In short, yes. Autoclave emissions can be hazardous, but the specific risks depend entirely on what is being sterilized and how the machine is operated. The most immediate and common hazard is superheated steam, which can cause severe burns, but emissions can also contain hazardous biological or chemical agents if proper procedures are not followed.

The primary hazards from an autoclave do not come from the machine itself, but from its contents. Understanding that you are managing a system—not just a piece of equipment—is the key to mitigating risks from steam, infectious aerosols, and chemical vapors.

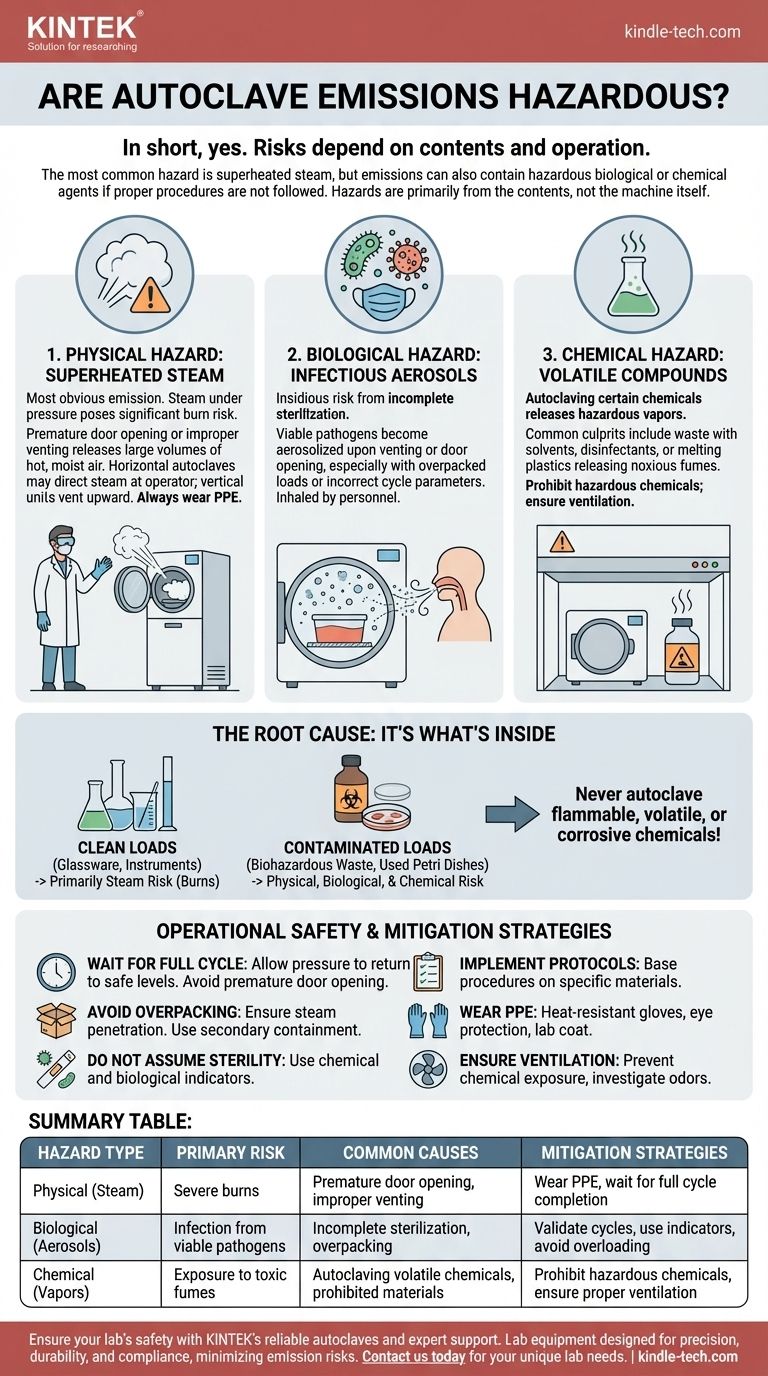

Deconstructing Autoclave Emissions: The Three Core Hazards

The term "emissions" from an autoclave can refer to several distinct outputs, each with its own risk profile. Safe operation requires understanding and controlling all three.

The Physical Hazard: Superheated Steam

The most obvious emission is steam. This isn't just hot water vapor; it's steam under pressure that is often superheated, posing a significant burn risk.

When a cycle finishes, the chamber is still pressurized. Opening the door prematurely can release this steam violently. Even during a normal depressurization phase, a large volume of hot, moist air is vented, which is why proper personal protective equipment (PPE) is non-negotiable.

The design of the autoclave can influence this risk. For example, a horizontal autoclave with a door opening outward directs steam directly at the operator if opened incautiously, while a top-loading vertical unit may vent steam upward.

