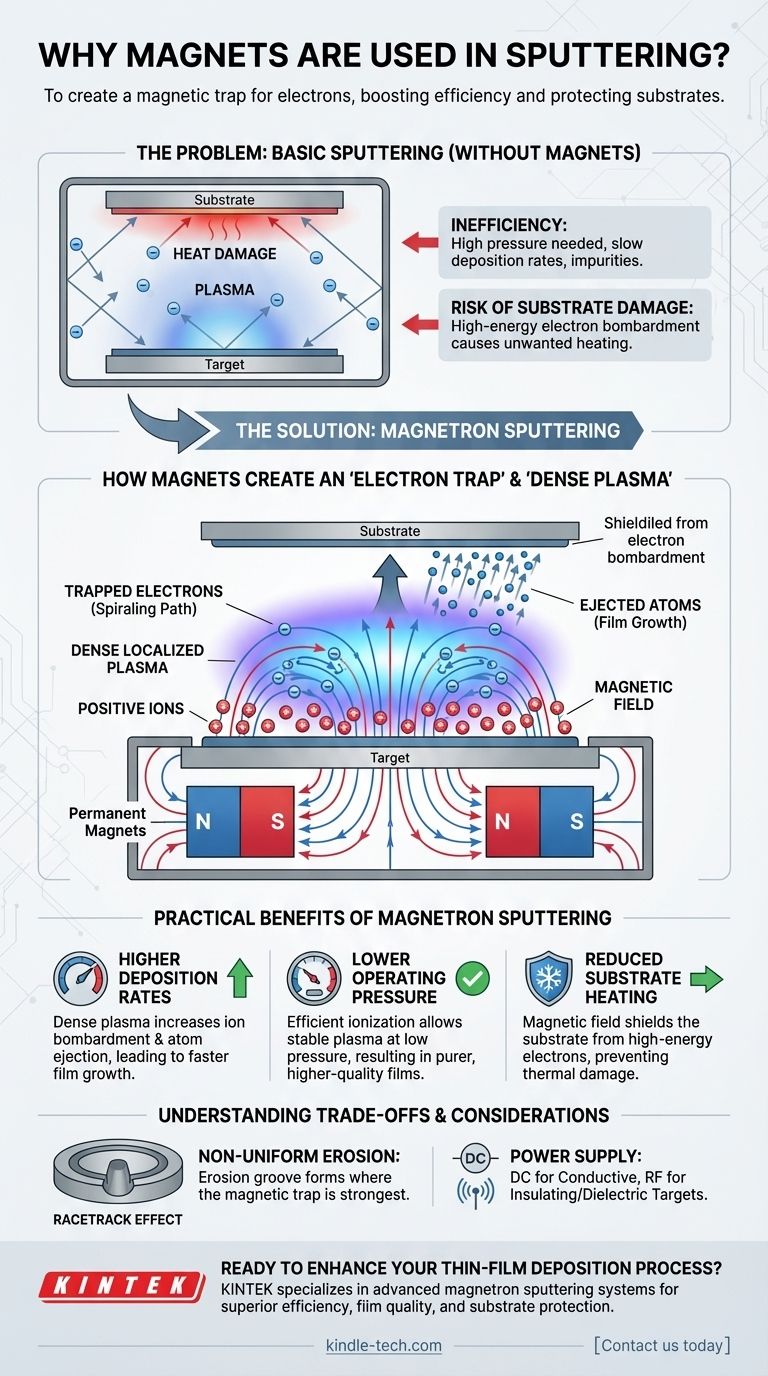

In short, magnets are used in sputtering to create a magnetic trap for electrons. This trap confines the plasma directly over the target material, forcing electrons into a longer, spiraling path. These trapped electrons collide much more frequently with neutral gas atoms, dramatically increasing the rate of ionization and creating a dense cloud of positive ions that bombard the target, resulting in a significantly more efficient sputtering process.

The core function of magnets is to transform standard sputtering into a highly efficient process. By trapping electrons, they create a dense, localized plasma that boosts deposition rates at lower pressures and protects the substrate from damaging high-energy electron bombardment.

The Fundamental Problem Magnets Solve

To understand why magnets are so crucial, it's important to first recognize the limitations of a basic sputtering system that lacks them.

The Inefficiency of Basic Sputtering

In a simple sputtering setup, free electrons generated in the plasma can easily escape and travel to the chamber walls or the substrate.

This rapid loss of electrons means you need a relatively high gas pressure to ensure enough collisions occur to sustain the plasma, which is inefficient and can lead to impurities in the deposited film.

The Risk of Substrate Damage

High-energy electrons that escape the plasma can bombard the substrate where your film is growing.

This bombardment can cause significant and unwanted heating, potentially damaging sensitive substrates like plastics or delicate electronic components.

How Magnets Create an "Electron Trap"

Adding strong permanent magnets or electromagnets behind the sputtering target—a configuration known as a magnetron—fundamentally changes the physics of the process.

The Role of Magnetic Fields

The magnets are arranged to create a magnetic field with lines of flux running parallel to the face of the target.

This magnetic field intersects with the electric field that is accelerating the ions, creating a powerful confinement zone.

