Multilayer co-extrusion is an advanced manufacturing process where multiple, distinct molten polymers are combined into a single, layered structure. Using a series of extruders, the individual materials are melted and then precisely merged in a specialized component called a feedblock or a multi-manifold die before being shaped into their final form.

The fundamental goal of co-extrusion is not simply to combine plastics, but to engineer a composite material that possesses a combination of properties—such as barrier, strength, and cost-effectiveness—that no single polymer could achieve on its own.

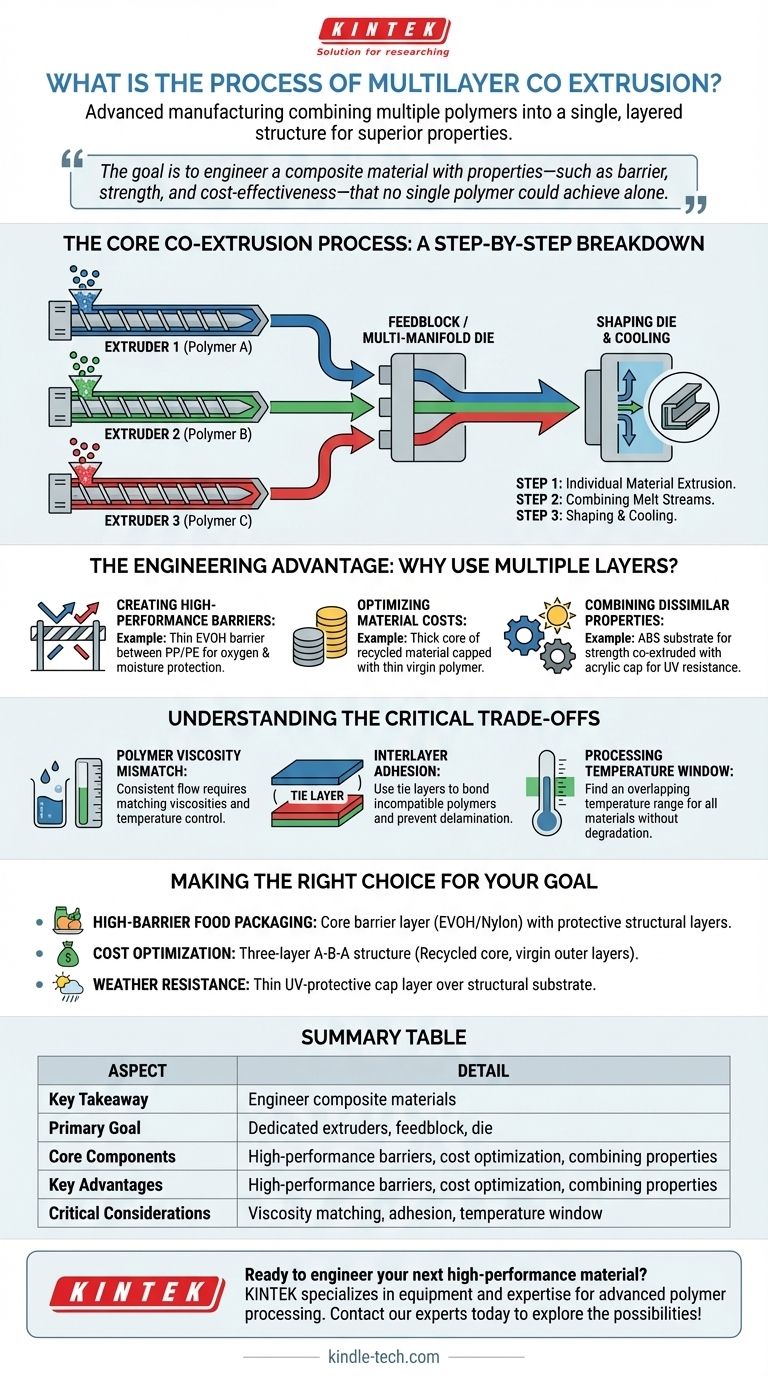

The Core Co-extrusion Process: A Step-by-Step Breakdown

To understand how co-extrusion works, it's best to visualize the journey of the materials through the production line. The process is a seamless flow from raw material to a complex, finished profile.

Step 1: Individual Material Extrusion

Each unique polymer used in the final structure begins in its own dedicated extruder. An extruder is essentially a heated barrel containing a rotating screw.

Raw polymer, typically in the form of pellets, is fed into the barrel. The combination of heat from the barrel and the shear force from the turning screw melts the plastic into a homogenous, high-pressure fluid.

Step 2: Combining the Melt Streams

This is the critical step where the "co-extrusion" happens. The separate molten streams from each extruder are guided into a central feedblock.

The feedblock contains precision-engineered channels that arrange the individual polymer streams into a specific layered sequence. It merges them into a single, multi-layered flow without allowing them to mix.

