homogenizer

High Performance Lab Homogenizer for Pharma Cosmetics and Food R&D

Item Number : KT-VHE

Price varies based on specs and customizations

- Homogenizing Speed Range

- 8000~30000rpm

- Processing Viscosity

- 100000~150000CP

- Achievable Vacuum

- -0.098MPa

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

Our laboratory vacuum homogenizing emulsifier is a state-of-the-art system engineered for the complex demands of modern research and development. It provides a comprehensive solution for homogenization, emulsification, dispersion, and mixing processes, meeting the stringent standards of the pharmaceutical, biotechnology, cosmetic, food, and chemical industries. By combining high-shear homogenization with effective mixing under a controlled vacuum environment, this equipment empowers scientists and engineers to achieve superior product quality, stability, and consistency.

This system is designed for versatility, handling everything from low-viscosity liquids to high-viscosity creams and pastes, ensuring reliable and repeatable results from initial formulation to pilot-scale production.

Key Features and Advantages

High-Efficiency Homogenizing and Mixing

- High-Speed Shear: The top-mounted homogenizer reaches speeds of up to 30,000 rpm, creating intense shearing forces to produce extremely fine and stable emulsions and dispersions with a uniform particle size.

- Dual-Action Agitation: A low-speed anchor stirrer, complete with flexible PTFE scraper blades, operates concurrently. This ensures materials are constantly mixed and moved from the vessel walls to the high-shear zone, guaranteeing a homogenous mixture without dead spots, even for materials with viscosity up to 150,000 cP.

Integrated Vacuum System

- Deaeration and Purity: The system can achieve a high vacuum level of -0.098 MPa, effectively removing air bubbles introduced during processing. This prevents oxidation, improves product luster and stability, and is essential for creating high-quality, air-free creams, gels, and suspensions.

Modular and User-Friendly Design

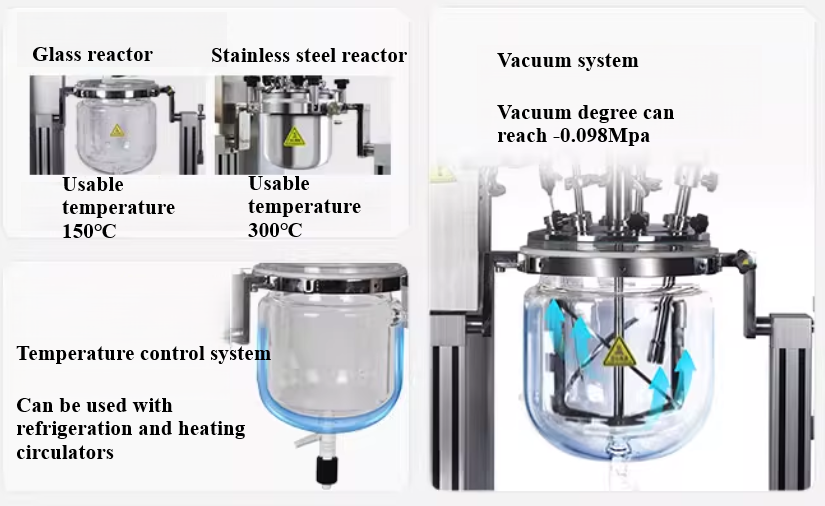

- Flexible Reactor Options: Choose between a high borosilicate glass reactor (up to 150°C) for clear process visibility or a robust 316L stainless steel reactor (up to 300°C) for higher temperature applications and enhanced durability.

- Scalable Volumes: With available capacities from 1L to 10L, the system supports your needs from small-scale R&D experiments to pilot batch production.

- Convenient Operation: The reactor head features a motorized lifting mechanism for effortless access to the vessel for cleaning and material handling. The multi-port lid provides ample connections for a temperature probe, feeding funnel, vacuum line, and other instrumentation.

Precise Process Control

- Superior Temperature Management: The jacketed vessel design allows for seamless integration with external heating or cooling circulators, giving you precise control over the reaction temperature to protect sensitive ingredients and optimize process outcomes.

- Durable Sealing: The homogenizer head is engineered with a specialized mechanical seal, ensuring long-term operational stability and maintaining a perfect vacuum environment throughout the process.