Confining Electron Movement

Electrons are lightweight charged particles and are therefore heavily influenced by the magnetic field. Instead of moving in a straight line, they are forced into a tight, spiral path along the magnetic field lines.

This effectively traps the electrons, preventing them from escaping the region directly above the target.

Creating a Dense, Localized Plasma

Because the electrons are trapped, their path length within the plasma is extended by orders of magnitude. This drastically increases the probability that they will collide with and ionize neutral gas atoms (typically Argon).

The result is a dense, intense, and self-sustaining plasma concentrated right where it's needed—directly over the target material.

The Practical Benefits of Magnetron Sputtering

This magnetically-enhanced plasma provides several critical advantages that have made magnetron sputtering an industry standard.

Higher Deposition Rates

A denser plasma means a much higher concentration of positive ions is available to bombard the target. More ions hitting the target per second means more atoms are ejected, leading to significantly faster film growth and higher manufacturing throughput.

Lower Operating Pressure

Because the electron trap is so effective at causing ionization, a stable plasma can be sustained at much lower gas pressures.

Operating at lower pressure is highly desirable because it leads to a cleaner deposition environment, resulting in a purer film with better density and fewer defects from incorporated gas atoms.

Reduced Substrate Heating

The magnetic field effectively acts as a shield, keeping the vast majority of high-energy electrons confined near the target and away from the substrate.

This prevention of electron bombardment is critical for depositing high-quality films onto temperature-sensitive materials without causing thermal damage.

Understanding the Trade-offs

While immensely powerful, the magnetron configuration is not without its own specific characteristics and limitations.

The "Racetrack" Effect

The ion bombardment is not uniform across the entire target surface. It is most intense where the magnetic trap is strongest, leading to a visible erosion groove often called a "racetrack."

This means that target material utilization is not 100%, as the center and outer edges of the target erode much more slowly.

Power Supply Considerations

For electrically conductive targets, a simple Direct Current (DC) power supply is sufficient.

However, for insulating or dielectric target materials, a charge can build up on the surface and "poison" the process. This requires the use of a more complex Radio Frequency (RF) power supply to alternately neutralize the charge buildup.

Making the Right Choice for Your Goal

The use of magnets is a defining feature of modern, high-performance sputtering systems. Understanding their impact helps in optimizing any deposition process.

- If your primary focus is speed and throughput: Magnetron sputtering is non-negotiable, as the electron trap directly translates to the highest possible deposition rates.

- If your primary focus is film purity and quality: The ability to operate at lower pressures is a key advantage of magnetrons, reducing gas incorporation and leading to a denser, higher-quality film.

- If your primary focus is depositing on sensitive substrates: The magnetic confinement of electrons is the best method for preventing heat damage, making it the superior choice for plastics, polymers, or delicate electronics.

Ultimately, adding magnets transforms sputtering from a basic physical phenomenon into a precise, efficient, and highly controllable manufacturing process.

Summary Table:

| Benefit | How Magnets Help |

|---|---|

| Higher Deposition Rates | Trapped electrons create a dense plasma, increasing ion bombardment and atom ejection from the target. |

| Lower Operating Pressure | Efficient ionization allows a stable plasma at lower pressures, resulting in purer, higher-quality films. |

| Reduced Substrate Heating | Magnetic fields confine high-energy electrons away from the substrate, preventing thermal damage. |

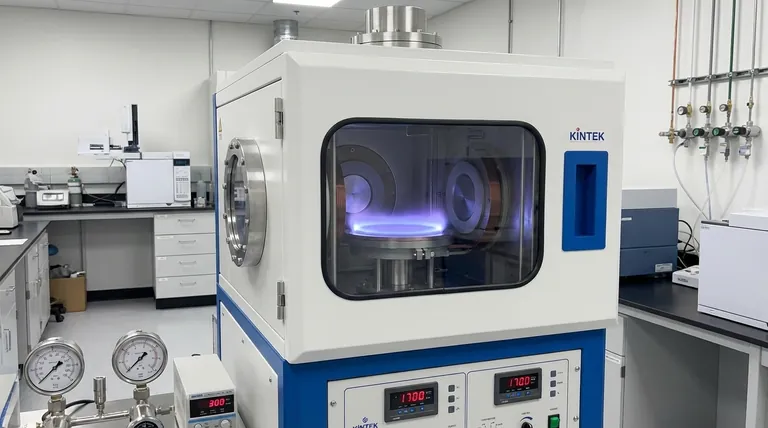

Ready to enhance your thin-film deposition process? KINTEK specializes in advanced lab equipment, including magnetron sputtering systems designed for superior efficiency, film quality, and substrate protection. Our solutions are tailored to meet the precise needs of your laboratory. Contact us today to discuss how our expertise can benefit your research or production goals!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Polygon Press Mold for Lab

- Platinum Auxiliary Electrode for Laboratory Use

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What is the temperature of PECVD deposition? Achieve High-Quality Films at Low Temperatures

- What are the uses of PECVD? A Guide to Low-Temperature Thin-Film Deposition

- What is the difference between PECVD and sputter? Choose the Right Thin-Film Deposition Method