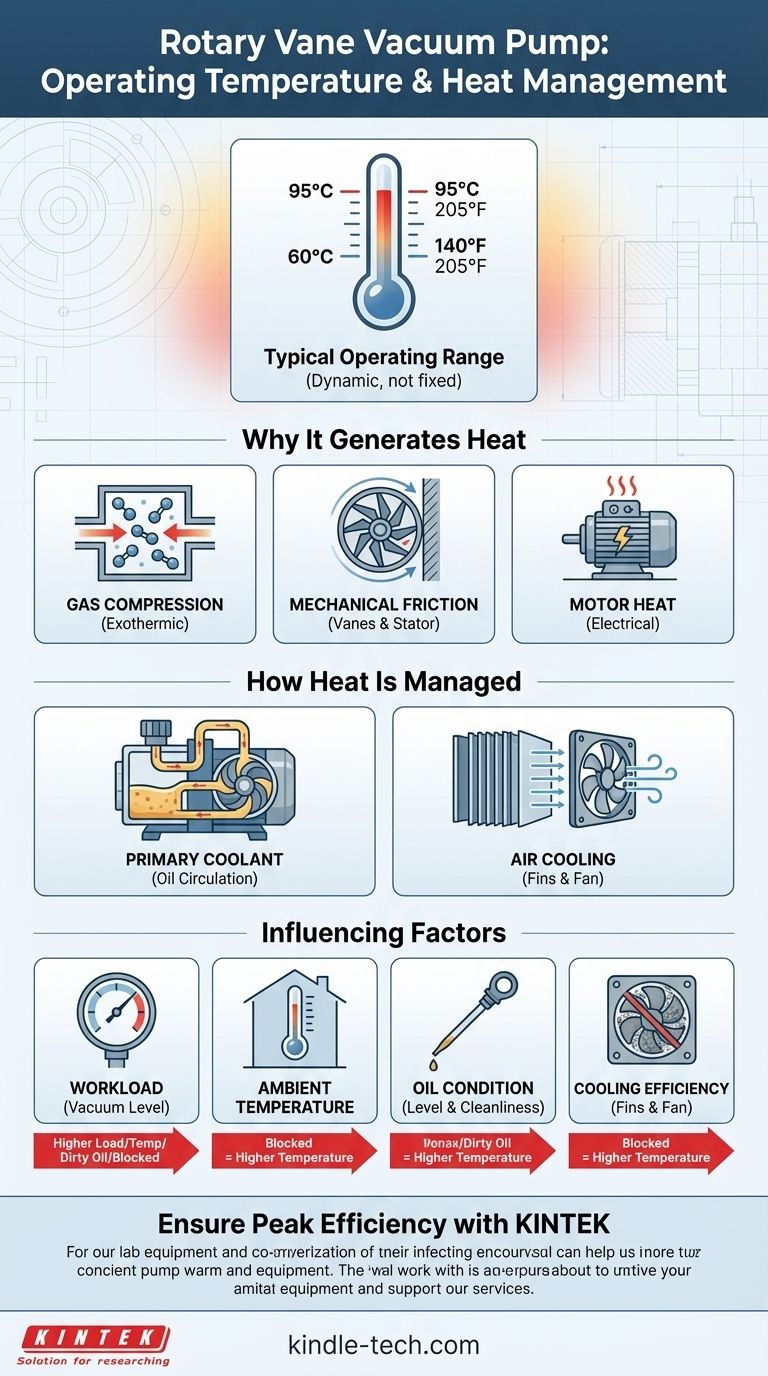

The typical operating temperature of an oil-sealed rotary vane vacuum pump is generally between 60°C and 95°C (140°F to 205°F). However, there is no single universal temperature, as it depends heavily on the specific pump model, the workload (vacuum level), and the ambient environment. The heat is a natural byproduct of the pump's mechanical operation and the physics of gas compression.

A rotary vane pump's temperature is not a fixed value but a dynamic indicator of its workload and health. Understanding the sources of this heat—primarily gas compression and mechanical friction—is more critical than targeting a single temperature number.

Why Rotary Vane Pumps Generate Heat

A pump's operating temperature is a direct result of its core function. The energy used to move gas molecules from a low-pressure environment to a high-pressure one is converted into heat.

The Physics of Gas Compression

As the pump draws in gas molecules and its internal chambers shrink, it compresses the gas before expelling it to the atmosphere. This act of compression is an exothermic process, meaning it releases energy in the form of heat. The harder the pump works, the more heat it generates.

Mechanical Friction

The pump's design involves vanes sliding against the internal wall of the pump housing (the stator). As the rotor spins at high speed, centrifugal force pushes these vanes outward, creating friction. While the specially formulated oil provides lubrication, this constant mechanical contact is a significant and continuous source of heat.

The Role of the Motor

The electric motor that drives the pump is another source of heat. Whether it is a direct-drive or belt-drive model, the motor naturally heats up during operation, and this thermal energy is transferred to the pump body.

