Electric Lab Press

Electric button battery sealing machine

Item Number : PP2N

Price varies based on specs and customizations

- Pressure range

- 50-1500kg

- Pressure-holding time

- 0-999 seconds

- Sealing mold

- Optional CR16, CR20, CR24, CR30, etc.

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Introduction

The electric button battery sealer is a high-performance packaging equipment designed for mass production of button batteries (such as CR series, LR series, SR series, etc.), suitable for electronic manufacturing, new energy research and development, and industrial automation production lines. The equipment is driven by an electric servo system, combined with intelligent pressure control and precision molds, and can quickly complete the precise pressing and sealing of the battery shell to ensure the internal airtightness, leakage prevention and long-term stability of the battery. Its automated operation, high compatibility and low failure rate make it the preferred equipment for medium and large battery manufacturers, OEM factories and high-end laboratories to improve production capacity and yield.

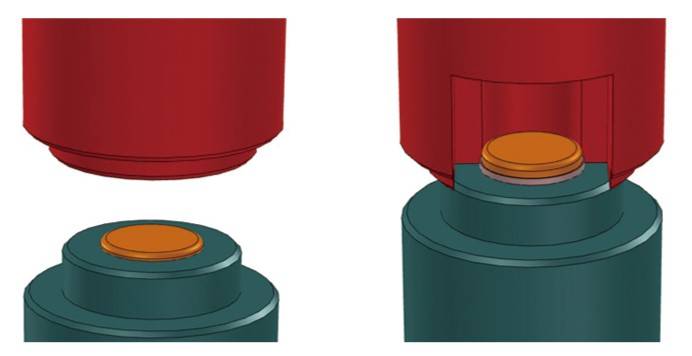

Detail & Parts

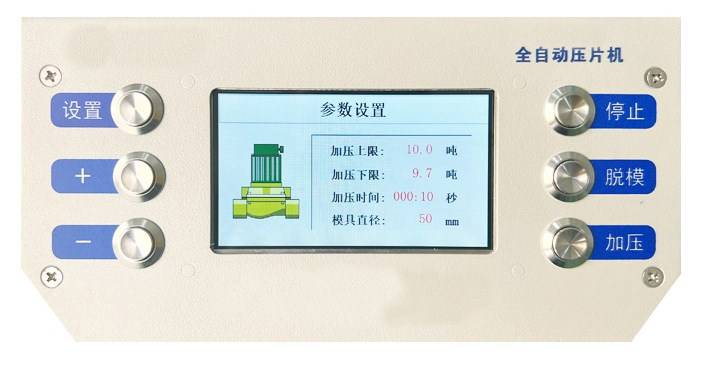

- Setting: In the operation interface, press the setting button to enter the setting interface and then press the setting button to move the setting content. After moving to the mold diameter, press the setting button again to return to the operation interface. (Note: When the time is set to "0", it means that the setting time is infinite.)

- +: In the operation interface, press the "+" key to increase the setting number

- -: In the operation interface, press the "-" key to reduce the setting number

- Stop: When the equipment is running, press the "Stop" button, the equipment will stop the motor and open the pressure relief valve to release the pressure

- Demolding: Press the "Demolding" button, the equipment will start, when the pressure exceeds the specified pressure, or contact the limit switch, the equipment will automatically stop and release the pressure, or you can stop the operation manually.

- Sample preparation: Press the "Sample preparation" button, the equipment will start, when the pressure reaches the set pressure, stop pressurization and time the pressure maintenance, automatically add pressure when it is lower than the lower limit of pressurization, and automatically release pressure after the timing ends.

Application

Electric button battery sealing machines are widely used in the following scenarios:

- Consumer electronics: mass production and packaging of button batteries for smart watches, Bluetooth headsets, calculators and other devices.

- Medical health: production of micro batteries for hearing aids, portable monitors, implantable medical devices, etc.

- Industrial Internet of Things: battery assembly for low-power devices such as wireless sensors, RFID tags, smart cards, etc.

- New energy research and development: pilot and large-scale production of new button batteries such as lithium-manganese batteries and zinc-air batteries.

Features

- Fully automatic operation, efficient and labor-saving

- Adopting electric servo drive system, one-button start can complete the whole process of feeding, positioning and pressing, with a production efficiency of 300-600 pieces/hour, supporting continuous operation.

