Introduction to Handheld Alloy Analyzers

Handheld alloy analyzers have revolutionized the field of material analysis by bringing advanced technology to the fingertips of professionals. These compact devices utilize cutting-edge techniques such as X-ray fluorescence (XRF) and laser-induced breakdown spectroscopy (LIBS) to provide fast, accurate, and non-destructive testing. From their origins in traditional lab-based analysis, handheld alloy analyzers have evolved into portable solutions that offer unprecedented convenience and efficiency. This guide delves into the features, applications, and benefits of these innovative tools, highlighting how they transform quality control and material analysis across various industries.

Key Features of Handheld Alloy Analyzers

Handheld alloy analyzers have become indispensable tools in various industries due to their advanced features that facilitate rapid, accurate, and non-destructive analysis of alloy compositions. These devices are equipped with cutting-edge technologies that not only enhance their functionality but also make them user-friendly and adaptable to a wide range of applications.

Fast Analysis Times

One of the most significant advantages of handheld alloy analyzers is their ability to deliver results quickly. For instance, the Alloy-Handheld X-ray Fluorescence (XRF) Analyzer can identify alloy grades within 1-2 seconds using advanced algorithms like the fundamental parameters method (FP). This rapid analysis capability is crucial in industries where time is of the essence, such as metal recycling and quality control in manufacturing. The fast detection speed, often achieved under specific conditions like 8.5μA current and 38kV voltage, ensures that users can perform multiple tests in a short span, significantly boosting productivity.

Non-Destructive Testing Capabilities

Handheld alloy analyzers operate on non-destructive testing principles, preserving the integrity of the samples being analyzed. This is particularly beneficial in scenarios where the original samples need to be retained for further analysis or other purposes. The non-destructive nature of the tests allows for comprehensive and repeated testing without altering the sample, which is a critical feature in forensic applications and historical artifact analysis.

Wide Elemental Analysis Range

These analyzers are designed to detect a broad spectrum of elements, from light elements like magnesium and aluminum to heavy metals such as lead and tungsten. This wide detection range makes them versatile tools for analyzing various types of alloys, including those used in aerospace, automotive, and construction industries. The ability to simultaneously detect multiple elements in a single measurement provides a comprehensive view of the alloy's composition, aiding in precise alloy identification and quality assurance.

User-Friendly Interfaces

Modern handheld alloy analyzers are equipped with user-friendly interfaces that simplify operation and data interpretation. Features such as a 5-inch high-definition industrial-grade screen and intuitive touch controls make these devices accessible even to users with minimal technical training. The ergonomic design, lightweight construction, and good balance ensure comfort during extended use, while long-lasting batteries support uninterrupted fieldwork.

Safety and Reliability

Safety is a paramount concern in any analytical equipment, and handheld alloy analyzers are designed with multiple safety features. These include material sensing functions, intelligent status display lights, and safety linkage devices that enhance the instrument's reliability and safety during operation. Additionally, the rugged design and protective covers with calibration, anti-radiation, and anti-damage functions ensure the safety of both the operator and the instrument.

Cost-Effectiveness

Beyond their technical capabilities, handheld alloy analyzers offer significant cost savings. They reduce the need for laboratory-based analyses and sample transportation, thereby lowering the overall cost of material testing. Quick analysis results also enable timely adjustments in industrial processes, preventing resource wastage and enhancing operational efficiency.

In conclusion, handheld alloy analyzers are revolutionary tools that combine speed, accuracy, and ease of use with a strong emphasis on safety and cost-effectiveness. Their ability to perform non-destructive, wide-ranging elemental analyses makes them invaluable in a multitude of industries, from metallurgy and manufacturing to environmental monitoring and cultural heritage preservation. As technology continues to advance, these devices will undoubtedly play an even more significant role in shaping the future of material analysis and quality control.

Technical Specifications and Performance Metrics

Handheld alloy analyzers are critical tools in various industries, offering rapid and accurate elemental analysis for quality assurance and control. These devices are designed to operate under diverse conditions, ensuring high performance and reliability. This section delves into the technical specifications and performance metrics that define the capabilities of handheld alloy analyzers, including detection limits, accuracy, resolution, and the impact of factors like voltage and current on test results.

