An effective autoclave maintenance schedule is a multi-layered plan, not a single checklist. It involves daily operator checks for cleanliness, weekly tests for efficacy, and more intensive monthly, quarterly, and annual inspections of core components like safety valves, heating coils, and steam traps performed by trained personnel. This tiered approach is the only way to ensure consistent sterilization, operator safety, and equipment longevity.

The core principle of autoclave maintenance is shifting from a reactive "fix-it-when-it-breaks" mindset to a proactive, scheduled strategy. Consistent, preventative care is non-negotiable for ensuring safety, compliance, and the operational integrity of your sterilization process.

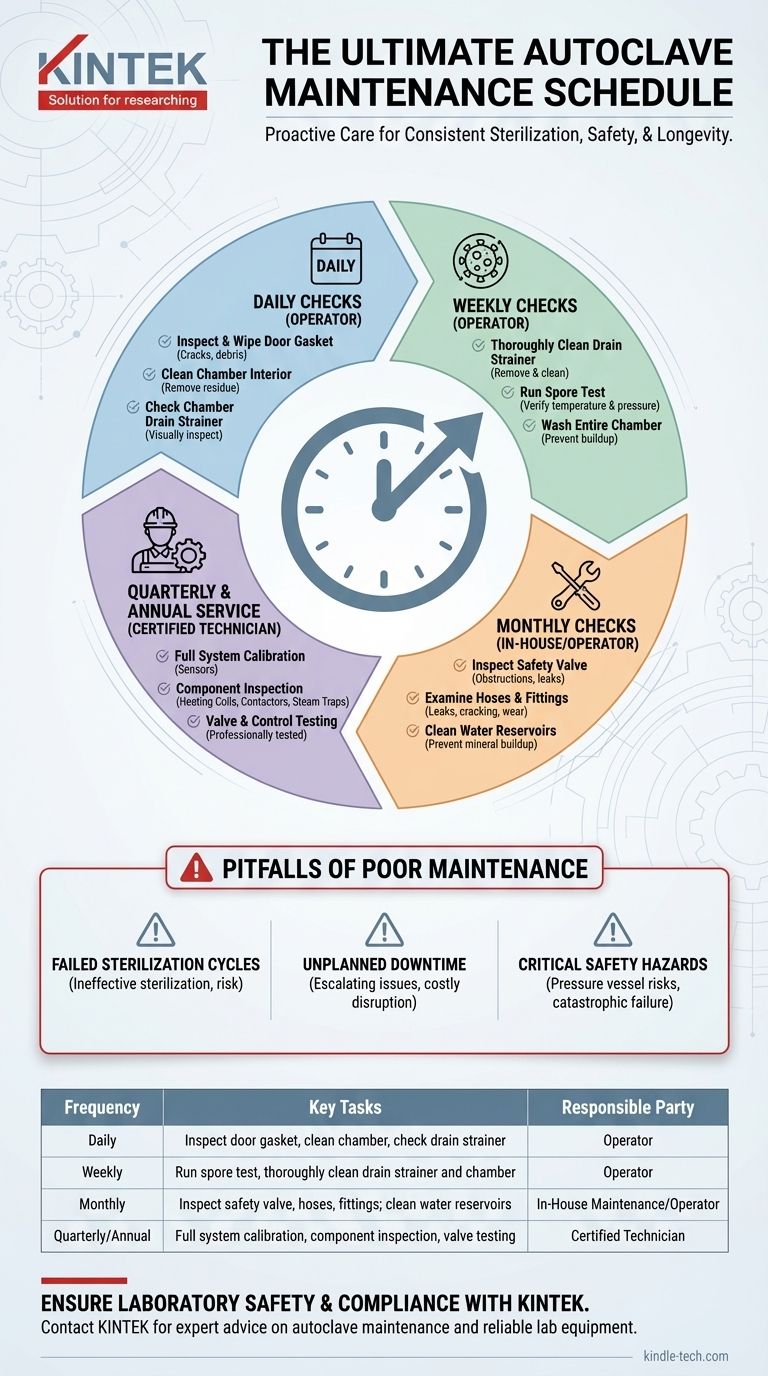

The Multi-Tiered Maintenance Schedule

An autoclave is a high-performance machine that operates under extreme pressure and temperature. Its maintenance schedule is divided into tasks for the daily user and more in-depth inspections for trained technicians.

Daily Checks (Operator Responsibility)

These simple tasks take only a few minutes but are your first line of defense against common failures.

- Inspect and Wipe the Door Gasket: Check the silicone gasket for any cracks or debris and wipe it clean with a damp, lint-free cloth. A clean gasket is critical for creating a perfect seal.

- Clean the Chamber Interior: After the chamber has cooled, wipe down the interior surfaces to remove any residue from previous cycles. This prevents cross-contamination and buildup.