Step 3: Shaping the Final Product in the Die

The combined, layered melt stream exits the feedblock and enters the shaping die. The die's internal geometry forces the material into its final profile, such as a thin film, a sheet, or a tube.

As the material passes through the die, the layers are compressed, ensuring a strong bond is formed between them. It is then cooled rapidly to solidify the structure and lock the layers into place.

The Engineering Advantage: Why Use Multiple Layers?

The complexity of co-extrusion is justified by its ability to create highly optimized materials that solve specific engineering challenges.

Creating High-Performance Barriers

Many packaging applications require a barrier to oxygen, moisture, or chemicals to protect the contents. Materials like EVOH (Ethylene Vinyl Alcohol) are excellent gas barriers but are often expensive and sensitive to moisture.

Co-extrusion allows a micro-thin layer of EVOH to be sandwiched between thicker, moisture-resistant, and structural layers like polypropylene (PP) or polyethylene (PE).

Optimizing Material Costs

Manufacturers can significantly reduce costs by using a multi-layer structure. For example, a product can be designed with a thick core layer made of less expensive recycled material.

This core is then capped on both sides with thin layers of virgin polymer to provide a pristine surface finish, color, and required performance characteristics.

Combining Dissimilar Properties

A single product can be engineered for multiple functions. A common example is outdoor-rated materials, which may feature a structural substrate like ABS (Acrylonitrile Butadiene Styrene) co-extruded with a thin cap layer of acrylic (PMMA).

The ABS provides impact strength and rigidity, while the acrylic cap layer provides excellent UV resistance and weatherability, preventing the ABS from degrading in sunlight.

Understanding the Critical Trade-offs

Co-extrusion is a powerful but demanding process. Success depends on carefully managing the interaction between different polymers under high heat and pressure.

Polymer Viscosity Mismatch

The viscosity, or flow resistance, of each molten polymer must be closely matched. If one material flows much more easily than another, the more fluid layer can distort the less fluid one, leading to inconsistent layer thickness or structural defects.

This requires careful material selection and precise temperature control for each individual extruder.

Interlayer Adhesion

Many dissimilar polymers will not naturally bond to each other, a problem known as poor adhesion. If the layers don't stick together, the final product can delaminate and fail under stress.

To overcome this, a "tie layer" is often required. This is a thin intermediate layer of a specialized adhesive polymer that is engineered to bond to the two incompatible layers on either side of it.

Processing Temperature Window

Each polymer has an ideal processing temperature range. In co-extrusion, you must find an overlapping temperature window where all materials can be processed effectively without any one of them degrading from excessive heat.

This constraint can limit the possible combinations of materials that can be successfully co-extruded.

Making the Right Choice for Your Goal

Your application's primary requirement will dictate the ideal material structure.

- If your primary focus is high-barrier food packaging: Your design must include a core barrier layer (like EVOH or nylon) protected by structural layers (like PP or PE) and bonded with the appropriate tie layers.

- If your primary focus is cost optimization: A three-layer A-B-A structure, where the "B" core is a lower-cost regrind or recycled material and the "A" outer layers are virgin polymer, is the most effective approach.

- If your primary focus is weather resistance for outdoor products: You must co-extrude a thin, protective cap layer containing UV inhibitors and pigments over a more economical and structural substrate.

By understanding these core principles, you can effectively leverage multilayer co-extrusion to engineer materials with precisely tailored performance characteristics.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Primary Goal | Engineer a composite material with properties no single polymer can achieve. |

| Core Components | Dedicated extruders, feedblock/multi-manifold die, shaping die. |

| Key Advantages | High-performance barriers, material cost optimization, combination of dissimilar properties. |

| Critical Considerations | Polymer viscosity matching, interlayer adhesion, processing temperature window. |

Ready to engineer your next high-performance material? The multilayer co-extrusion process is key to creating products with superior barrier properties, optimized costs, and combined material strengths. KINTEK specializes in providing the equipment and expertise for advanced polymer processing, serving laboratories and manufacturers in developing innovative composite materials. Let's discuss how co-extrusion can solve your specific material challenges. Contact our experts today to explore the possibilities!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Anti-Cracking Press Mold for Lab Use

- Laboratory Test Sieves and Sieving Machines

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Three-dimensional electromagnetic sieving instrument

People Also Ask

- What is a two roll mill? Master Polymer Mixing for R&D and Quality Control

- What size are injection molding machines? Match Tonnage to Your Part for Quality & Efficiency

- What are the advantages of blown film extrusion? Boost Your Film Production Efficiency

- Why is the dynamic mixing mode necessary for high-strength HPE-CSPE? Unlock Superior Elastomer Performance

- What are the different types of powder mixers? Choose the Right Mixer for Your Materials

- What are the advantages of dual extruders? Unlock Multi-Material and Soluble Support Printing

- What is a vulcanizing press? Essential Tool for Rubber Manufacturing and Tire Production

- Is co-extrusion the same as dual extrusion? Unlock the Power of Multi-Material Plastic Profiles