It’s a scenario familiar to too many materials engineers and lab managers. After weeks of meticulous work—formulating the powder, setting up the press, and carefully programming the sintering furnace—you open the door to a fresh batch of high-performance components. But instead of the perfect parts you need, you find a collection of cracked, warped, or distorted failures. The project deadline is looming, the costs of wasted material are mounting, and you’re right back where you started.

You think to yourself, "Was the heating rate too fast? Was there a binder issue? Maybe it was a bad batch of powder?" The troubleshooting begins, but the root of the problem remains elusive.

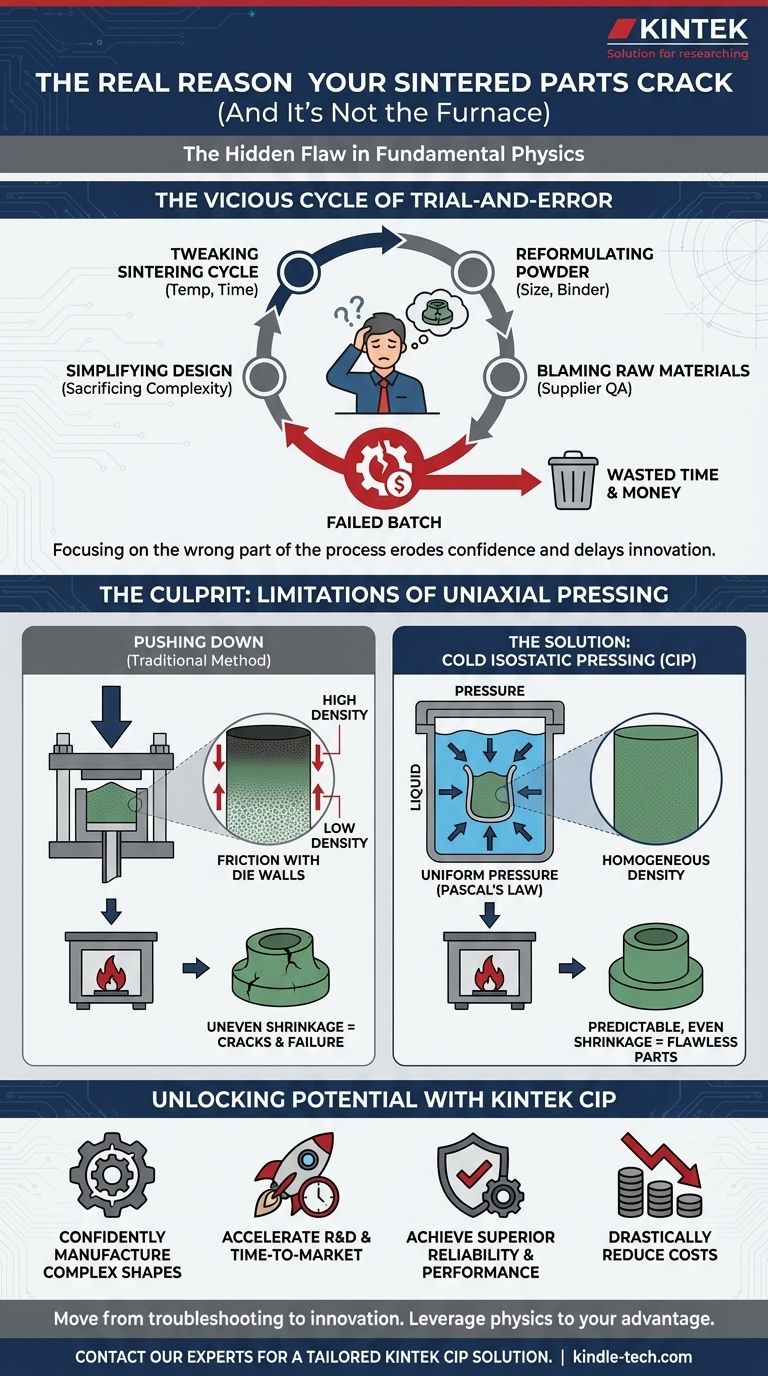

The Vicious Cycle of Trial-and-Error

This isn't an isolated incident; it's a chronic headache in the world of advanced materials. When faced with inconsistent results in producing parts from ceramic, metal, or carbide powders, teams typically find themselves stuck in a costly loop.

You might try:

- Tweaking the sintering cycle: Adjusting temperatures, hold times, and atmospheric conditions.

