy of hydraulic pressure and thermal energy, and why precise control over both is the key to creating advanced materials.

The Invisible Architecture of Precision: Mastery Before the Current Flows

Achieve electrochemical accuracy by mastering the four pillars of preparation: rigorous inspection, cleaning, installation, and electrolyte management.

Beyond Brute Force: How Isostatic Pressing Creates Flawless Materials

Explore isostatic pressing, a method using uniform pressure, not brute force, to eliminate microscopic flaws and achieve perfect material density.

Understanding Hot Isostatic Pressing in PVD Sputtering Targets

Explores the role of hot isostatic pressing in enhancing the quality and uniformity of PVD sputtering targets, focusing on manufacturing techniques and benefits.

From Powder to Part: The Strategic Choice Between Wet-Bag and Dry-Bag CIP

A deep dive into wet-bag vs. dry-bag Cold Isostatic Pressing, framing the choice not as technical, but as a strategic manufacturing decision.

Application of Liquid Nitrogen in Food Freezing

Explores the use of liquid nitrogen in food freezing, its advantages, methods, equipment, and safety considerations.

The Geometry of Control: Why Millimeters Dictate Experimental Destiny

In electrochemistry, the difference between success and failure often lies in aperture size. Explore the engineering logic behind Φ 6.2mm and Φ 3.2mm standards.

The Invisible Interface: Why Simple Connections Define Complex Chemistry

In electrochemistry, data integrity relies on the physical interface. Discover why the humble copper tape and gasket seal are the true guardians of your results.

The Choreography of Electrons: Why Precision Demands a Trinity

Precision in coating evaluation isn't about power; it's about separation. Discover why the three-electrode system is the only way to silence electrochemical noise.