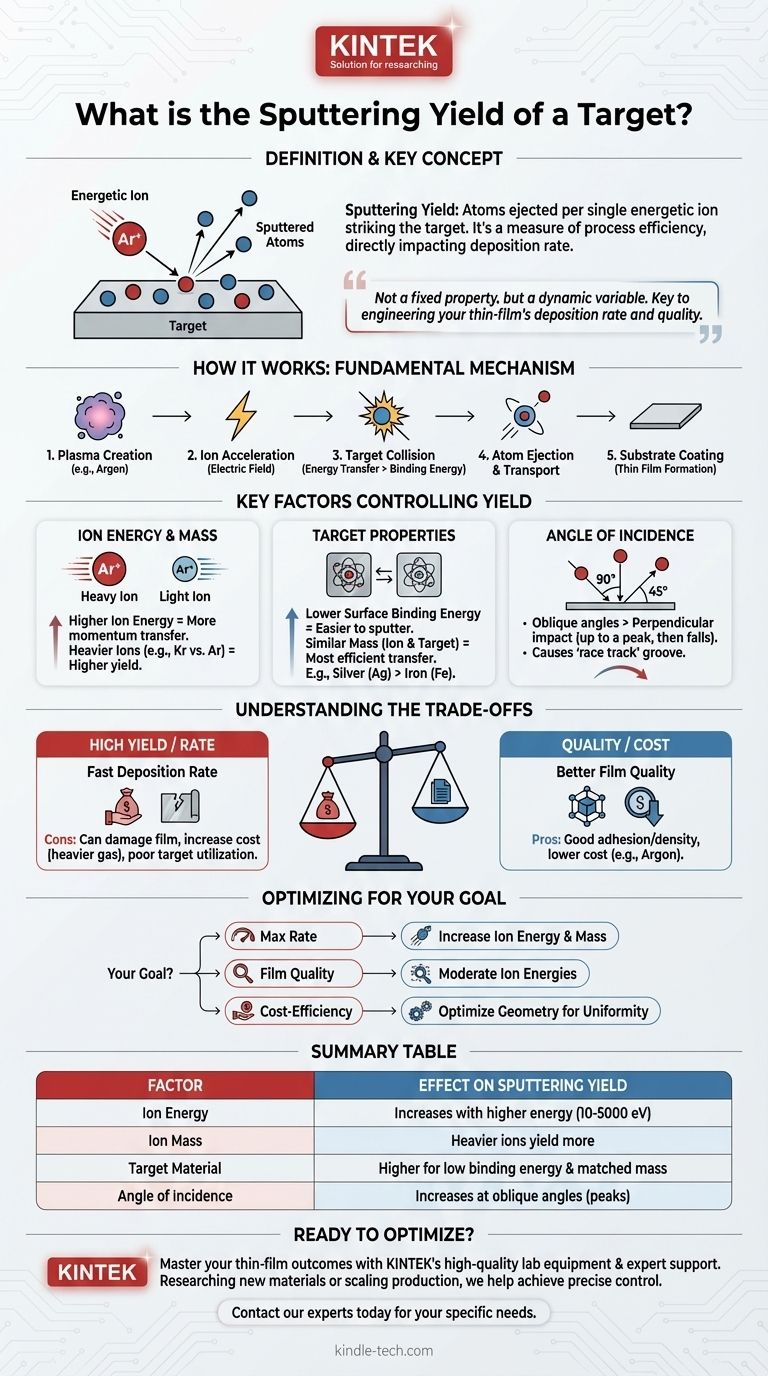

In thin-film deposition, sputtering yield is the single most important measure of process efficiency. It is defined as the number of atoms ejected from a target surface for each single energetic ion that strikes it. A higher yield means more material is removed from the target and made available for coating a substrate, directly influencing the deposition rate.

Sputtering yield is not a fixed property of a material, but a dynamic variable. Understanding the factors that control it is the key to moving from simply running a process to actively engineering your thin-film's deposition rate and final quality.

How Sputtering Yield Works

The Fundamental Mechanism

Sputtering begins by creating a plasma, typically from an inert gas like Argon, inside a vacuum chamber. An electric field accelerates these positively charged Argon ions towards the negatively charged target, which is made of the material you wish to deposit.

When these high-energy ions collide with the target, they transfer kinetic energy to the atoms on the surface. If the energy transferred is greater than the surface binding energy of the target atoms, those atoms are ejected, or "sputtered," away from the target.

