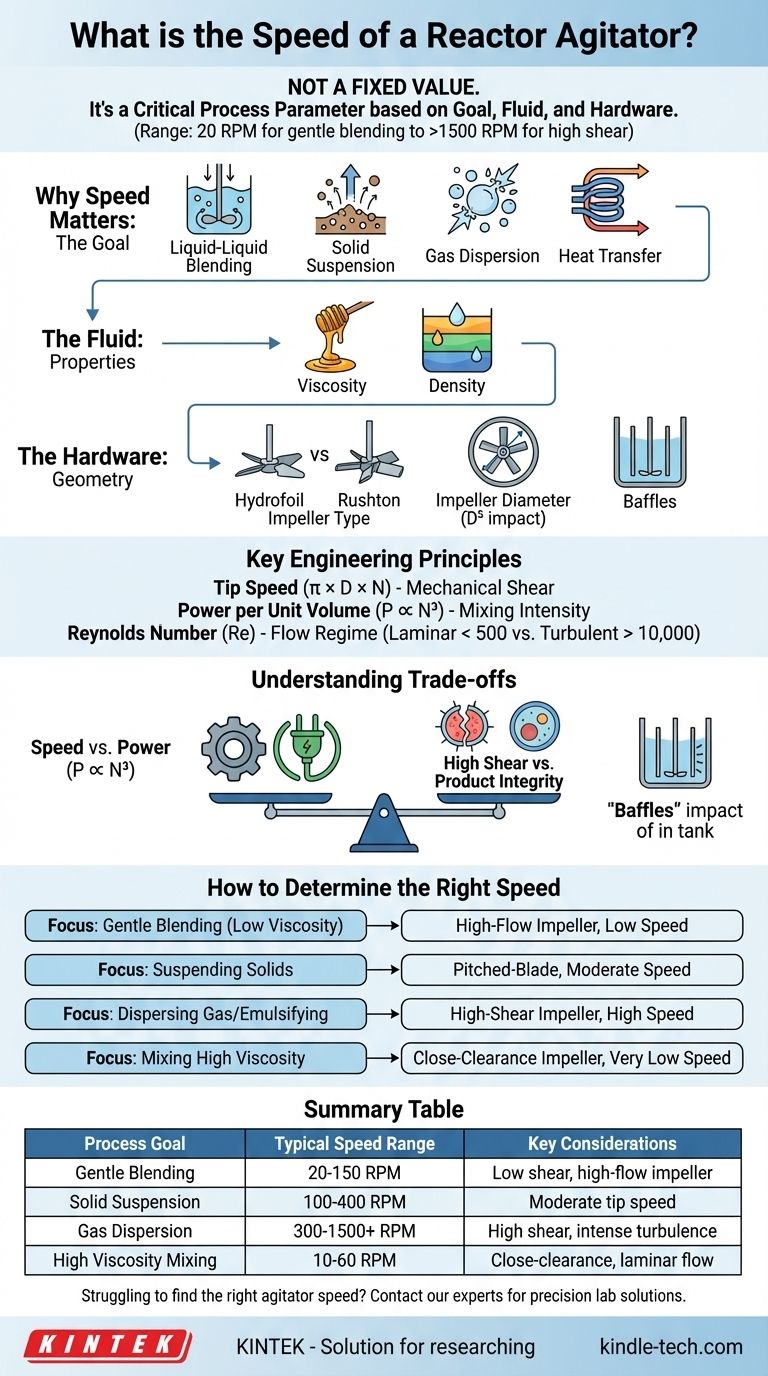

The speed of a reactor agitator is not a single, fixed value. It is a critical process parameter that is deliberately chosen based on the specific goal of the operation. While speeds can range from as low as 20 RPM for large-scale, gentle blending to over 1,500 RPM for high-shear laboratory applications, the correct speed is entirely dependent on the fluid properties, the reactor geometry, and the desired process outcome.

Choosing the right agitator speed isn't about finding a universal number; it's about delivering the precise type and amount of mixing energy required for your specific goal—whether that is blending, suspending solids, transferring heat, or dispersing gas.

