In short, THC distillate is created through a multi-stage refinement process. It begins with a crude cannabis extract which is then purified through winterization to remove fats and waxes. The crucial final step is short path distillation, which uses carefully controlled heat and vacuum pressure to isolate the THC molecules from nearly all other plant compounds, resulting in an exceptionally pure and potent oil.

The core principle behind creating THC distillate is not about extraction, but about purification. It's a systematic process of stripping away everything that isn't THC, molecule by molecule, until you are left with a clear, flavorless, and highly concentrated final product.

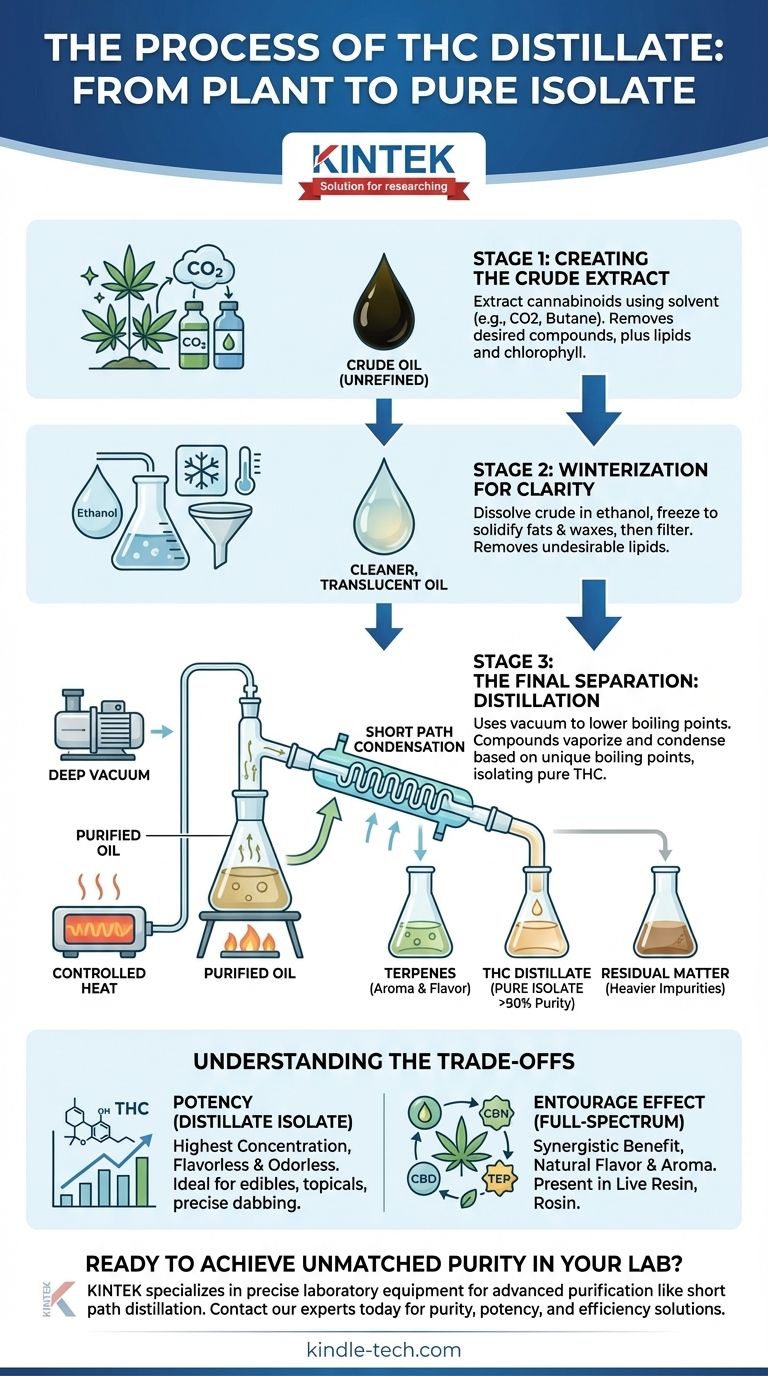

The Journey from Plant to Pure Cannabinoid

Creating distillate is a technical process that mirrors other industrial refining methods, like purifying crude oil into gasoline. Each step is designed to remove a specific set of impurities, bringing the final product closer to pure THC.

Stage 1: Creating the Crude Extract

Before any purification can begin, cannabinoids must be extracted from the raw plant material. This creates a thick, dark, and unrefined "crude oil."

This initial step is typically done using a solvent like CO2 or a hydrocarbon (like butane). The goal here is simply to get the desired compounds out of the plant, along with many other substances like lipids, chlorophyll, and waxes.

Stage 2: Winterization for Clarity

The crude oil is not yet suitable for distillation because it contains fats, waxes, and other lipids that would contaminate the final product. The next step, winterization, removes them.