The Biological Hazard: Infectious Aerosols

This is a more insidious risk. If an autoclave cycle is incomplete or fails, the microorganisms inside are not fully inactivated.

When the autoclave vents or the door is opened, these viable pathogens can become aerosolized—suspended in tiny airborne droplets—and inhaled by personnel. This can happen if the autoclave is overpacked, preventing proper steam penetration, or if the cycle parameters (time, temperature, pressure) are incorrect for the load.

The Chemical Hazard: Volatile Compounds

Never assume that only biological materials are a risk. Autoclaving certain chemicals or materials can release hazardous vapors.

Common examples include sterilizing waste containing trace amounts of solvents, disinfectants, or bleach. These chemicals can vaporize and be released into the lab environment upon venting. Similarly, some plastics not rated for autoclaving can melt or degrade, releasing noxious fumes.

The Root Cause: It's What's Inside

The level of hazard is directly proportional to the contents of your load. An autoclave sterilizing clean laboratory glassware presents a fundamentally different risk profile than one processing infectious medical waste.

Clean vs. Contaminated Loads

A load of new, clean glassware or stainless steel instruments will primarily only emit steam. The risk is almost entirely physical (burns).

A load of biohazardous waste, used petri dishes, or animal bedding presents a physical, biological, and potentially chemical risk. The potential for foul odors, which can indicate incomplete sterilization or off-gassing, is also much higher.

Inappropriate Materials

As a rule, only materials explicitly rated for autoclaving should be processed. Standard carbon steel instruments can be damaged by the high-pressure moisture, and many plastics will melt.

Beyond damaging the items, autoclaving prohibited materials is a significant safety hazard. Never autoclave flammable, volatile, or corrosive chemicals like solvents, bleach, or radioactive materials.

Understanding the Trade-offs: Operational Safety vs. Inefficiency

Most autoclave-related incidents are not due to machine failure, but to human error, often stemming from a desire to save time.

The Danger of Rushing the Cycle

Operators must wait for the autoclave to complete its full cycle, including the "exhaust" or "venting" phase, which allows pressure to return to a safe level. Opening the door while the chamber is still pressurized is the leading cause of steam burns.

The Risk of Improper Loading

Overpacking an autoclave is a false economy. It prevents steam from reaching all surfaces, which dramatically increases the risk of an incomplete sterilization cycle and the subsequent release of biological aerosols. Always use secondary containment like autoclavable pans to contain any spills.

The Fallacy of Assuming Sterility

Do not assume a completed cycle equals a sterile load. Use chemical indicator strips in every load to show it has reached temperature and run periodic biological indicator tests (spore tests) to truly validate that your autoclave is killing microorganisms effectively.

Ensuring Safety in Your Autoclave Operations

To mitigate these hazards, you must implement strict operational protocols. Base your procedures on the specific materials you are processing.

- If your primary focus is personnel safety from steam: Always wear heat-resistant gloves, eye protection, and a lab coat, and stand back when opening the door after a cycle is complete.

- If your primary focus is containing biological risk: Use validated cycle times, ensure loads are not overpacked, use secondary containment, and regularly verify performance with biological indicators.

- If your primary focus is preventing chemical exposure: Maintain a strict policy against autoclaving prohibited chemicals, ensure the autoclave room is well-ventilated, and investigate any unusual odors immediately.

By implementing and adhering to rigorous safety protocols, you transform the autoclave from a potential hazard into an essential and reliable safety tool.

Summary Table:

| Hazard Type | Primary Risk | Common Causes | Mitigation Strategies |

|---|---|---|---|

| Physical (Steam) | Severe burns | Premature door opening, improper venting | Wear PPE, wait for full cycle completion |

| Biological (Aerosols) | Infection from viable pathogens | Incomplete sterilization, overpacking | Validate cycles, use indicators, avoid overloading |

| Chemical (Vapors) | Exposure to toxic fumes | Autoclaving volatile chemicals, prohibited materials | Prohibit hazardous chemicals, ensure proper ventilation |

Ensure your lab’s safety with KINTEK’s reliable autoclaves and expert support. Whether you’re sterilizing glassware, biohazardous waste, or lab instruments, KINTEK provides lab equipment designed for precision, durability, and compliance. Our autoclaves help you minimize emissions risks with validated performance and user-safe features. Contact us today to find the right autoclave solution for your laboratory’s unique needs!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

People Also Ask

- How is an autoclave utilized in antimicrobial experiments? Ensure Precise Nanoparticle Research Integrity

- What is the necessity of using a steam autoclave for dental alloys? Ensure Pure Bacterial Adhesion Data

- Why is the prevention of air entrapment critical for the autoclave sterilization process? Ensure 100% Sterility Today

- What role does an autoclave play in remediation experiments? Ensure Precision by Eliminating Biological Noise

- What are the standard operating parameters for an autoclave? Master Temperature, Pressure, and Time for Sterilization