Why Speed is a Critical Process Variable

The "speed" in revolutions per minute (RPM) is only part of the story. It is a means to an end. The true goal is to control the physical phenomena inside the vessel, and speed is the primary lever you use to do so.

The Goal: What Are You Trying to Achieve?

The purpose of the agitation dictates the energy required.

-

Liquid-Liquid Blending: The goal is to create a homogenous mixture. This often requires generating enough turbulence to break down concentration gradients throughout the vessel.

-

Solid Suspension: The goal is to lift solid particles off the bottom of the tank and keep them uniformly distributed. This requires significant vertical flow, which is directly tied to speed and impeller design.

-

Gas Dispersion: The goal is to break up large gas bubbles into a cloud of fine bubbles to maximize the surface area for mass transfer. This demands high-speed, high-shear agitation.

-

Heat Transfer: The goal is to move fluid past the vessel walls or internal coils to ensure uniform temperature. Insufficient speed can lead to localized hot or cold spots.

The Fluid: Understanding Its Properties

The substance being mixed is the single most important factor.

-

Viscosity: This is the fluid's resistance to flow. Low-viscosity fluids (like water) are easy to mix and achieve turbulent flow at relatively low speeds. High-viscosity fluids (like syrups or polymers) require very different strategies, often using low speeds with impellers that have a close clearance to the tank wall.

-

Density: The difference in density between liquids or between a liquid and a solid directly impacts the speed needed to create and maintain a stable mixture or suspension.

The Hardware: Impeller and Tank Geometry

The equipment itself defines how the motor's rotational speed is translated into fluid motion.

-

Impeller Type: A high-flow impeller (like a hydrofoil) is designed to move large volumes of fluid efficiently at lower speeds. A high-shear impeller (like a Rushton turbine) is designed to create intense turbulence and break things apart at higher speeds.

-

Impeller Diameter (D): The power an impeller draws is proportional to the diameter to the fifth power (D⁵). A small change in impeller size has a massive impact on the energy input at a given speed.

-

Baffles: These are vertical plates on the tank wall that prevent the entire fluid mass from spinning in a vortex. They are essential for converting rotational motion into effective mixing, allowing for higher speeds without swirling.

Key Engineering Principles That Determine Speed

Engineers don't guess the speed; they use established principles to calculate the target range for a desired outcome.

Tip Speed

Tip speed is the linear velocity at the outermost edge of the impeller. It is a direct measure of the mechanical shear being imparted to the fluid.

It is calculated as: Tip Speed = π × Impeller Diameter × Rotational Speed. This value is critical for shear-sensitive materials, such as biological cells or crystals that can be damaged by excessive speed.

Power per Unit Volume

This metric (W/m³ or hp/1000 gal) represents the intensity of mixing. Different processes have well-established power requirements.

For example, gentle blending might require 0.1 kW/m³, while gas dispersion might demand over 3.0 kW/m³. Since power is proportional to the speed cubed (P ∝ N³), a small increase in speed dramatically increases the power input and mixing intensity.

Reynolds Number (Re)

This dimensionless number helps define the flow regime.

-

Low Re (< 500): This is the laminar regime, common with high-viscosity fluids. The fluid moves in smooth layers, and mixing is achieved by physical folding and contact. Anchor or helical ribbon impellers are used here at low speeds.

-

High Re (> 10,000): This is the turbulent regime, where chaotic eddies are responsible for mixing. Most low-viscosity applications operate here, where turbines and hydrofoils are effective.

Understanding the Trade-offs

Selecting an agitator speed is an exercise in balancing competing factors. There is no "perfect" speed, only an optimal one for a specific set of constraints.

Speed vs. Power Consumption

The relationship between speed and power is cubic (P ∝ N³). Doubling the agitator speed will increase the power consumption by approximately eight times. This is the most significant trade-off and has major implications for operational cost and motor sizing.

High Shear vs. Product Integrity

While high speed and high shear are excellent for dispersion, they can be destructive. For processes involving fragile cells, polymers, or crystals, excessive tip speed can damage or destroy the product, leading to yield loss.

