PTFE material

Customizable PTFE Wafer Carriers for Semiconductor and Lab Applications

Item Number : PTFE-39

Price varies based on specs and customizations

- Material

- PTFE

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

PTFE flower baskets (Teflon flower baskets) are made of high-purity experimental grade PTFE, with excellent chemical stability, corrosion resistance, sealing and high and low temperature resistance (-180°C to +250°C).

We provide customized services such as PTFE cleaning racks and flower baskets for glass substrates (such as ITO, FTO, silicon wafers, etc.), and provide free design and drawing services based on your description or sketch to ensure that various industry needs are met.

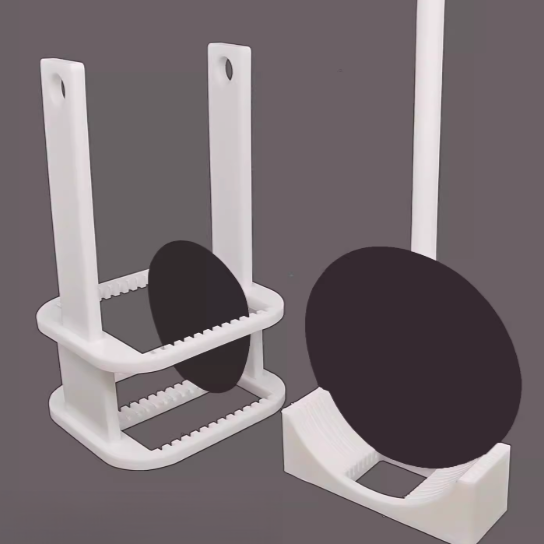

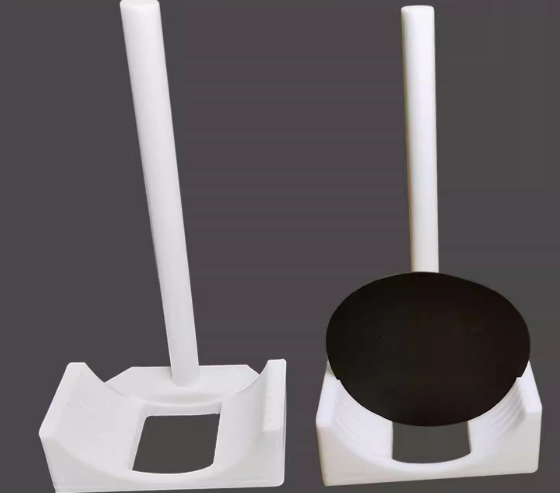

Detail & Parts

Key Advantages

The use of PTFE provides a range of benefits essential for high-technology applications:

- Superior Chemical Resistance: PTFE is virtually inert to most chemicals, including strong acids, bases, and organic solvents used in wafer etching and cleaning processes. This guarantees the carrier will not corrode, degrade, or leach impurities, protecting both the process chemistry and the wafer itself.

- Exceptional Thermal Stability: With a wide operating temperature range (from -200°C to 260°C), these carriers can be used in both heated chemical baths and subsequent rinsing or drying steps without warping or losing structural integrity.

- Ultimate Purity and Non-Contaminating: PTFE is an inherently pure material with an extremely low level of extractables. This prevents the introduction of ionic or organic contaminants onto the wafer surface, which is critical for maximizing device yield and performance.

- Gentle, Non-Abrasive Contact: The material's low coefficient of friction and smooth surface ensure that delicate and highly polished wafer surfaces are not scratched or damaged during handling and processing.

Technical Specifications

| Parameter | Available Sizes |

|---|---|

| Standard Round Sizes | 1", 2", 3", 4", 5", 6", 8", 12" |

| Standard Square Sizes | 4" x 4" (Other custom sizes available upon request) |

Applications

Our PTFE wafer carriers are designed for and trusted in a variety of high-stakes industries:

- Semiconductor Manufacturing: Essential for wet-bench processes such as wafer cleaning (e.g., RCA clean), etching, stripping, and rinsing.

- Research and Development: Ideal for laboratories working with novel materials, MEMS devices, and process development where flexibility and purity are key.