Detail & Parts

Product Specifications

KT-VHE Series (Glass Reactor)

| Parameter | KT-VHE-1 | KT-VHE-2 | KT-VHE-5 | KT-VHE-10 |

|---|---|---|---|---|

| Stirring Volume | 100–1000ml | 100–2000ml | 500–5000ml | 1000–10000ml |

| Stirring Speed Range | 0–230rpm | 0–230rpm | 0–230rpm | 0–230rpm |

| Stirring Paddle Style | SUS316L anchor-type with PTFE wall scraper | |||

| Processing Viscosity | 100000CP | 100000CP | 100000CP | 150000CP |

| Stirring Power | 120W | 150W | 150W | 300W |

| Emulsification Volume | 500–1000ml | 600–2000ml | 2500–5000ml | 5000–10000ml |

| Homogenizing Speed Range | 8000–28000rpm | 8000–28000rpm | 8000–30000rpm | 8000–30000rpm |

| Homogenizer Head Model | 20DG | 25DG | 25DG | 25DG |

| Homogenizer Power | 1300W | 1300W | 1300W | 1300W |

| Reactor Lid Ports | Stirring, Vacuum, Homogenizer, Feeding, Temp. Probe + 3 Spare Ports | |||

| Lifting Stroke | 300mm | 300mm | 500mm | 500mm |

| Max. Working Temp. | 120°C | 120°C | 120°C | 120°C |

| Achievable Vacuum | -0.098MPa | -0.098MPa | -0.098MPa | -0.098MPa |

| Power Supply | AC220V 50Hz | AC220V 50Hz | AC220V 50Hz | AC220V 50Hz |

| Net Weight | 35kg | 40kg | 50kg | 55kg |

| Dimensions (L×W×H) | 400×650×1100 mm | 400×650×1100 mm | 600×450×1100 mm | 600×480×1200 mm |

KT-VHE-S Series (Stainless Steel Reactor)

| Parameter | KT-VHE-1S | KT-VHE-2S | KT-VHE-5S | KT-VHE-10S |

|---|---|---|---|---|

| Stirring Volume | 100–1000ml | 100–2000ml | 500–5000ml | 1000–10000ml |

| Stirring Speed Range | 0–230rpm | 0–230rpm | 0–230rpm | 0–230rpm |

| Stirring Paddle Style | SUS316L anchor-type with PTFE wall scraper | |||

| Processing Viscosity | 100000CP | 100000CP | 100000CP | 150000CP |

| Stirring Power | 120W | 150W | 150W | 300W |

| Emulsification Volume | 500–1000ml | 600–2000ml | 2500–5000ml | 5000–10000ml |

| Homogenizing Speed Range | 8000–28000rpm | 8000–28000rpm | 8000–30000rpm | 8000–30000rpm |

| Homogenizer Head Model | 20DG | 25DG | 25DG | 25DG |

| Homogenizer Power | 1300W | 1300W | 1300W | 1300W |

| Reactor Material | 316L Stainless Steel | |||

| Reactor Lid Ports | Stirring, Vacuum, Homogenizer, Feeding, Temp. Probe + 3 Spare Ports | |||

| Lifting Stroke | 300mm | 300mm | 500mm | 500mm |

| Max. Working Temp. | 120°C | 120°C | 120°C | 120°C |

| Achievable Vacuum | -0.098MPa | -0.098MPa | -0.098MPa | -0.098MPa |

| Power Supply | AC220V 50Hz | AC220V 50Hz | AC220V 50Hz | AC220V 50Hz |

| Net Weight | 35kg | 40kg | 50kg | 55kg |

| Dimensions (L×W×H) | 400×650×1100 mm | 400×650×1100 mm | 600×450×1100 mm | 600×480×1200 mm |

Your Value: From Concept to Production

Investing in our laboratory vacuum emulsifier translates directly into enhanced productivity and innovation. You gain the ability to produce highly stable, professional-grade formulations with exceptional repeatability. The system's scalability ensures a smooth transition from lab-scale formulation to larger production volumes, saving time and resources. Its robust construction and high-quality components (SUS316L, PTFE) guarantee a long service life and reliable performance.

Whether you are developing a new cosmetic cream, formulating a pharmaceutical suspension, or creating a novel food emulsion, our laboratory vacuum emulsifier provides the control and performance you need. To discuss your specific application and find the perfect configuration for your lab, contact our technical specialists today.

Warnings

Operator safety is the top important issue! Please operate the equipment with cautions. Working with inflammable& explosive or toxic gases is very dangerous, operators must take all necessary precautions before starting the equipment. Working with positive pressure inside the reactors or chambers is dangerous, operator must fellow the safety procedures strictly. Extra caution must also be taken when operating with air-reactive materials, especially under vacuum. A leak can draw air into the apparatus and cause a violent reaction to occur.

Designed for You

KinTek provide deep custom made service and equipment to worldwide customers, our specialized teamwork and rich experienced engineers are capable to undertake the custom tailoring hardware and software equipment requirements, and help our customer to build up the exclusive and personalized equipment and solution!

