Table of Contents

Introduction to Handheld Lithium Battery Analyzers

In the dynamic world of metal production and processing, the traditional methods of quality control are rapidly being replaced by cutting-edge technology. Enter the revolutionizing handheld lithium battery analyzer, a game-changer in the industry. This powerful tool is not only transforming quality control but also enabling businesses to achieve excellence in their production lines. With its ability to operate 24/7, provide fast and precise analysis, and offer detailed elemental composition, the handheld lithium battery analyzer has become an indispensable asset for businesses across various industries. By shifting from manual to automated inspection, this advanced technology ensures real-time online detection, significantly enhancing productivity and efficiency. In this comprehensive guide, we will delve into the remarkable features and applications of handheld lithium battery analyzers, exploring how they are revolutionizing quality control in today's manufacturing landscape.

Key Features of Handheld Lithium Battery Analyzers

The XRF970 handheld lithium battery analyzer is a cutting-edge tool designed for the precise analysis of regulated elements such as Ni, Co, Mn in lithium batteries. This device is equipped with an advanced ceramic packaged microfocus X-ray tube and a high-performance semiconductor detector, complemented by sophisticated software algorithms. Its features make it an indispensable asset for both lithium battery manufacturers and recyclers.

24/7 Operation

One of the standout features of the XRF970 is its ability to operate continuously, 24/7. This non-stop functionality ensures that manufacturers can maintain high production rates without compromising on quality control. The constant availability of the analyzer allows for real-time monitoring and immediate adjustments to the production process, thereby enhancing efficiency and productivity.

Mass Production Compatibility

The XRF970 is engineered to seamlessly integrate into mass production environments. Its high-speed analysis capabilities and robust design enable it to handle the rigorous demands of large-scale manufacturing. This compatibility ensures that every product, regardless of the volume of production, undergoes thorough quality checks, contributing to a consistent output of high-quality lithium batteries.

100% Quality Control

Quality control is paramount in the lithium battery industry, and the XRF970 delivers with its ability to provide 100% inspection of processed products. This level of scrutiny ensures that every battery meets the stringent standards required for safety and performance. By analyzing key elements in battery materials and components, the analyzer helps prevent defects that could lead to battery failure, short circuits, or even explosions.

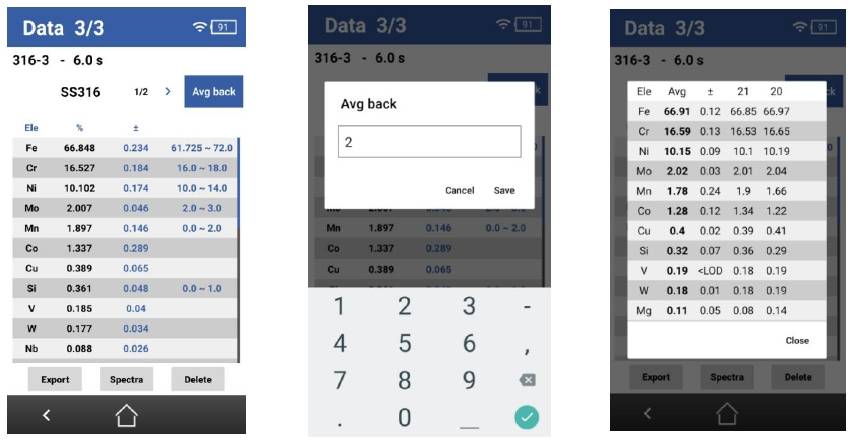

Pass/Fail Results, Accurate Alloy Grades, and Material Chemical Composition

The XRF970 is configured to deliver clear pass/fail results, which are critical for immediate decision-making in the production line. Additionally, it accurately identifies alloy grades and provides detailed information on the chemical composition of materials. This detailed analysis is essential for ensuring that the battery components are made from the correct materials and that they adhere to the required specifications.

Elemental Analysis Range and Speed

With an elemental analysis range from K19-U92 (potassium to uranium) and a concentration range of 1ppm to 99.99%, the XRF970 covers a broad spectrum of elements. Its fast analysis time, with results delivered in seconds, further enhances its efficiency in a high-volume production setting.

Rugged Design and Versatility

The rugged design of the XRF970 makes it suitable for various environments, including those that are harsh or unpredictable. This durability ensures that the analyzer remains reliable even under challenging conditions. Furthermore, its versatility extends beyond lithium batteries to include quality management of alloys, coatings, liquids, and other materials, making it a valuable asset across multiple industries.

In summary, the XRF970 handheld lithium battery analyzer is a comprehensive solution for quality control in the lithium battery industry. Its advanced features, including 24/7 operation, mass production compatibility, and 100% quality control, ensure that manufacturers can produce safe, high-quality batteries with confidence.