Detection Limits and Accuracy

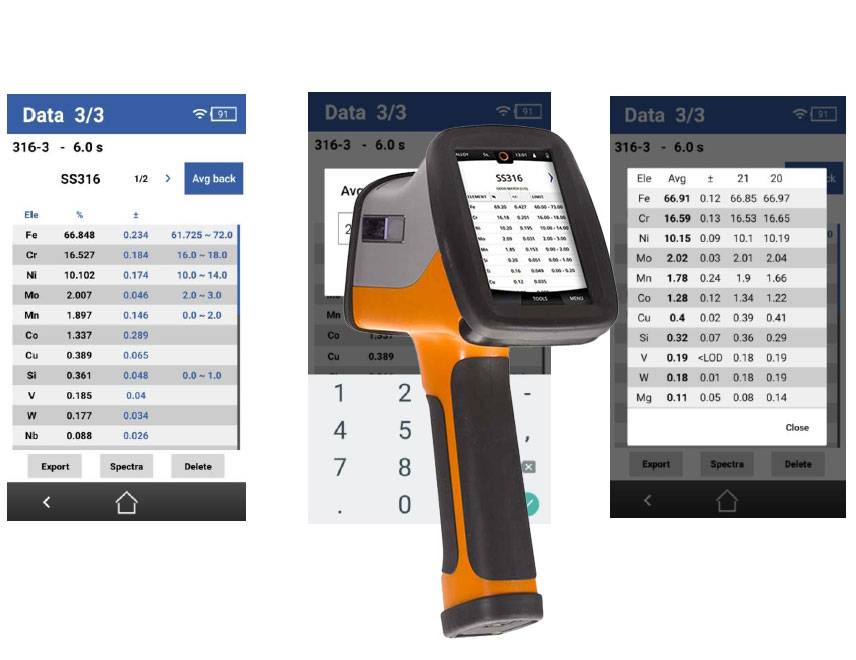

Handheld alloy analyzers, such as the XRF900 Series, are equipped with advanced algorithms like the fundamental parameters method (FP), enabling them to identify alloy grades within 1-2 seconds. These analyzers boast high detection accuracy, with the ability to average multiple test results to enhance precision. For instance, under conditions of 8.5μA current and 38kV voltage, these devices can measure elements in alloys like 316, clearly identifying peaks for elements such as Cr, Mn, Fe, Co, Ni, and Mo. This level of accuracy is crucial for industries requiring precise alloy composition analysis, such as aerospace and automotive.

Resolution and Operational Specifications

The resolution of handheld alloy analyzers is a key factor in their performance. These devices operate at low detector temperatures, sometimes as low as -35°C, which enhances their resolution capabilities. The high-definition resolution display screens provided with these analyzers allow users to view and edit test information and results on-site, facilitating immediate analysis and decision-making.

Impact of Voltage and Current

The operational voltage and current significantly influence the performance of handheld alloy analyzers. For example, a higher voltage can improve the penetration depth of X-rays, allowing for analysis of thicker or denser materials. Conversely, a lower current reduces the radiation dose, making the device safer for operators. The optimal settings depend on the specific application and the type of material being analyzed.

Applications and Industry Specifics

Handheld alloy analyzers are versatile tools with applications across various industries. In aerospace, these devices verify high-temperature nickel alloys, titanium alloys, and superalloys, ensuring components can withstand extreme conditions. They also analyze lightweight elements in aluminum and titanium alloys, crucial for reducing weight in aircraft and spacecraft. In the recycling industry, these analyzers help sort and identify different types of metals, improving efficiency and accuracy in recycling processes.

Maintenance and User-Friendliness

These analyzers are designed for minimal maintenance, with features like anti-puncture windows protecting the front end of the device. The ergonomic design, lightweight, and small size make them easy to handle, even during extended periods of use. Battery life is substantial, ensuring uninterrupted operation during on-site testing without the need for frequent recharging.

Conclusion

Handheld alloy analyzers are indispensable in modern industries, offering rapid, accurate, and non-destructive analysis of metal alloys. Their technical specifications, including detection limits, accuracy, and resolution, are tailored to meet the stringent requirements of various applications. By understanding and optimizing these metrics, industries can ensure the reliability and safety of their products, from production to assembly.

Applications in Various Industries

Handheld alloy analyzers have revolutionized the way industries manage quality control and material analysis. These portable devices offer rapid, non-destructive testing capabilities that are essential in sectors where precision and reliability are paramount. This section delves into the diverse applications of handheld alloy analyzers across industries such as aerospace, automotive, metallurgy, and jewelry, highlighting case studies where these devices have significantly improved quality control and material analysis.

Aerospace Industry

In the aerospace sector, the demand for high-performance materials that can withstand extreme conditions is critical. Handheld alloy analyzers, such as X-ray fluorescence (XRF) and laser-induced breakdown spectroscopy (LIBS) devices, are instrumental in verifying the composition of critical alloys used in aircraft components. These analyzers can:

- Verify high-temperature nickel alloys, titanium alloys, aluminum alloys, and super alloys: Ensuring that these materials meet the stringent specifications required for aerospace applications.

- Analyze lightweight elements in aluminum and titanium alloys: These elements are crucial for reducing weight while maintaining structural integrity.