- Check the Chamber Drain Strainer: Visually inspect the drain strainer at the bottom of the chamber. Remove any debris like tape or gauze that could cause a clog.

Weekly Checks (Operator Responsibility)

Weekly tasks focus on verifying the autoclave's performance and ensuring drains remain clear.

- Thoroughly Clean the Drain Strainer: Remove the strainer and clean it thoroughly with a mild detergent. A clogged drain can lead to standing water, wet packs, and aborted cycles.

- Run a Spore Test: Use a biological indicator (spore test) to verify that the autoclave is achieving the necessary temperature and pressure to kill highly resistant microorganisms. This is the ultimate proof of effective sterilization.

- Wash the Entire Chamber: Following the manufacturer's instructions, wash the chamber and racking system to prevent the buildup of residue that can spot or damage instruments.

Monthly Checks (In-House Maintenance or Operator)

These checks delve slightly deeper into the machine's core functions.

- Inspect the Safety Valve: Visually check the pressure relief valve to ensure it is not obstructed or leaking. If your protocol allows, perform a manual check by gently pulling the lever to release a small burst of steam, confirming it isn't stuck.

- Examine Hoses and Fittings: Look for any signs of leaks, cracking, or wear on all external water and steam connections.

- Clean Water Reservoirs: If your autoclave has a water reservoir for steam generation, clean it according to the manufacturer's guidelines to prevent mineral buildup.

Quarterly and Annual Service (Certified Technician)

These essential tasks must be performed by a qualified technician with specialized tools and knowledge.

- Full System Calibration: A technician will calibrate temperature and pressure sensors to ensure the readings on the screen are accurate. Inaccurate sensors can lead to failed sterilization.

- Component Inspection: Key components like heating coils, electrical contactors, and steam traps are inspected for wear and proper function. These are critical for generating and controlling the steam.

- Valve and Control Testing: All valves, including the safety valve, are professionally tested to ensure they function correctly under pressure. Controls and software may also be updated.

Understanding the Pitfalls of Poor Maintenance

Ignoring a consistent maintenance schedule introduces significant and unnecessary risks that extend far beyond simple inconvenience.

Failed Sterilization Cycles

The most immediate consequence is ineffective sterilization. A small leak in a gasket or a miscalibrated sensor can mean that instruments you believe are sterile are, in fact, not, posing a severe risk in medical or research settings.

Unplanned Downtime

Minor issues, like a partially clogged drain or mineral buildup, inevitably escalate. These lead to aborted cycles, emergency service calls, and costly downtime that disrupts your entire workflow.

Critical Safety Hazards

An autoclave is a pressure vessel. Neglecting the safety valve, door-locking mechanisms, or pressure sensors creates a genuine risk of a catastrophic failure, which could result in severe injury to personnel and damage to your facility.

How to Apply This to Your Facility

Your specific needs will shape how you apply this schedule, but the principles remain universal.

- If your primary focus is regulatory compliance and patient safety: Prioritize rigorous documentation of all daily tasks and biological testing, and never postpone scheduled service by a certified technician.

- If your primary focus is equipment longevity and minimizing costs: Emphasize the daily and weekly cleaning duties, as preventing residue and mineral buildup is the single best way to avoid premature component failure.

Ultimately, viewing your autoclave maintenance schedule as a core operational process—not an afterthought—is the key to ensuring safe, reliable, and effective sterilization.

Summary Table:

| Frequency | Key Tasks | Responsible Party |

|---|---|---|

| Daily | Inspect door gasket, clean chamber, check drain strainer | Operator |

| Weekly | Run spore test, thoroughly clean drain strainer and chamber | Operator |

| Monthly | Inspect safety valve, hoses, fittings; clean water reservoirs | In-House Maintenance / Operator |

| Quarterly/Annual | Full system calibration, component inspection (heating coils, steam traps), valve testing | Certified Technician |

Ensure your laboratory's safety and compliance with a reliable autoclave. Proper maintenance is non-negotiable for effective sterilization. KINTEK specializes in high-quality lab equipment and consumables, serving all your laboratory needs. Let our experts help you establish a proactive maintenance plan to protect your investment and ensure uninterrupted workflows.

Contact KINTEK today for expert advice and support on autoclave maintenance and reliable laboratory equipment!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- What is the primary function of a laboratory autoclave in the pre-treatment of medical plastic waste for liquid fuel?

- What is the primary function and principle of autoclaving? Master Lab Sterilization with High-Pressure Steam

- What is the function of laboratory autoclaves in SCWR research? Predict Material Compatibility and Corrosion Kinetics

- What critical environmental conditions does a laboratory autoclave provide for evaluating wear resistance? - KINTEK

- What role do laboratory autoclaves play in pectin extraction? Optimize Prebiotic Yield from Citrus and Apple Biomass