In short, argon is the standard gas for sputtering because it is chemically inert and possesses an ideal atomic mass. This unique combination ensures that it efficiently dislodges atoms from the target material without reacting with them, resulting in a pure, high-quality deposited film.

The core principle is this: Sputtering is a purely physical, not chemical, process. The choice of argon is a strategic decision to enable an efficient "molecular sandblasting" effect while preventing any unwanted chemical reactions that would contaminate the final thin film.

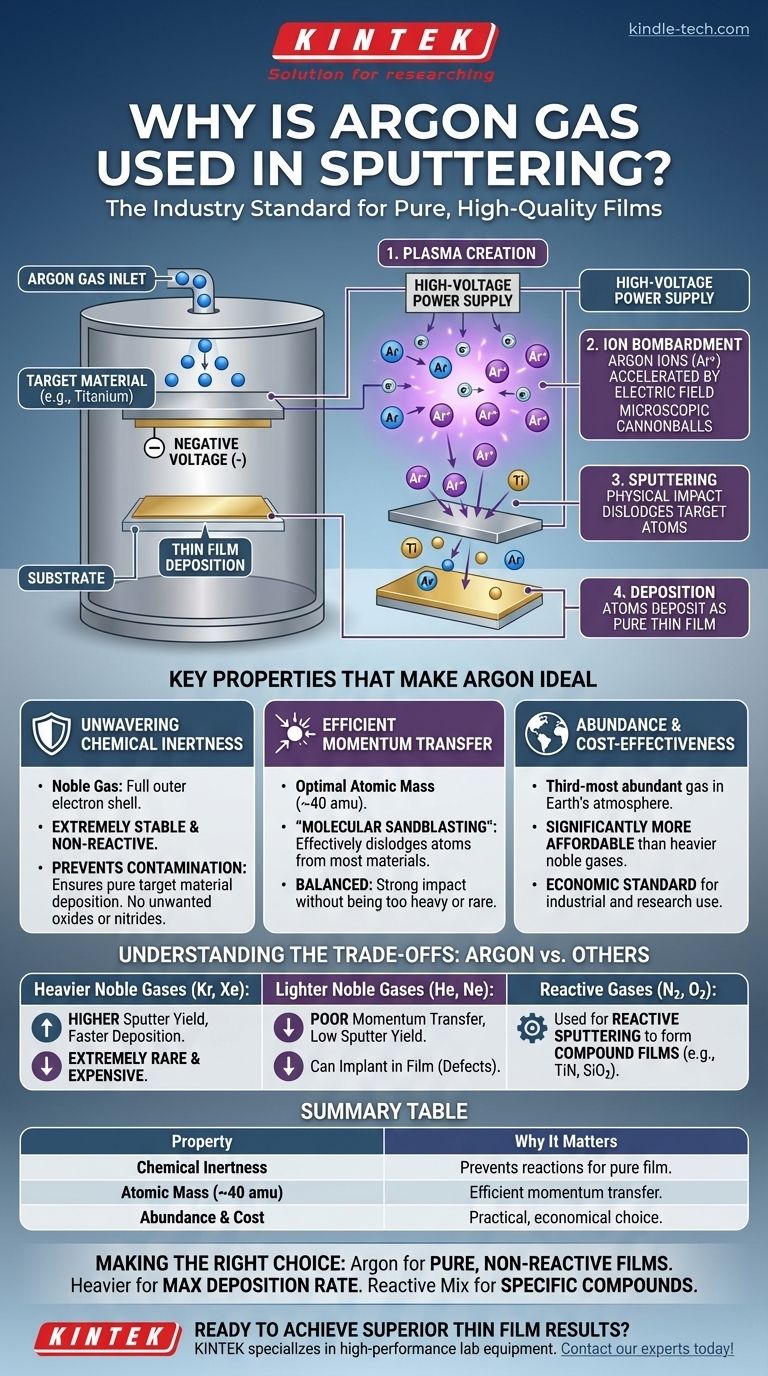

The Fundamental Role of Gas in Sputtering

Creating the Plasma

Sputtering begins by introducing a low-pressure gas, typically argon, into a vacuum chamber. A high voltage is then applied to the target material you wish to deposit.

This strong electric field strips electrons from the argon atoms, creating a mixture of positively charged argon ions and free electrons. This energized, ionized gas is known as plasma.

The Bombardment Process

The positively charged argon ions are accelerated by the electric field and slam into the negatively charged target material.