Would you please drop your ideas to us, our engineers are ready for you now!

Trusted by Industry Leaders

FAQ

What Is A Test Sieve?

What Is A Homogenizer And What Are Its Main Applications?

What Is A Steam Sterilizer?

What Are The Main Applications Of Test Sieves?

What Are The Different Types Of Homogenizers Available?

How Does A Steam Sterilizer Work?

How Does A Test Sieve Work?

How Does A Homogenizer Work?

What Are Some Common Applications Of Steam Sterilizers?

What Are The Different Types Of Test Sieves?

What Are The Advantages Of Using A Homogenizer In Laboratory Settings?

How Long Does A Typical Steam Sterilizer Cycle Take?

What Are The Advantages Of Using A Test Sieve?

Can You Explain The Application Of Homogenizers In Microbial Inactivation?

Can Steam Sterilization Be Validated For Effectiveness?

Can Test Sieves Be Used For Both Dry And Wet Samples?

How Does Homogenization Affect The Quality Of Milk?

Can Steam Sterilization Damage Certain Materials?

What Is A PTFE Mesh Sieve, And Where Is It Used?

4.9 / 5

This homogenizer is a game-changer! Super efficient and perfect for our lab needs.

4.8 / 5

Fast delivery and top-notch quality. Worth every penny!

4.7 / 5

Incredibly durable and easy to use. Highly recommend for any lab.

4.9 / 5

The speed and precision of this homogenizer are unmatched. Love it!

4.8 / 5

Perfect for our cosmetics R&D. Saves so much time and effort.

4.9 / 5

High-tech and reliable. A must-have for any serious lab.

4.7 / 5

Great value for money. Works flawlessly every time.

4.8 / 5

Superb performance and very durable. Exceeded our expectations.

4.9 / 5

The best homogenizer we've ever used. Fast, efficient, and reliable.

4.8 / 5

Perfect for pharmaceutical applications. Highly efficient and precise.

4.9 / 5

Amazing product! Delivered quickly and works like a charm.

4.7 / 5

Very impressed with the quality and performance. A great investment.

4.8 / 5

Sleek design and powerful performance. Perfect for our food R&D.

4.9 / 5

Cutting-edge technology. Makes our lab work so much easier.

4.7 / 5

Reliable and efficient. Exactly what we needed for our research.

4.8 / 5

Fantastic product! Delivered on time and works perfectly.

4.9 / 5

Highly recommend! Superb quality and performance.

4.7 / 5

Great for high-throughput labs. Fast and consistent results.

4.8 / 5

Excellent homogenizer. Very pleased with the purchase.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

Enhance lab efficiency with our high-speed Laboratory Emulsifier Homogenizer for precise, stable sample processing. Ideal for pharmaceuticals & cosmetics.

VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

A hydrogen peroxide space sterilizer is a device that uses vaporized hydrogen peroxide to decontaminate enclosed spaces. It kills microorganisms by damaging their cellular components and genetic material.

Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

The desktop fast steam sterilizer is a compact and reliable device used for rapid sterilization of medical, pharmaceutical, and research items. It efficiently sterilizes surgical instruments, glassware, medicines, and resistant materials, making it suitable for various applications.

Desktop Fast High Pressure Laboratory Autoclave Sterilizer 16L 24L for Lab Use

The desktop fast steam sterilizer is a compact and reliable device used for rapid sterilization of medical, pharmaceutical, and research items.

Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

Vertical pressure steam sterilizer is a kind of sterilization equipment with automatic control, which is composed of heating system, microcomputer control system and overheating and overpressure protection system.

Laboratory High Pressure Horizontal Autoclave Steam Sterilizer for Lab Use

The horizontal autoclave steam sterilizer adopts the gravity displacement method to remove the cold air in the inner chamber, so that the inner steam and cold air content is less, and the sterilization is more reliable.

Liquid Nitrogen Cryogenic Grinder Mill Cryomill Airflow Ultrafine Pulverizer

Discover the Liquid Nitrogen Cryogenic Grinding Machine, perfect for lab use, ultra-fine pulverization, and preserving material properties. Ideal for pharmaceuticals, cosmetics, and more.

Lab Sterile Slapping Type Homogenizer for Tissue Mashing and Dispersing

The slapping sterile homogenizer can effectively separate the particles contained in and on the surface of solid samples, ensuring that the mixed samples in the sterile bag are fully representative.

Laboratory Horizontal Autoclave Steam Sterilizer Lab Microcomputer Sterilizer

The horizontal autoclave steam sterilizer adopts the method of gravity displacement to remove the cold air in the inner chamber, so that the content of steam cold air in the inner chamber is less, and the sterilization is more reliable.