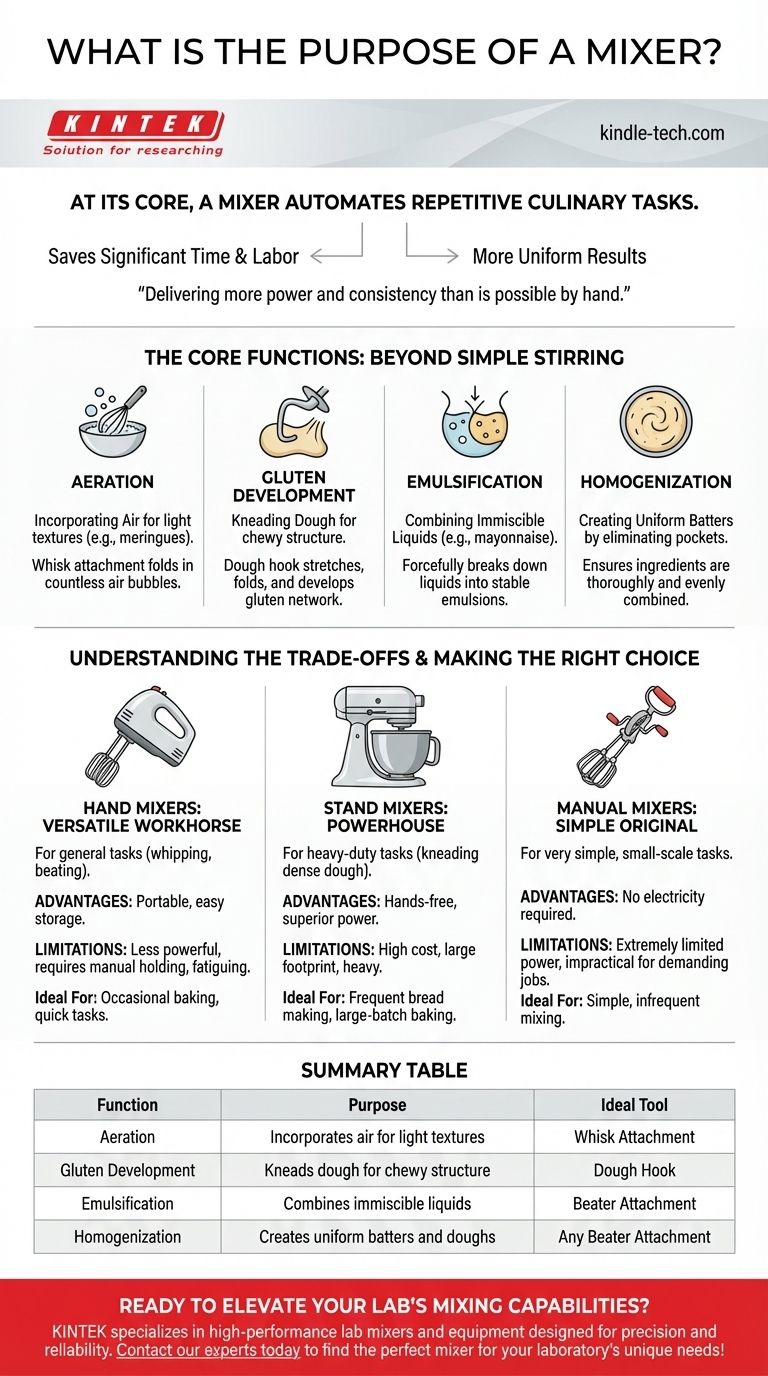

At its core, a mixer is a tool designed to automate repetitive culinary tasks. Its fundamental purpose is to replace the manual effort of stirring, whisking, beating, and kneading ingredients, delivering more power and consistency than is possible by hand. This automation saves significant time and labor while producing more uniform results.

A mixer’s value extends far beyond simple stirring. Its true purpose is to perform specific mechanical actions—like forcing air into liquids, developing gluten in dough, or creating stable emulsions—with a level of efficiency and control that is often the key to a successful recipe.

The Core Functions: Beyond Simple Stirring

While a mixer combines ingredients, its primary functions are more technical. It manipulates the physical and chemical structure of your food in ways that are difficult to replicate manually.

Aeration: Incorporating Air

Many recipes, from meringues to whipped cream, depend on aeration. A mixer's whisk attachment is designed to rapidly whip liquids, folding in countless microscopic air bubbles. This process increases volume and creates a light, airy texture that is structurally essential for certain desserts.

Gluten Development: Kneading Dough

For bread making, the mixer's dough hook is a game-changer. It mimics the motion of hand-kneading by stretching, folding, and developing the gluten network within the dough. Proper gluten development is what gives bread its characteristic chewy structure and ability to rise.

Emulsification: Combining Immiscible Liquids

An emulsion is a mixture of two liquids that don't normally combine, like oil and water. A mixer creates stable emulsions, such as mayonnaise or certain salad dressings, by forcefully breaking down one liquid into tiny droplets and dispersing them evenly throughout the other.