- Equipped with touch screen or CNC panel, parameters (pressure, time, stroke) can be adjusted visually to reduce the need for manual intervention.

- Precision pressure control technology

- Built-in high-precision pressure sensor, supports 0.1-10kN stepless adjustment, error range ≤±1%, ensuring uniform force and sealing consistency of battery shells of different materials.

- The mold is made of imported alloy steel with hardness ≥HRC60, suitable for various button batteries with diameters of 5-30mm, and supports rapid mold replacement.

- Intelligent safety protection

- Equipped with photoelectric sensing system and emergency brake switch, it automatically stops when abnormal vibration or accidental touch, and complies with CE/UL industrial safety certification.

- The fully enclosed protective cover design avoids metal debris splashing and ensures the safety of operators.

- Low energy consumption and long life

- The energy consumption of servo motors is 40% lower than that of traditional pneumatic equipment, which is energy-saving and environmentally friendly.

- The core components are designed to be wear-resistant, with a theoretical service life of more than 500,000 times, and the maintenance cost is only 1/3 of the industry average.

Advantages

- 1. Significantly improve production efficiency

- The automated process is 5-8 times more efficient than the manual sealing machine.

- Ultra-high yield rate and consistency

- The intelligent pressure feedback system eliminates overpressure or underpressure problems, and the finished product has a high airtightness pass rate, which significantly reduces rework and material waste.

- Flexible adaptation to multiple scene requirements

- Optional vibration plate automatic feeding and assembly line online module, seamless connection to intelligent manufacturing production line, support for non-standard mold customization and development.

- High long-term return on investment

- The equipment has strong stability, failure rate

Technical specifications

| Instrument model | PP2N |

|---|---|

| Pressure range | 50-1500kg |

| Pressure-adding process | Program pressurization - program pressure maintenance - timed pressure release |

| Pressure-holding time | 0-999 seconds |

| Pressure conversion | Program automatically converts the pressure that the mold can withstand |

| LCD display | 4.3-inch LCD screen |

| Sealing mold | Optional CR16, CR20, CR24, CR30, etc. |

| Shell removal mold | Optional CR16, CR20, CR24, CR30, etc. |

| Standard mold | Standard CR20 series packaging mold |

| Dimensions | 220*240*380(L*W*H) |

| Equipment power supply | 220V(50Hz/60Hz) |

| Equipment weight | 35kg |

| Machine size diagram |  |

Operation steps

1. Turn on the power of the automatic sealing machine.

2. Press the setting button to enter the setting menu.

3. Adjust the maximum pressure and holding time, etc.

4. Put the button battery shell into the mold.

5. Press the start button to start the sealing process.

6 The system pressurizes to the set pressure and starts to hold the pressure.

7. The equipment completes the sealing and automatically releases the pressure.

8. Take out the sealed battery shell.

Trusted by Industry Leaders

4.9 / 5

Incredible machine! Boosted our production and the precision is unmatched. A worthy investment. Highly recommended!

4.8 / 5

Superb quality and performance! Easy to use interface and extremely reliable. This has streamlined our battery production.

4.7 / 5

Excellent sealing machine. The consistency and speed are impressive. Minimal downtime and easy maintenance.

4.9 / 5

A fantastic piece of engineering. The precision and safety features are top-notch. A great addition to our lab.

4.8 / 5

Great value for money. This sealing machine is efficient and durable. The automation has significantly reduced labor costs.

4.7 / 5

High-quality machine. The pressure control is very accurate. Easy to set up and operate. Very satisfied!

4.9 / 5

Impressed with the speed and accuracy. The machine is built to last. Excellent support from the Kintek team.

4.8 / 5

This sealing machine is a game-changer! Increased our output and reduced waste. A must-have for battery manufacturers.

4.7 / 5

Reliable and efficient. The electric servo system is a major upgrade. Highly recommend for mass production.

4.9 / 5

The automatic operation is fantastic. Saves time and labor. Worth every penny. A top-tier product.

4.8 / 5

Excellent product! The precision and consistency are remarkable. Easy to maintain and operate. A great investment.

4.7 / 5

Super efficient! The machine is very stable and reliable. Great for high-volume production. Highly recommended.

4.9 / 5

Fantastic machine! Very easy to use, and the results are consistent. A must-have for any battery production facility.