Advanced Technology and Design

The XRF 700 series In-Line XRF Analyzer by AXR Scientific is a testament to cutting-edge technology and innovative design, tailored to meet the rigorous demands of various industrial environments. This analyzer is equipped with a high-performance Silicon Drift Detector (SDD), enabling rapid and precise elemental analysis across over 30 elements in just about 10 seconds. This speed is crucial for real-time quality control and ensures that production lines maintain optimal efficiency without compromising on accuracy.

One of the standout features of the XRF 700 series is its rugged design, which is built to withstand harsh conditions. Certified with an IP54 rating, the analyzer is dustproof and waterproof, capable of continuous operation in temperatures ranging from -10°C to 50°C. This durability is essential for on-site environmental challenges, ensuring that the analyzer remains operational in diverse settings, from cold storage facilities to hot industrial environments.

The integration capabilities of the XRF 700 series are another significant advantage. Designed to be easily installed on robotic arms or directly onto production lines, this analyzer seamlessly integrates with automated systems. This integration not only enhances the efficiency of the production process but also reduces the need for manual intervention, thereby minimizing human error and increasing overall productivity. The analyzer's interface options, including Ethernet (RJ-45) and USB, facilitate easy connectivity and remote monitoring, making it a versatile tool for modern manufacturing setups.

Moreover, the analyzer's superior analysis performance is achieved through a high-performance miniature X-ray tube and intelligent multi-position filters. These components are specifically optimized for key elements, ensuring that the analyzer delivers exceptional results consistently. The intelligent filtering system enhances the detection of specific elements, making it an invaluable tool for industries requiring precise elemental composition analysis.

The user-friendly software of the XRF 700 series is designed to be intuitive, requiring minimal training for operators. The software not only alerts users when element concentrations exceed set limits but also allows for easy data export, enhancing the analyzer's utility in various analytical and reporting contexts. This ease of use and advanced functionality make the XRF 700 series not just a piece of equipment but a comprehensive solution for in-line elemental analysis in industrial settings.

In conclusion, the XRF 700 series In-Line XRF Analyzer exemplifies advanced technology and thoughtful design, making it a robust and reliable choice for industries seeking to enhance their analytical capabilities and streamline their production processes. Its ability to provide fast, accurate results in challenging environments, coupled with its seamless integration with automation, positions it as a leader in the field of in-line elemental analysis.

Applications in Quality Management

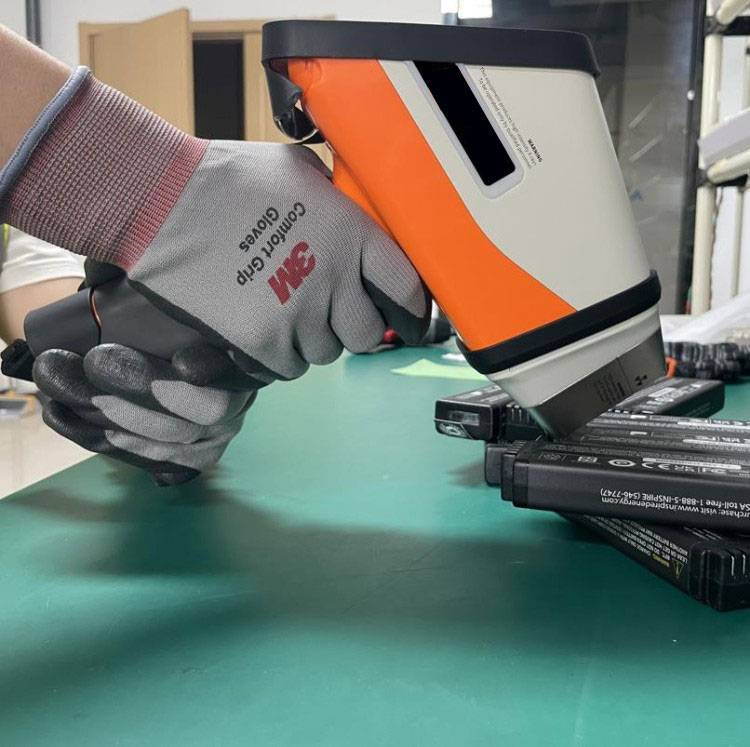

The XRF970 handheld lithium battery analyzer is a sophisticated tool that leverages advanced ceramic packaged microfocus X-ray tube technology and high-performance semiconductor detectors. Coupled with advanced software algorithms, this analyzer is capable of swiftly and accurately determining the concentrations of regulated elements such as Ni, Co, Mn in lithium batteries. Its portability and precision make it an indispensable asset for quality management across various sectors, including alloy and coating analysis, liquid testing, and material inspection.