- Reformulating the powder: Changing particle size, distribution, or binders.

- Blaming the raw materials: Sending samples back to the supplier, questioning their quality control.

- Simplifying the design: Sacrificing component complexity in the hope of achieving a successful outcome.

Each failed attempt doesn't just waste a single batch. It consumes weeks of valuable R&D time, burns through expensive high-purity powders, and racks up energy costs from running the furnace. More importantly, it erodes confidence. It delays product launches, jeopardizes contracts, and forces your team to spend their time firefighting instead of innovating. But what if all of these efforts are focused on the wrong part of the process?

The Culprit Hiding in Plain Sight: A Flaw in Fundamental Physics

The frustrating truth is that in many cases, the fatal flaw was sealed into your component long before it ever entered the furnace. The problem isn't your material or your heat treatment—it's the way the part was first formed.

The Limitation of "Pushing Down"

Most components are formed using a traditional uniaxial press, where a punch compacts powder inside a rigid die by applying pressure from a single direction. It seems straightforward, but this method has a fundamental physical limitation: friction.

As the punch pushes down, friction between the powder particles and the die walls prevents the pressure from distributing evenly. The powder directly under the punch gets compacted densely, but the powder at the bottom and sides of the die receives far less force.

The result is a "green" part (an unfired component) with invisible density gradients—hidden weak spots and internal stresses. When you later heat this non-uniform part in a furnace, these different-density zones shrink at different rates. That uneven shrinkage is what causes the cracking, warping, and failure that has been derailing your work.

This is why adjusting the furnace often fails. You’re trying to fix a deep, structural problem with a surface-level solution. It's like trying to fix a house's cracked foundation by applying a new coat of paint.

Fighting Physics with Physics: The Isostatic Pressing Solution

To create a flawless final component, you must first create a flawless green part. This requires a method that overcomes the physical limitations of uniaxial pressing. You need a way to apply pressure not from one direction, but from all directions simultaneously.

This is precisely what Cold Isostatic Pressing (CIP) was engineered to do.

Instead of a rigid die, CIP uses a flexible, sealed mold filled with your powder. This mold is submerged in a chamber of liquid, and a pump pressurizes the liquid. Based on a fundamental principle of physics (Pascal's Law), that pressure is transmitted instantly and equally to every single point on the mold's surface.

Imagine squeezing a snowball in your cupped hands. The pressure comes from all sides, creating a uniformly dense sphere. That’s the principle of CIP. It compacts the powder homogenously, completely eliminating the density gradients and internal stresses that plague uniaxially pressed parts.

A component formed with CIP enters the furnace as a perfectly uniform mass. When heated, it shrinks predictably and evenly, without the internal conflicts that lead to failure. Our KINTEK CIP systems are designed as a direct answer to this challenge. They aren't just another piece of equipment; they are a tool built on a deep understanding of powder mechanics, enabling you to produce green parts that are structurally sound from their very core.

From Troubleshooting to Innovation: What's Possible Now?

When you eliminate the root cause of inconsistent part quality, you do more than just solve a production problem. You unlock new potential for your entire operation.

With a reliable CIP process, your team can finally:

- Confidently manufacture complex shapes: Produce intricate geometries, large components, or parts with high aspect ratios that were previously impossible to make without defects.

- Accelerate R&D and time-to-market: Stop wasting weeks on troubleshooting and redirect that valuable engineering time toward developing new materials and next-generation products.

- Achieve superior reliability and performance: Manufacture high-performance components—like wear-resistant tools or advanced ceramic insulators—with the near-perfect structural integrity your customers demand.

- Drastically reduce costs: Slash the budget wasted on scrapped high-value powders, failed furnace runs, and endless quality control cycles.

By moving beyond the limitations of traditional pressing, you transform your lab from a place of constant troubleshooting into a hub of genuine innovation.

Your challenges are unique, from the materials you use to the components you aim to create. Instead of fighting against the physics of powder compaction, it's time to leverage it to your advantage. Our team can help you analyze your current process, identify the true source of failure, and determine how a tailored CIP solution can help you achieve your project goals faster and more reliably. Let's discuss what's holding you back and how we can help you move forward. Contact Our Experts.

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

Related Articles

- Sample preparation and unloading method of electric tablet press

- Lab Scale Mini Tablet Press: Applications, Processes, and Features

- The working process of the tablet press you should know

- Innovative tableting solutions: a comprehensive analysis of laboratory single punch tablet presses

- Fully automatic tablet press operating steps and replacement accessories