The crude extract is dissolved in ethanol and then frozen for 24-48 hours. The extreme cold causes the undesirable fats and waxes to solidify and separate, allowing them to be filtered out. The result is a much cleaner, more translucent oil.

Stage 3: The Final Separation: Distillation

This is the most critical and defining step in the process, where the THC is finally isolated. This is achieved using a method called short path distillation.

The Role of Vacuum and Heat

Cannabinoids like THC have very high boiling points—so high that direct heat would destroy them before they could vaporize. To solve this, the entire system is placed under a deep vacuum.

Lowering the pressure inside the distillation apparatus dramatically lowers the boiling point of all the compounds. This allows the THC to be gently vaporized at a safe temperature, preserving its integrity.

Separating by Boiling Point

Inside the distillation unit, the purified oil is slowly heated. As the temperature rises, different compounds turn into vapor based on their unique boiling points.

First, the more volatile compounds like terpenes (which provide aroma and flavor) are boiled off and collected separately. As the temperature increases further, the THC begins to vaporize. This THC vapor rises a very short distance (hence "short path") before it hits a cooled surface and condenses back into a liquid, where it is collected.

The Result: A Pure Isolate

Heavier materials with higher boiling points, such as residual plant matter, chlorophyll, and other minor cannabinoids, are left behind. The final product is a thick, clear or light-amber oil that is almost entirely pure THC.

Understanding the Trade-offs

While distillate offers unparalleled purity and potency, this refinement process involves clear compromises that are important to understand.

The Loss of Natural Flavor and Aroma

The distillation process systematically removes the plant's natural terpenes. These compounds are responsible for the distinct scent and flavor profiles of different cannabis strains. The resulting distillate is inherently flavorless and odorless.

Many manufacturers address this by reintroducing terpenes (either cannabis-derived or botanically-derived) back into the final product to create specific flavors and effects.

Potency vs. The "Entourage Effect"

Distillate is a THC isolate. This means it lacks the broad spectrum of other cannabinoids (like CBD, CBN, CBG) and terpenes that are present in the original plant.

Many believe these compounds work together synergistically in what is known as the "entourage effect," where the combined effect is greater than the sum of its parts. By isolating THC, you gain potency but lose this potential synergistic benefit.

How to Apply This to Your Goal

Understanding the process helps you choose the right product for your intended experience.

- If your primary focus is maximum potency and versatility: THC distillate is the ideal choice due to its high concentration and lack of flavor, making it suitable for edibles, topicals, or precise dabbing.

- If your primary focus is a natural, full-plant experience: You may prefer "full-spectrum" extracts like live resin or rosin, which preserve the natural terpenes and minor cannabinoids.

- If your primary focus is a balance of potency and flavor: Look for distillates that have been infused with cannabis-derived terpenes, which aim to replicate a specific strain's profile on a highly potent base.

Ultimately, the creation of THC distillate is a testament to the power of scientific refinement, designed to produce one specific molecule in its purest form.

Summary Table:

| Stage | Process | Purpose | Key Outcome |

|---|---|---|---|

| 1 | Crude Extraction | Remove cannabinoids from plant material | Dark, unrefined crude oil |

| 2 | Winterization | Remove fats, waxes, and lipids | Cleaner, translucent oil |

| 3 | Short Path Distillation | Isolate THC using heat and vacuum | Clear, highly potent THC distillate (>90% purity) |

Ready to Achieve Unmatched Purity in Your Lab?

KINTEK specializes in the precise laboratory equipment and consumables essential for advanced purification processes like short path distillation. Whether you are developing cannabinoid isolates, pharmaceuticals, or other high-purity compounds, our systems deliver the controlled heat and vacuum pressure required for exceptional results.

Contact our experts today to discuss how KINTEK can support your laboratory's specific needs for purity, potency, and efficiency.

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Evaporation Crucible for Organic Matter

- Multi-Punch Rotary Tablet Press Mold Ring for Rotating Oval and Square Molds

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

People Also Ask

- What happens during sintering of ceramics? A Guide to Transforming Powder into Dense, Strong Parts

- What is the voltage of DC sputtering? Harness High Voltage for Efficient Metal Deposition

- Does hardening increase tensile strength? Boost Material Strength for Demanding Applications

- What is extruded graphite used for? Cost-Effective Conductivity for Industrial Processes

- How should steel be heated during heat treatment? Master the 3 Stages for Perfect Results

- What types of biological materials can be safely stored at -70C? A Guide to Long-Term Sample Preservation

- What temperature should Rotavap be? Master the Delta 20 Rule for Safe, Efficient Solvent Removal

- What is the most commonly used in semiconductors? Discover Why Silicon Dominates Modern Electronics