- Detect high-purity tin and prevent tin whisker formation: Tin whiskers can cause short circuits and failures in electronic systems, making early detection essential.

- Measure the thickness of cadmium and zinc-nickel coatings: These coatings protect against corrosion and are vital for the longevity of aerospace components.

Automotive Industry

The automotive industry benefits significantly from handheld alloy analyzers in ensuring the quality and safety of vehicles. These devices are used for:

- Material verification in car bodies and engine components: Analyzing the composition of steel, aluminum, and other alloys to ensure they meet performance standards.

- Recycling and sorting of scrap metals: Accurate identification of metal types helps in efficient recycling processes, reducing waste and environmental impact.

- Quality control in manufacturing: Real-time analysis helps in identifying defects and ensuring that each component meets the required specifications.

Metallurgy Industry

In metallurgy, handheld alloy analyzers play a crucial role in the production and quality assurance of metals. They are used for:

- Real-time analysis during metal production: Monitoring the composition of alloys as they are being produced, ensuring consistency and quality.

- Identification of impurities and contaminants: Early detection of impurities helps in maintaining the purity of metals, which is essential for high-performance applications.

- Research and development: Analyzing new alloy formulations to optimize properties for specific applications.

Jewelry Industry

The jewelry industry relies on handheld alloy analyzers to authenticate the purity and composition of precious metals. These devices are invaluable for:

- Testing gold, silver, and platinum: Ensuring that jewelry items meet the required purity standards and are free from adulterants.

- Identifying counterfeit metals: Protecting consumers from purchasing fake or substandard products.

- Quality control in jewelry manufacturing: Ensuring that each piece of jewelry meets the specified metal content and quality.

Advantages of Handheld Alloy Analyzers

Handheld alloy analyzers have revolutionized the way materials are analyzed, offering numerous advantages that were previously unattainable with traditional laboratory-based methods. These devices, often based on technologies such as X-ray fluorescence (XRF) or laser-induced breakdown spectroscopy (LIBS), provide fast, accurate, and non-destructive analysis of alloy compositions directly in the field. This section delves into the tangible benefits of using handheld alloy analyzers, including cost savings, time efficiency, safety enhancements, and the ability to perform real-time analysis in various conditions.

Cost Savings

One of the most significant advantages of handheld alloy analyzers is the substantial cost savings they offer. Traditional methods of materials analysis required sending samples to a laboratory, which involved not only the cost of transportation but also the expense of using large, specialized equipment. Handheld analyzers eliminate these costs by allowing on-site analysis. For instance, the XRF 900S Series handheld alloy analyzer requires no sample preparation and provides reliable quantitative analysis results in a short detection time. This not only reduces the need for laboratory visits but also minimizes the labor and material costs associated with sample preparation and handling.

Time Efficiency

Time efficiency is another critical benefit of handheld alloy analyzers. With traditional methods, the turnaround time for analysis could be lengthy, often delaying project progress. Handheld devices, such as the XRF 900S series, enable engineers, technicians, and field operators to carry out fast and accurate analysis of materials on the spot. These devices can determine the composition of an alloy in seconds, providing detailed analysis results, including elemental percentages, amounts, and possible impurities. This rapid analysis capability significantly speeds up decision-making processes, allowing for more timely adjustments and optimizations in various industrial applications.

Safety Enhancements

Safety is a paramount concern in many industrial settings, and handheld alloy analyzers contribute significantly to enhancing safety measures. These devices are designed for non-destructive testing, meaning they do not alter or damage the samples being analyzed. This is particularly important in industries where preserving the integrity of materials is crucial. Additionally, the portability and ease of use of these analyzers reduce the need for manual handling of samples, thereby minimizing the risk of injuries or accidents. The XRF 900S series, for example, is equipped with a high-performance X-ray tube and Si-Pin/SDD detector, ensuring safe and accurate analysis without the need for hazardous chemicals or complex procedures.

Real-Time Analysis in Field Conditions

The ability to perform real-time analysis in field conditions is a game-changer for many industries. Handheld alloy analyzers, such as the handheld spectrum analyzer mentioned earlier, can operate in low-temperature conditions (-35°C) and provide high-resolution analysis. These devices can access difficult-to-reach locations, such as the inner walls of pipelines or weld seams, and provide immediate feedback on the composition of materials. This real-time analysis capability is invaluable in scenarios where immediate decisions need to be made, such as in emergency repairs, quality control checks, or during exploratory missions in remote areas.

Comprehensive Elemental Analysis

Handheld alloy analyzers offer comprehensive elemental analysis, capable of detecting multiple elements simultaneously. This includes a wide range from light elements to heavy metals, providing a detailed elemental composition of the alloy in a single measurement. For example, handheld ore analyzers can detect multiple elements at once, offering comprehensive data support for prospecting. This non-destructive testing method preserves the original samples, allowing for subsequent laboratory analysis or other purposes, such as further mineralogical research or environmental impact assessment.