- Photovoltaic (Solar) Cell Production: Used for handling silicon substrates during the texturing and cleaning stages of solar cell manufacturing.

- Medical Device & Optics: Suitable for cleaning and chemical treatment of sensitive glass, quartz, or sapphire components.

Your Partner for Custom Solutions

We understand that standard sizes do not fit every unique application. Our core value lies in our ability to collaborate with clients to design and manufacture fully customized PTFE carriers. Whether you need a specific slot width for a non-standard wafer thickness, a different handle design for robotic automation, or a carrier for square or rectangular substrates, our engineering team is ready to deliver a solution. This bespoke approach ensures a perfect fit for your equipment, enhances process reliability, and protects your high-value assets.

To discuss your unique requirements and begin developing a custom solution that integrates seamlessly into your workflow, please contact us through our inquiry form. Our technical experts are ready to assist you from prototype to full-scale production.

Trusted by Industry Leaders

FAQ

What Is An Ultra Low Temperature Freezer Used For?

What Are Thermal Evaporation Sources?

What Are The Main Types Of Ultra Low Temperature Freezers Available?

What Are The Main Types Of Thermal Evaporation Sources?

What Is Optical Glass Used For?

How Does An Ultra Low Temperature Freezer Work?

How Do Thermal Evaporation Sources Work?

What Is The Composition Of Optical Glass?

What Are The Advantages Of Using An Ultra Low Temperature Freezer?

What Are The Advantages Of Using Thermal Evaporation Sources?

What Are The Most Common Optical Glasses?

What Materials Are Ultra Low Temperature Freezers Typically Made Of?

What Applications Are Thermal Evaporation Sources Used For?

Are Ultra Low Temperature Freezers Energy Efficient?

What Safety Features Do Ultra Low Temperature Freezers Have?

Can Ultra Low Temperature Freezers Be Used For Industrial Applications?

4.9 / 5

Incredible quality and precision! These carriers are a game-changer for our lab workflows.

4.8 / 5

Fast delivery and excellent value. The customization options are top-notch!

4.7 / 5

Durable and reliable. Perfect for high-precision semiconductor applications.

4.9 / 5

Superior craftsmanship! These PTFE carriers exceed expectations every time.

4.8 / 5

Highly customizable and worth every penny. Our lab efficiency has skyrocketed!

4.9 / 5

Flawless performance and durability. A must-have for any advanced lab setup.

4.7 / 5

Quick turnaround and stellar quality. These carriers are a solid investment.

4.8 / 5

Innovative design and robust build. Perfect for demanding semiconductor processes.

4.9 / 5

Exceptional precision and reliability. These carriers have transformed our operations.

4.8 / 5

Outstanding value and performance. The customization is a huge plus!

4.9 / 5

Top-tier quality and fast delivery. These carriers are worth every cent.

4.7 / 5

Reliable and durable. Perfect for high-tech lab environments.

4.8 / 5

Excellent craftsmanship and quick shipping. Highly recommend for precision work.

4.9 / 5

Superior technology and build. These carriers are a lab’s best friend!

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Custom PTFE Teflon Parts Manufacturer for PTFE Bottle Oil Fume Sampling Tube

PTFE products are generally called "non-stick coating", which is a synthetic polymer material that replaces all hydrogen atoms in polyethylene with fluorine.

CF Ultra-High Vacuum Observation Window Window Flange High Borosilicate Glass Sight Glass

Discover CF ultra-high vacuum observation window flanges with high borosilicate glass, perfect for semiconductor manufacturing, vacuum coating, and optical instruments. Clear observation, durable design, easy installation.

Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

PTFE mesh sieve is a specialized test sieve designed for particle analysis in various industries, featuring a non-metallic mesh woven from PTFE filament. This synthetic mesh is ideal for applications where metal contamination is a concern . PTFE sieves are crucial for maintaining the integrity of samples in sensitive environments, ensuring accurate and reliable results in particle size distribution analysis.

1200℃ Muffle Furnace Oven for Laboratory

Upgrade your lab with our 1200℃ Muffle Furnace. Achieve fast, precise heating with Japan alumina fibers and Molybdenum coils. Features TFT touch screen controller for easy programming and data analysis. Order now!

Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

Experience precise melting with our Vacuum Levitation Melting Furnace. Ideal for high melting point metals or alloys, with advanced technology for effective smelting. Order now for high-quality results.

Lab-Scale Vacuum Induction Melting Furnace

Get precise alloy composition with our Vacuum Induction Melting Furnace. Ideal for aerospace, nuclear energy, and electronic industries. Order now for effective smelting and casting of metals and alloys.

Custom Machined and Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

PTFE cleaning racks are mainly made of tetrafluoroethylene. PTFE, known as the "King of Plastics", is a polymer compound made of tetrafluoroethylene.

Vacuum Hot Press Furnace Machine for Lamination and Heating

Experience clean and precise lamination with Vacuum Lamination Press. Perfect for wafer bonding, thin-film transformations, and LCP lamination. Order now!

Custom PTFE Wafer Holders for Lab and Semiconductor Processing

This is a high-purity, custom-machined PTFE (Teflon) holder, expertly designed for the secure handling and processing of delicate substrates like conductive glass, wafers, and optical components.

Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

Zirconia insulating ceramic gasket has high melting point, high resistivity, low thermal expansion coefficient and other properties, making it an important high temperature resistant material, ceramic insulating material and ceramic sunscreen material.

Custom PTFE Teflon Parts Manufacturer for Acid and Alkali Resistant Chemical Powder Material Scoops

Known for its excellent thermal stability, chemical resistance and electrical insulating properties, PTFE is a versatile thermoplastic material.

KF ISO Stainless Steel Vacuum Flange Blind Plate for High Vacuum Systems

Discover KF/ISO stainless steel vacuum flange blind plates, ideal for high vacuum systems in semiconductor, photovoltaic, and research labs. High-quality materials, efficient sealing, and easy installation.<|end▁of▁sentence|>

Non Consumable Vacuum Arc Induction Melting Furnace

Explore the benefits of Non-Consumable Vacuum Arc Furnace with high melting point electrodes. Small, easy to operate & eco-friendly. Ideal for laboratory research on refractory metals & carbides.

Vacuum Bellows for Efficient Connection and Stable Vacuum in High-Performance Systems

Discover high-quality vacuum bellows for stable vacuum in high-performance systems. Made from 304 and 316 stainless steel, these bellows ensure efficient connections and excellent sealing. Ideal for

Infrared Transmission Coating Sapphire Sheet Substrate Window

Crafted from sapphire, the substrate boasts unparalleled chemical, optical, and physical properties. Its remarkable resistance to thermal shocks, high temperatures, sand erosion, and water sets it apart.

High Performance Lab Homogenizer for Pharma Cosmetics and Food R&D

Lab vacuum homogenizing emulsifier for pharmaceuticals, cosmetics & food. High-shear mixing, vacuum deaeration, scalable 1L-10L. Get expert advice now!

Custom PTFE Teflon Parts Manufacturer for PTFE Stirring Bar Recovery Rod

This product is used for stirrer recovery, and is resistant to high temperature, corrosion, and strong alkali, and is almost insoluble in all solvents. The product has a stainless steel rod inside and a polytetrafluoroethylene sleeve outside.

Button Battery Case Gasket for Battery Lab Applications

The gasket prevents the deformation of the internal material, and the spring sheet is conducive to the tight contact inside the battery to prevent loosening.

Laboratory Rotary Vane Vacuum Pump for Lab Use

Experience high vacuum pumping speed and stability with our UL-certified Rotary Vane Vacuum Pump. Two-shift gas ballast valve and dual oil protection. Easy maintenance and repair.

Related Articles

How to Select the Right Oil-Free Diaphragm Pump for Your Lab or Industrial Needs

Learn how to choose the right oil-free diaphragm pump for your lab or industry—balancing specs, chemical resistance, and lifetime costs.

The Thermodynamics of a Perfect Seal: A Component-Level Approach to Sterilization

Learn why autoclaving your entire electrolytic cell destroys the seal. A guide to understanding material properties and protecting your experiments.

The Invisible Variable: Why Cell Maintenance Defines Electrochemical Truth

Data fidelity begins at the sink. Discover the systematic approach to cleaning electrolytic cells and why the integrity of your glassware defines your results.