4.8 / 5

Great performance and durability! The pressure control is very precise. Significant improvement in our production process.

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Button Battery Tablet Press Sealing Mold for Lab Use

The sealing die is essential for assembling button batteries, ensuring components like the anode, cathode, and electrolyte are securely enclosed.

Manual button battery sealing machine (digital display)

The manual button battery sealing machine is a small device specially used for button battery packaging. It is easy to operate and suitable for laboratories and small batch production to ensure that the battery is firmly sealed and improve production efficiency.

Button Battery Disassembly and Sealing Mold for Lab Use

The simple sealing and disassembly mold can be directly used on ordinary tablet presses, which can save costs, is convenient and fast, and can be used to encapsulate and disassemble button batteries. Other specifications can be customized.

Manual button battery sealing machine

The manual button battery sealing machine is a high-precision packaging device designed specifically for small button batteries (such as CR2032, LR44 and other models). It is suitable for laboratory research and development, small batch production and teaching demonstrations.

Button Battery Case for Battery Lab Applications

Button batteries are also known as micro batteries. It looks like a small button-shaped battery. Usually larger in diameter and thinner in thickness.

Button Battery Case Gasket for Battery Lab Applications

The gasket prevents the deformation of the internal material, and the spring sheet is conducive to the tight contact inside the battery to prevent loosening.

Laboratory Hydraulic Press Lab Pellet Press for Button Battery

Efficiently prepare samples with our 2T Button Battery Press. Ideal for material research labs and small-scale production. Small footprint, lightweight, and vacuum-compatible.

Button Battery Storage Box for Battery Lab

Button-type battery storage box, detachable, high-quality PP environmental protection material; suitable for small objects/chemicals, etc., thickened, compressive, durable, and available in a variety of styles.

Nickel Aluminum Tabs for Soft Pack Lithium Batteries

Nickel tabs are used to manufacture cylindrical and pouch batteries, and positive aluminum and negative nickel are used to produce lithium-ion and nickel batteries.

Battery Lab Equipment 304 Stainless Steel Strip Foil 20um Thick for Battery Test

304 is a versatile stainless steel, which is widely used in the production of equipment and parts that require good overall performance (corrosion resistance and formability).

Hydrophilic Carbon Paper TGPH060 for Battery Lab Applications

Toray carbon paper is a porous C/C composite material product (composite material of carbon fiber and carbon) that has undergone high-temperature heat treatment.

Polyethylene Separator for Lithium Battery

The polyethylene separator is a key component of lithium-ion batteries, located between the positive and negative electrodes. They allow the passage of lithium ions while inhibiting electron transport. The performance of the separator affects the capacity, cycle and safety of the battery.

Battery Lab Equipment Battery Capacity and Comprehensive Tester

The scope of application of the battery comprehensive tester can be tested: 18650 and other cylindrical, square lithium batteries, polymer batteries, nickel-cadmium batteries, nickel-metal hydride batteries, lead-acid batteries, etc.

Cylindrical Battery Steel Case for Battery Lab

Lithium-ion battery casing suppresses battery polarization, reduces thermal effects, and improves rate performance.

CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

Discover high-vacuum CF/KF flange electrode feedthroughs, ideal for vacuum systems. Superior sealing, excellent conductivity, and customizable options.

Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

Efficiently calcine and dry bulk powder and lump fluid materials with an electric heating rotary furnace. Ideal for processing lithium ion battery materials and more.

Platinum Sheet Electrode for Battery Lab Applications

Platinum sheet is composed of platinum, which is also one of the refractory metals. It is soft and can be forged, rolled and drawn into rod, wire, plate, tube and wire.

Cylindrical Lab Electric Heating Press Mold for Laboratory Applications

Efficiently prepare samples with Cylindrical Lab Electric Heating Press Mold. Fast heating, high temp & easy operation. Custom sizes available. Perfect for battery, ceramic & biochemical research.

Related Articles

The Invisible Variable: Why Electrolytic Cell Hygiene Defines Your Data

Proper electrolytic cell maintenance prevents dangerous reactions and ensures data integrity. Learn the critical "no metal brush" rule and safety protocols.

The Architecture of Silence: Why Quartz Defines Electrochemical Precision

In electrochemistry, the vessel is as critical as the catalyst. Discover why quartz's unique properties make it the unseen hero of precise experimentation.