Strong Adaptability and Cost-Effectiveness

Handheld alloy analyzers are designed to be compact, lightweight, and adaptable to various field environments. This includes remote areas and extreme climatic conditions, making them suitable for use in places that are difficult to access for traditional laboratory analysis. By reducing the time and cost of sample transportation and laboratory analysis, these devices improve the cost-effectiveness of the entire process. Quick analysis results also enable timely adjustments to exploration plans, avoiding wasting resources in low-value areas.

In conclusion, handheld alloy analyzers offer a multitude of advantages that make them indispensable tools in various industries. From cost savings and time efficiency to safety enhancements and real-time analysis capabilities, these devices have revolutionized materials analysis, providing comprehensive, accurate, and timely data to support decision-making processes. As technology continues to advance, the benefits of handheld alloy analyzers are only expected to grow, further solidifying their role as essential instruments in modern industrial applications.

Comparison with Traditional Laboratory Equipment

In the realm of material analysis, handheld alloy analyzers have revolutionized the way we conduct tests by offering a stark contrast to traditional laboratory equipment. This section delves into the comparative analysis of handheld alloy analyzers versus traditional laboratory equipment, focusing on aspects such as portability, ease of use, and adaptability to various testing environments.

Portability and Versatility

Handheld alloy analyzers stand out for their exceptional portability. Unlike bulky traditional lab equipment, these devices are compact and lightweight, designed to be carried to any testing site—be it a remote location, a manufacturing facility, or a construction site. This portability is a game-changer, enabling on-the-spot analysis without the need for transporting samples back to a central lab.

Moreover, the versatility of handheld analyzers is unparalleled. They can analyze a diverse range of sample types, including liquids, solids, powders, and films. This adaptability is crucial in fields such as environmental monitoring, geology, metallurgy, and pharmaceuticals, where sample types can vary significantly.

Speed and Efficiency

Speed is another significant advantage of handheld analyzers. Traditional lab equipment often requires lengthy preparation and analysis times, which can delay decision-making processes. In contrast, handheld XRF (X-ray Fluorescence) analyzers can deliver results in seconds. For instance, under specific conditions (8.5μA current, 38kV voltage, and 30 seconds test time), these devices can measure elements in alloys like 316 and provide detailed spectra showing clear peaks for various elements such as Cr, Mn, Fe, Co, Ni, and Mo. This rapid analysis capability is vital in industries where time-to-insight is critical.

Accuracy and Reliability

Despite their compact size, handheld analyzers are equipped with advanced technologies that ensure high accuracy and reliability. Features such as intelligent FP algorithms and standard curve methods enable these devices to achieve low detection limits and high measurement accuracy. This precision is on par with, if not better than, many traditional lab instruments.

Wide Detection Range and Rapid Quantitative Analysis

Handheld analyzers boast a wide detection range, applicable to various types of alloys including magnesium-based, aluminum-based, titanium-based, iron-based, and more. This broad applicability makes them indispensable tools across multiple industries. Additionally, their rapid quantitative analysis capability, often completing tests in just one second, significantly enhances operational efficiency and reduces resource consumption.

Convenience and Safety

The ease of operation is a hallmark of handheld analyzers. With user-friendly interfaces and straightforward menu navigation, even minimally trained personnel can operate these devices effectively. Safety features, such as material sensing functions and intelligent status display lights, coupled with safety linkage devices, ensure operator and instrument safety during use.

Application in Alloys and Beyond

The applications of handheld spectrometers extend beyond alloys, encompassing areas such as recycling and sorting, mineral testing, and new energy sectors. Their ability to analyze elements at low temperatures and in hard-to-reach locations, coupled with high-definition screen displays and one-button operation, makes them versatile and user-friendly.

Conclusion

In summary, handheld alloy analyzers offer a compelling alternative to traditional laboratory equipment by combining portability, speed, accuracy, and ease of use. Their adaptability to various testing environments and broad range of applications make them indispensable tools in modern material analysis. As technology continues to advance, these devices are poised to further enhance their capabilities, continuing to push the boundaries of what is possible in on-site material analysis.

Related Products

Related Articles

- Advanced Techniques in Coating Evaluation Using Electrolytic Cells

- Understanding Saturated Calomel Reference Electrodes: Composition, Uses, and Considerations

- The Architecture of Certainty: Mastering Control in Multifunctional Electrolytic Cells

- Comprehensive Guide to Handheld Soil Analyzers: Features, Benefits, and Applications

- Comprehensive Guide to Reference Electrodes: Types, Applications, and Selection Criteria