Homogenization: Creating Uniform Batters

The most basic function is ensuring all ingredients are thoroughly and evenly combined. For cake batters or cookie dough, a mixer eliminates pockets of dry flour or clumps of butter, leading to a consistent final product.

Understanding the Trade-offs

The "best" mixer is entirely dependent on the task. Different designs offer distinct advantages and come with inherent limitations. Understanding these trade-offs is key to choosing the right tool.

Hand Mixers: The Versatile Workhorse

A handheld motorized mixer is the most common type. Its beaters are effective for general-purpose tasks like whipping cream, beating eggs, or mixing cake batters.

Their main advantage is portability and ease of storage. However, they are less powerful than stand mixers and require you to hold and guide the unit, which can be fatiguing for longer tasks.

Stand Mixers: The Powerhouse for Heavy Duty Tasks

A stand mixer features a powerful, stationary motor and a bowl that locks into place. This hands-free design, combined with superior power, makes it the ideal tool for heavy or time-consuming jobs.

It excels at kneading dense bread doughs and mixing large batches. The primary downsides are its high cost, large countertop footprint, and significant weight.

Manual Mixers: The Simple Original

The classic "eggbeater" is a hand-cranked device. It requires no electricity and is useful for very simple, small-scale tasks.

Its utility is extremely limited by its lack of power. While functional for whipping a single egg white or a small amount of cream, it is impractical for anything more demanding.

Making the Right Choice for Your Goal

The best mixer for you is the one that aligns with your specific cooking and baking habits.

- If your primary focus is occasional baking and quick tasks: A quality hand mixer offers the best balance of utility, cost, and easy storage.

- If your primary focus is frequent bread making or large-batch baking: A stand mixer is a necessary investment for its superior power and hands-free operation.

- If your primary focus is simple, infrequent mixing: A manual eggbeater is a minimalist tool that can handle basic jobs without electricity or taking up space.

Ultimately, selecting the right mixer is about empowering your process to achieve better and more consistent results.

Summary Table:

| Function | Purpose | Ideal Tool |

|---|---|---|

| Aeration | Incorporates air for light textures (e.g., meringues) | Whisk Attachment |

| Gluten Development | Kneads dough for chewy, well-risen bread | Dough Hook |

| Emulsification | Combines immiscible liquids (e.g., mayonnaise) | Beater Attachment |

| Homogenization | Creates uniform batters and doughs | Any Beater Attachment |

Ready to elevate your lab's mixing capabilities? KINTEK specializes in high-performance lab mixers and equipment designed for precision and reliability. Whether you need consistent homogenization for samples or powerful emulsification for reagents, our solutions save you time and ensure reproducible results. Contact our experts today to find the perfect mixer for your laboratory's unique needs!

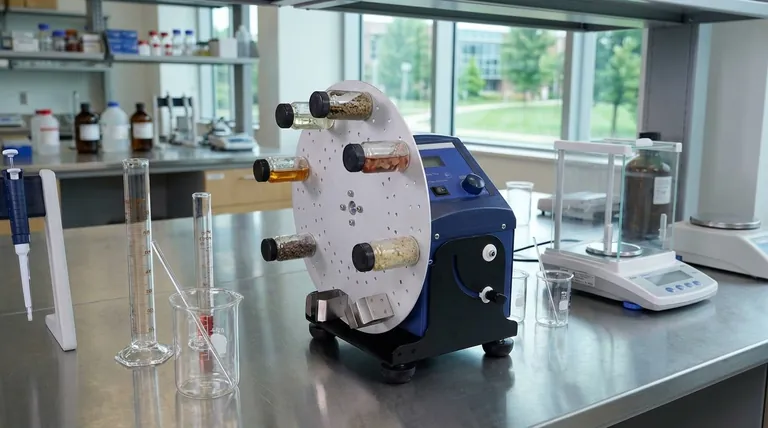

Visual Guide

Related Products

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Single Horizontal Jar Mill

- Laboratory Test Sieves and Sieving Machines

- Laboratory Vibratory Sieve Shaker Machine Slap Vibrating Sieve

- High Energy Vibratory Laboratory Ball Mill Double Tank Type

People Also Ask

- Why you should avoid water contamination when performing FTIR measurements using NaCl or KBr plates? Protect Your Equipment & Data Integrity

- What is the effect of pyrolysis temperature on bio-oil? Optimize Yield and Quality for Your Lab

- What are the alternatives to plastic waste management? A Guide to Circular Solutions

- What are the five methods used to sterilize materials in a laboratory? A Guide to Matching Method to Material

- What are some examples of inert gases in real life? From Balloons to Welding, Discover Their Uses

- How does a thermostatic shaker improve sugar yield? Maximize Biomass Conversion Efficiency

- What is the purpose of using a glass vacuum desiccator after drying biomass? Ensure Precise Sample Data Integrity

- What is the alternative process to sintering? Compare Casting, Forging & Machining for Your Project