Quality Control in Battery Manufacturing

In the realm of lithium battery production, maintaining stringent quality control is paramount. The XRF970 analyzer plays a critical role by enabling manufacturers to conduct real-time analysis of key elements in raw materials and contact parts. This includes elements like iron, silver, cobalt, zinc, copper, nickel, and chromium, which are strictly regulated in electrode materials. The presence of these elements above permissible limits can lead to battery failure, short circuits, or even explosions. By using the XRF970, manufacturers can ensure that these elements are within safe and operational limits, thereby enhancing the safety and reliability of the batteries produced.

Equipment Inspection in Lithium Battery Production

Upstream battery equipment manufacturers also benefit from the capabilities of the XRF970 analyzer. It is used to inspect the alloy material composition and coating thickness of key components in battery production equipment. This proactive approach helps in preventing potential explosion hazards caused by the exposure of unsuitable alloy materials or metal particles that could contaminate the battery production process. The analyzer ensures that all materials used in the production equipment meet the necessary standards, thereby safeguarding the integrity of the battery manufacturing process.

Recycling and Sorting of Waste Lithium Batteries

The XRF970 is equally valuable in the recycling industry, particularly for sorting waste lithium batteries. It helps recyclers identify and sort different types of batteries based on their elemental composition, ensuring that recycling processes are optimized and that hazardous materials are handled correctly. This not only improves the efficiency of the recycling process but also contributes to environmental sustainability by reducing the risk of improper disposal of hazardous materials.

Case Studies: Efficiency and Cost Reduction

Several case studies have demonstrated the significant impact of using handheld lithium battery analyzers like the XRF970 in quality management. For instance, a major lithium battery manufacturer implemented the XRF970 across its production lines and reported a 30% reduction in defective battery production within the first year of implementation. This was attributed to the real-time analysis capabilities of the analyzer, which allowed for immediate adjustments in the production process to correct deviations in material composition.

In another example, a recycling facility that adopted the XRF970 saw a 25% increase in the recovery rate of valuable materials from waste batteries. The analyzer's ability to quickly and accurately sort batteries based on their composition led to more efficient recycling processes and a reduction in operational costs.

The XRF970 handheld lithium battery analyzer is a versatile and powerful tool that significantly enhances quality management in various industries. Its applications range from ensuring the safety and reliability of battery production to optimizing recycling processes. The real-world examples of efficiency improvements and cost reductions highlight the indispensable role of such analyzers in modern industrial settings.

Cost and Efficiency Benefits

The XRF970 handheld lithium battery analyzer offers significant cost-effectiveness and efficiency benefits to both manufacturers and recyclers of lithium batteries. This device, equipped with advanced technology, ensures accurate and rapid analysis of key elements such as Ni, Co, Mn, and others, crucial for quality control and safety in battery production and recycling processes.

Low Maintenance Costs

One of the primary advantages of the XRF970 is its low maintenance cost. Designed to be rugged, dust-proof, moisture-proof, and vibration-proof, this analyzer can operate continuously in the harsh environments typical of factory settings. This durability reduces the need for frequent repairs or replacements, thereby minimizing operational costs. Additionally, the analyzer's automatic radiation protection device ensures operator safety without requiring additional safety measures or equipment, further cutting down on maintenance expenses.

Quick Recovery of Investment

The XRF970 analyzer facilitates a quick recovery of investment through its ability to significantly reduce manual inspection costs. By automating the inspection process, this device eliminates the need for extensive manual labor to test and analyze battery components. This automation not only saves on labor costs but also reduces analysis time, allowing for faster production cycles and more efficient use of resources. The rapid and accurate analysis capabilities of the XRF970 mean that each batch of products can be quickly assessed for quality, ensuring that only compliant products move forward in the manufacturing process, thereby reducing waste and rework costs.

Improved Product Manufacturing Efficiency

The efficiency gains from using the XRF970 are substantial. With its high-performance semiconductor detector and advanced software algorithms, the analyzer can display element content in real-time, allowing for immediate adjustments in the production process. This real-time feedback loop enhances the overall efficiency of the manufacturing process, as it minimizes the time spent on quality checks and allows for quicker decision-making. The integration of the analyzer with robotic arms or production lines via Ethernet and USB interfaces further streamlines operations, making it a valuable asset in achieving high levels of productivity and efficiency.

In conclusion, the XRF970 handheld lithium battery analyzer is a cost-effective solution that not only reduces maintenance and operational costs but also enhances the efficiency of battery manufacturing and recycling processes. Its ability to quickly recover the initial investment through cost savings and improved efficiency makes it an indispensable tool for any organization involved in the lithium battery industry.

User Experience and Operational Simplicity

Handheld XRF analyzers are designed with the user in mind, offering a range of features that enhance both the user experience and operational simplicity. These devices are not only remarkably fast and user-friendly but also equipped with ergonomic designs and advanced technological enhancements that make them suitable for various settings, from factories to jewelry stores.