Think of these ions as microscopic cannonballs. Each impact has enough kinetic energy to physically knock atoms loose from the target's surface, "sputtering" them into the vacuum chamber where they travel and deposit onto a substrate as a thin film.

Key Properties That Make Argon Ideal

1. Unwavering Chemical Inertness

Argon is a noble gas, meaning its outermost electron shell is full. This makes it extremely stable and non-reactive.

This inertness is critical. The goal of sputtering is to deposit a film of the pure target material (e.g., pure titanium). If a reactive gas like oxygen or nitrogen were used, it would form oxides or nitrides on the target and in the film, altering its fundamental properties.

2. Efficient Momentum Transfer

Sputtering efficiency, or sputter yield, depends on how effectively the bombarding ion can transfer its momentum to the target atoms.

Argon's atomic mass (39.9 amu) is heavy enough to effectively dislodge atoms from most common target materials. It strikes a perfect balance, providing a strong physical impact without being excessively rare or difficult to handle.

3. Abundance and Cost-Effectiveness

While other noble gases could be used, argon is the third-most abundant gas in Earth's atmosphere.

This natural abundance makes argon significantly more affordable than heavier, more-efficient noble gases like Krypton or Xenon, establishing it as the economic standard for industrial and research applications.

Understanding the Trade-offs: Argon vs. Other Gases

Heavier Noble Gases (Krypton, Xenon)

Krypton and Xenon are significantly heavier than argon. This allows them to transfer more momentum upon impact, leading to a higher sputter yield and faster deposition rates.

However, their extreme rarity makes them prohibitively expensive for all but the most specialized, high-value applications where maximum deposition rate is the absolute priority.

Lighter Noble Gases (Helium, Neon)

Helium and Neon are much lighter than argon, resulting in poor momentum transfer and a very low sputter yield.

Furthermore, these smaller ions have a higher tendency to become embedded or "implanted" in the growing film, which can cause undesirable material stress and defects.

Reactive Gases (Nitrogen, Oxygen)

Sometimes, the goal is to create a compound film. In a process called reactive sputtering, a gas like nitrogen or oxygen is intentionally added to the argon plasma.

In this case, the argon still performs the primary sputtering, while the reactive gas combines with the sputtered target atoms to form a new compound on the substrate, such as titanium nitride (TiN) or silicon dioxide (SiO2).

Making the Right Choice for Your Sputtering Goal

The ideal process gas is always dictated by the desired properties of your final film.

- If your primary focus is pure, non-reactive film deposition: Argon is the industry standard, offering the best balance of sputtering efficiency, chemical inertness, and cost.

- If your primary focus is maximizing deposition rate at any cost: Heavier noble gases like Krypton or Xenon may be justified for their superior sputter yield in highly specialized applications.

- If your primary focus is creating a specific compound film: A carefully controlled mixture of argon and a reactive gas (like oxygen or nitrogen) is necessary to achieve the desired chemical composition.

Ultimately, understanding argon's role is key to mastering the control and precision of the sputtering process.

Summary Table:

| Property | Why It Matters for Sputtering |

|---|---|

| Chemical Inertness | Prevents unwanted reactions, ensuring a pure film of the target material. |

| Atomic Mass (~40 amu) | Enables efficient momentum transfer for high sputter yield. |

| Abundance & Cost | Makes it the most practical and economical choice for most applications. |

Ready to achieve superior thin film results with your sputtering process? The right equipment is key to leveraging argon's full potential. At KINTEK, we specialize in high-performance lab equipment, including sputtering systems designed for precision and reliability. Whether you're depositing pure metals or complex compounds, our solutions help you maximize efficiency and film quality. Contact our experts today to discuss how we can support your laboratory's specific needs!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- What are the hazards of infrared spectroscopy? Understanding Sample Prep and Instrument Safety

- What are the limitations of fluidized bed reactor? Key Challenges in Design and Operation

- What controls melting point? The Hierarchy of Forces from Ionic Bonds to Intermolecular Attractions

- What is the temperature involved in the brazing process? Master the 4 Critical Phases for Perfect Joints

- What are the components of a rotavap? Master Gentle Evaporation for Sensitive Compounds

- What is the strength of the magnetron magnetic field? It's About Function, Not Just Force

- What should be considered when performing melting point determination? Ensure Accurate Compound Identification and Purity Assessment

- What is a natural sintering? Uncover the Geological Process That Forms Ore Deposits