These sputtered atoms then travel through the chamber and condense on a substrate, forming a thin film. The sputtering yield quantifies the efficiency of this initial ejection step.

The Key Factors Controlling Sputter Yield

The yield is a function of a predictable set of variables. By tuning these parameters, you can directly control the outcome of your deposition process.

Ion Energy and Mass

The energy of the bombarding ions is a primary control knob. As ion energy increases, more momentum is transferred during the collision, resulting in a higher sputtering yield. This effect is most prominent in the typical energy range of 10 to 5000 eV.

Similarly, the mass of the sputtering gas ion matters. A heavier ion (like Krypton or Xenon) will transfer more momentum than a lighter one (like Argon), leading to a higher yield under the same conditions.

Target Material Properties

The target material itself has the largest influence on yield. Two properties are critical:

- Surface Binding Energy: Materials with weaker atomic bonds have a lower surface binding energy, making them easier to sputter.

- Atomic Mass: The most efficient energy transfer occurs when the mass of the incident ion and the target atom are similar.

For example, Silver (Ag) has a relatively high sputtering yield because its atomic mass is a reasonable match for Argon and it has moderate binding energy. In contrast, Iron (Fe) has a much lower yield due to its stronger atomic bonds.

Angle of Ion Incidence

Sputtering yield is also dependent on the angle at which ions strike the target. A perpendicular, 90° impact is often less efficient than an oblique angle.

Yield typically increases as the angle moves away from normal incidence, peaks, and then falls off at very shallow angles. This is because a glancing blow is more effective at ejecting surface atoms without burying energy deep inside the target. This phenomenon contributes to the formation of a "race track" groove on used targets, where sputtering has been most intense.

Understanding the Trade-offs

Maximizing sputter yield is not always the primary goal. Achieving a high deposition rate often comes with compromises that can affect cost and film quality.

High Yield vs. Film Quality

Simply increasing ion energy to get a higher yield can be detrimental. Excessively high-energy bombardment can cause damage to the growing film, implant sputtering gas into the film, and increase compressive stress, altering the desired material properties.

Deposition Rate vs. Cost

While a high yield provides a fast deposition rate, the choice of sputtering gas involves a trade-off. Heavier gases like Krypton increase yield but are significantly more expensive than Argon, which is the industry standard for its balance of performance and cost.

Target Utilization and the "Race Track"

The non-uniform erosion profile known as a "race track" is a direct consequence of sputter yield being highest in specific areas. This leads to poor target utilization, as significant amounts of expensive target material are left unused when the groove becomes too deep. Advanced magnetron designs aim to mitigate this for better cost-efficiency.

Optimizing Sputter Yield for Your Goal

Your ideal sputter yield depends entirely on your objective. Use these principles to guide your process decisions.

- If your primary focus is maximum deposition rate: Increase ion energy and consider using a heavier sputtering gas, but monitor the film for unwanted stress or gas incorporation.

- If your primary focus is film quality and density: Use moderate ion energies to ensure good film adhesion and structure without introducing damage from excessive bombardment.

- If your primary focus is cost-efficiency and material utilization: Optimize your system's geometry and magnetic fields (in magnetron sputtering) to promote uniform target erosion, even if it means sacrificing the absolute maximum yield.

By mastering these variables, you gain precise control over the efficiency and outcome of your thin-film deposition process.

Summary Table:

| Factor | Effect on Sputtering Yield |

|---|---|

| Ion Energy | Increases with higher energy (10-5000 eV range) |

| Ion Mass | Heavier ions (e.g., Xe, Kr) yield more than lighter ions (e.g., Ar) |

| Target Material | Higher yield for materials with lower surface binding energy and mass similar to the ion |

| Angle of Incidence | Increases at oblique angles (peaks before falling off at shallow angles) |

Ready to optimize your sputtering process for maximum deposition rate, superior film quality, or cost-efficiency?

The principles of sputtering yield are key to engineering your thin-film outcomes. At KINTEK, we specialize in providing the high-quality lab equipment and expert support you need to master your deposition process.

Whether you are researching new materials or scaling up production, our range of sputtering targets and systems can help you achieve precise control and reliable results.

Contact our experts today to discuss how we can support your laboratory's specific thin-film deposition needs.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Cold Trap Direct Cold Trap Chiller

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What is the speed of PECVD? Achieve High-Speed, Low-Temperature Deposition for Your Lab

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process