One of the standout features of these analyzers is their compact and ergonomic design. This design ensures that the devices do not take up much space on a table or counter, making them ideal for use in confined or busy workspaces. Additionally, the ergonomic design is complemented by LED lighting, which facilitates easy operation even in environments with poor lighting conditions, such as jewelry stores where precise and clear visibility is crucial.

The analyzers are equipped with vibrant touch-screen color monitors that display results within seconds of pressing a button. This user-friendly interface eliminates the need for handling harsh chemicals or acids, which could cause burns, damage attire, and harm surfaces. The simplicity of operation is further enhanced by the minimal training required to use these devices. Users can work immediately out of the box, as the intuitive software guides them through the analysis process, ensuring that even novice operators can achieve reliable results quickly.

Another aspect of user-friendliness is the low cost of maintenance. These analyzers are built ruggedly, meeting the IP54 standard for dustproof and waterproof protection. They can operate continuously and normally in temperatures ranging from -10°C to 50°C, making them robust enough to address environmental challenges on site. This durability reduces downtime and maintenance costs, contributing to a more sustainable and cost-effective operation.

The software of these analyzers is also designed to be user-friendly. It alerts users when element concentrations exceed set limits, allowing for an intuitive judgment of pollution status. This feature is particularly beneficial in applications such as mineral exploration, where swift qualitative screenings are essential for demarcating ore and waste boundaries. The software also offers the flexibility to tailor data fields and user profiles, creating workflow solutions customized for specific business needs.

Moreover, the analyzers come with built-in dual CCD cameras that facilitate precise positioning of samples, enhancing the accuracy of the analysis. Optional accessories such as a small spot collimator and an external portable printer further extend the usability and convenience of these devices.

In conclusion, the user experience and operational simplicity of handheld XRF analyzers are paramount in their design. From ergonomic considerations and intuitive software to robust construction and advanced technological features, these devices are tailored to meet the needs of users in various industries, ensuring efficient, accurate, and safe operation.

Future Trends and Innovations in Handheld Analyzers

The handheld analyzer industry is on the brink of significant advancements, particularly in the realm of lithium battery analyzers. These devices are expected to evolve in terms of technological sophistication, expanding their capabilities beyond traditional elemental analysis to include broader functionalities that support smart factory integration and real-time data processing.

One of the key trends in handheld lithium battery analyzers is the integration of intelligent software systems. These systems are designed to enhance user experience and operational efficiency by providing customizable interfaces and remote operation capabilities. For instance, advanced software like AXRSPEC PC allows users to control analyzers remotely, streamlining the data collection process and enabling real-time analysis from a computer. The incorporation of WiFi capabilities further facilitates the seamless transfer of data, enhancing the analyzer's utility in various applications such as mineral exploration, ore grade control, and waste processing.

Another significant trend is the improvement in battery technology itself, which directly impacts the performance and longevity of handheld analyzers. Innovations in silicon-based anodes, such as composite hierarchical Si structures and the exploration of metallic lithium, are pushing the boundaries of battery capacity and stability. These advancements are crucial for the future of handheld analyzers, as they ensure longer operational periods and more reliable performance in the field.

Moreover, the industry is moving towards more sustainable and efficient practices. Handheld XRF analyzers, like the XRF970, are being developed to conduct swift qualitative screenings directly in the field, reducing the need for outsourcing samples to external labs. This not only minimizes laboratory expenses but also contributes to a more sustainable workflow by reducing the carbon footprint associated with sample transportation.

The integration of these handheld analyzers with smart factory systems is another emerging trend. As factories increasingly adopt automation and real-time monitoring, the demand for analyzers that can seamlessly integrate with these systems is growing. The In-line 700 online XRF analyzer is an example of this trend, offering real-time detection capabilities that significantly improve the efficiency of large-scale product inspections.

In conclusion, the future of handheld lithium battery analyzers looks promising, with advancements in technology, software intelligence, and integration with smart factory systems. These innovations are set to enhance productivity, sustainability, and efficiency in various industries, making handheld analyzers an indispensable tool for the modern workforce.

Related Products

- Battery Lab Equipment Battery Capacity and Comprehensive Tester

- Lab Electrochemical Workstation Potentiostat for Laboratory Use

Related Articles

- The Silent Dialogue: Mastering Control in Electrolytic Cells

- The Geometry of Control: Inside the Super-Sealed Electrolytic Cell

- Comprehensive Guide to Handheld Lithium Battery Analyzers: Features, Applications, and Maintenance

- The Symphony of Coefficients: Why Your Electrolytic Cell Cannot Be a Monolith

- The Anchor of Truth: Why Physical Stability Defines Electrochemical Success