The Impact of Baffles

Operating at high speed without baffles is inefficient. The liquid will simply swirl, creating a deep vortex with poor top-to-bottom mixing. Baffles are necessary to convert this rotational energy into useful mixing, but they also increase the power draw for a given speed.

How to Determine the Right Speed for Your Application

Instead of searching for a single number, focus on your primary objective. This will guide you to the correct combination of speed and impeller type.

- If your primary focus is gentle blending of low-viscosity liquids: Use a high-flow impeller (e.g., hydrofoil) at a low-to-moderate speed to achieve full tank turnover without creating excessive shear.

- If your primary focus is suspending solids: You will need a sufficient tip speed to generate the vertical flow needed to lift particles; this often requires a pitched-blade turbine at a moderate-to-high speed.

- If your primary focus is dispersing gas or emulsifying immiscible liquids: You need a high-shear impeller (e.g., Rushton turbine) operating at a high speed to create the intense turbulence necessary to break up bubbles or droplets.

- If your primary focus is mixing high-viscosity or non-Newtonian fluids: Use a close-clearance impeller (e.g., anchor, helical ribbon) at a very low speed that physically contacts and moves the majority of the batch.

Ultimately, selecting the correct agitator speed is a deliberate engineering decision that directly controls the success and efficiency of your process.

Summary Table:

| Process Goal | Typical Speed Range | Key Considerations |

|---|---|---|

| Gentle Blending | 20 - 150 RPM | Low shear, high-flow impeller |

| Solid Suspension | 100 - 400 RPM | Moderate tip speed for vertical flow |

| Gas Dispersion | 300 - 1500+ RPM | High shear, intense turbulence |

| High Viscosity Mixing | 10 - 60 RPM | Close-clearance impeller, laminar flow |

Struggling to find the right agitator speed for your lab process? KINTEK specializes in precision lab equipment and consumables, offering expert solutions for reactors and mixing systems. Our team can help you select the ideal agitator configuration to achieve perfect blending, suspension, or dispersion—ensuring your experiments are both efficient and reproducible. Contact our experts today to optimize your mixing process and enhance your lab's performance!

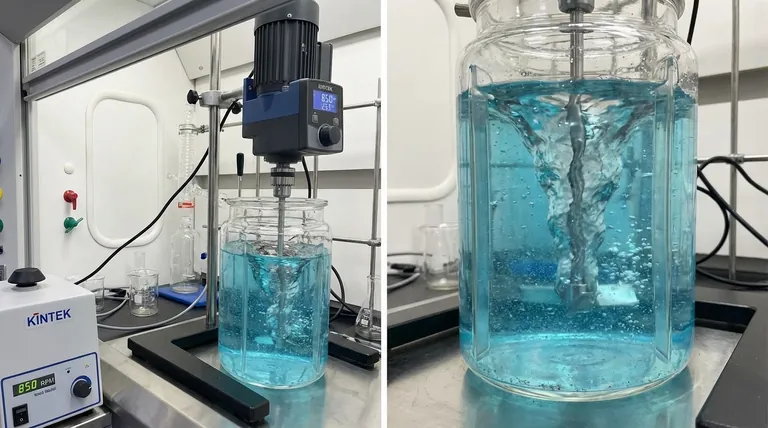

Visual Guide

Related Products

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

- Laboratory Oscillating Orbital Shaker

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Automatic Laboratory Heat Press Machine

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

People Also Ask

- What are the primary functions of a laboratory orbital shaker during BMP testing? Maximize Methane Yield Accuracy

- What is the role of laboratory stirring equipment in nZVI preparation? Achieve Stable and Uniform Nano Slurries

- What is the primary purpose of using an orbital shaker during metal ion adsorption? Optimize PAF Performance

- How does a laboratory stirrer influence MOF product quality? Master Precision in Non-Solvothermal Synthesis

- Why is a high-precision orbital shaker required for chitin adsorption? Achieve Rapid Equilibrium & Precise Data