How Pumps Manage This Heat

Efficiently managing heat is critical for a pump's performance and longevity. The design incorporates several mechanisms to dissipate the thermal energy it creates.

Oil as a Primary Coolant

The oil in a rotary vane pump serves three crucial functions: sealing, lubrication, and cooling. As oil circulates, it absorbs heat directly from the hot metal components like the rotor, vanes, and stator. This heat is then carried to the pump's outer casing where it can be released.

Air Cooling and Fins

Most pumps feature cooling fins on their exterior housing, which increase the surface area available for heat dissipation. A fan, typically mounted on the motor shaft, blows ambient air over these fins to carry the heat away, much like the radiator in a car.

Factors Influencing Operating Temperature

The final, stable temperature of your pump is a balance between heat generation and heat dissipation. Several factors can shift this balance.

Vacuum Level (Workload)

A pump pulling a very deep vacuum or moving a high volume of gas is working harder and will generate more heat from compression. A pump running at a lighter load will naturally run cooler.

Ambient Temperature

The temperature of the surrounding air directly impacts the pump's ability to cool itself. A pump operating in a hot, poorly ventilated room will run at a significantly higher temperature than one in a cool, well-ventilated space.

Oil Condition and Level

Using the wrong type of oil, or allowing the oil level to drop too low, severely compromises its ability to lubricate and cool the pump. Old, contaminated oil also loses its thermal efficiency, causing the pump to run hotter.

Making the Right Choice for Your Goal

Instead of focusing on a single number, treat the pump's temperature as a vital sign of its health. Establishing a baseline for your specific setup is key.

- If your primary focus is routine operation: Let the pump run under its normal load and note its stable temperature. Use this as your benchmark to quickly identify future problems.

- If your primary focus is maintenance and longevity: Regularly check that the oil level is correct, the oil is clean, and the pump's cooling fins and fan are free of dust and debris to ensure optimal heat dissipation.

- If your primary focus is troubleshooting a hot pump: Immediately check the oil level, verify adequate ventilation around the unit, and ensure the workload is within the pump's specified limits.

Monitoring your pump's temperature is the most effective way to ensure its long-term reliability and performance.

Summary Table:

| Factor | Impact on Temperature |

|---|---|

| Vacuum Level / Workload | Higher load = higher temperature |

| Ambient Temperature | Hotter environment = higher temperature |

| Oil Condition & Level | Low/dirty oil = higher temperature |

| Cooling System Efficiency | Blocked fins/fan = higher temperature |

Ensure your lab's vacuum pumps run at peak efficiency. KINTEK specializes in lab equipment and consumables, providing reliable rotary vane vacuum pumps and expert maintenance support to protect your experiments and extend equipment life. Contact our experts today for a consultation on the right pump for your needs!

Visual Guide

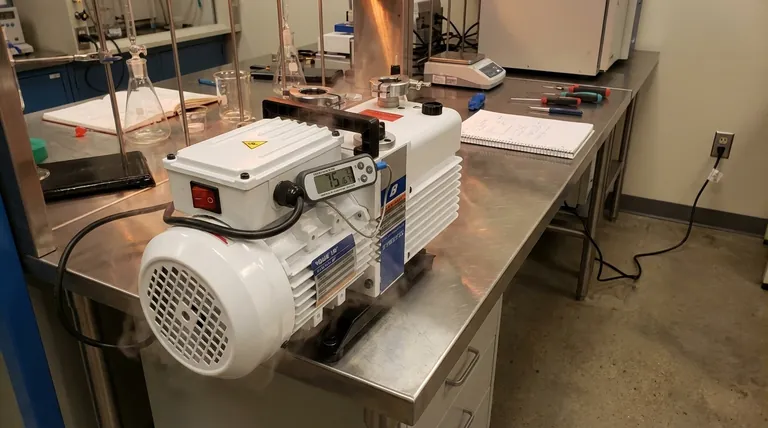

Related Products

- Laboratory Rotary Vane Vacuum Pump for Lab Use

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- Why are PID temperature controllers and internal cooling systems essential for autohydrolysis? Precision & Quenching

- Why are polyethylene ball milling jars preferred over stainless steel for battery electrode materials?

- What is the compressive strength of fused quartz? >1.1 GPa, But It's the Other Properties That Matter

- What purpose do steel grinding balls serve in NiAl-Al2O3 mechanical alloying? Optimize Your Material Synthesis

- Why must a KEMS chamber have a turbomolecular pump? Ensure Ultra-High Vacuum for Precise Mass Spectrometry

- Why are tungsten carbide grinding jars and balls preferred for high-purity lithium ceramic powders? Ensure Peak Purity.

- What problem does a multi-stage condenser system solve in vacuum carbothermic magnesium production? Safety & Purity

- What is the purpose of using a stirring device with an ice bath? Master Cellulose/Ag2S Composite Synthesis