In short, yes. An autoclave is safe when its engineered safety features are intact and, most importantly, when it is operated by a trained user following strict protocols. These devices use high-pressure, high-temperature steam to achieve sterilization, and this combination of pressure and heat is inherently dangerous if not managed with care and respect.

The safety of an autoclave is not a feature of the machine alone; it is a system that depends equally on engineered controls and disciplined operator procedure. The vast majority of incidents are caused by human error, not catastrophic equipment failure.

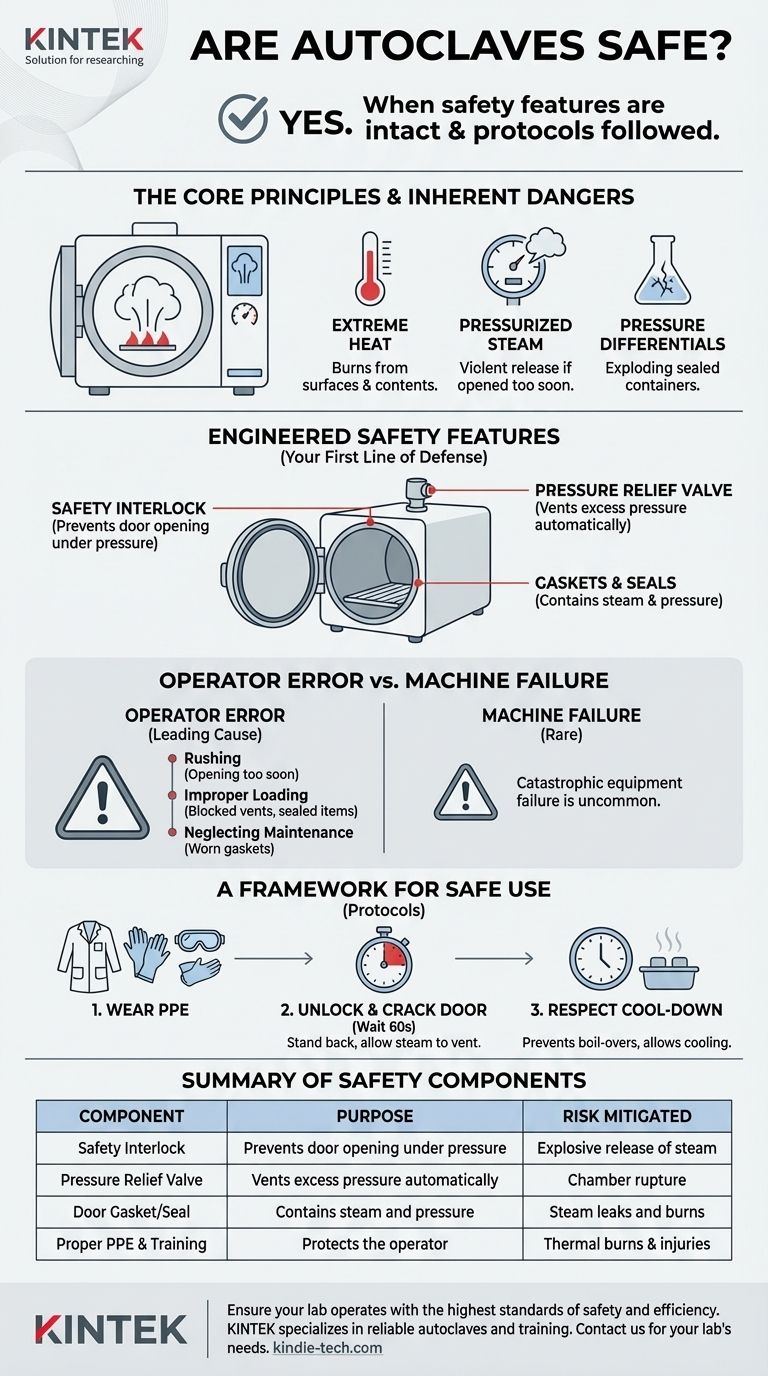

The Core Principles of Autoclave Operation

To understand the risks, you must first understand how an autoclave works. It is fundamentally a pressure chamber that introduces steam to elevate the temperature far beyond boiling point, typically to 121°C (250°F) or higher, to sterilize equipment and supplies.

The Inherent Dangers

The process relies on three physical forces, each presenting a distinct hazard:

- Extreme Heat: Surfaces of the autoclave, including the door and chamber walls, become incredibly hot and can cause severe thermal burns on contact. The contents remain dangerously hot long after the cycle finishes.

- Pressurized Steam: During the cycle, the chamber is under immense pressure. If the door were opened under pressure, it would result in a violent, explosive release of scalding steam. Even after the pressure gauge reads zero, residual steam can cause serious burns.

- Pressure Differentials: Loading sealed containers or improper glassware can cause them to explode inside the chamber during the pressure and temperature changes.

Engineered Safety Features: Your First Line of Defense

Modern autoclaves are built with multiple safety mechanisms designed to prevent the most common causes of catastrophic failure.

The Safety Interlock

This is the most critical feature. An interlock system physically prevents the door from being opened as long as the chamber is pressurized. It ensures the cycle must be complete and pressure normalized before a user can access the chamber.

The Safety Valve

This is a mechanical failsafe. If the autoclave’s electronic controls were to malfunction and pressure were to build beyond the machine's designated limit, a pressure relief valve automatically opens to vent steam and prevent a rupture.

Gaskets and Seals

The rubber or silicone gasket that seals the door is essential for containing pressure. While simple, its integrity is paramount. A worn, cracked, or dirty gasket can lead to dangerous leaks of high-temperature steam.

Understanding the Trade-offs: Operator Error vs. Machine Failure

While modern autoclaves have robust safety features, they cannot eliminate the risks associated with improper use. Operator error is, by a significant margin, the leading cause of autoclave-related injuries.

The Danger of Rushing

The most common mistake is opening the door too soon. Users must wait for the pressure to return to zero and allow for a cool-down period (often 10 minutes or more). Opening the door immediately, even at zero pressure, can cause boiling liquids to overflow or release a large plume of residual steam.

Improper Loading Techniques

Overloading the chamber can block steam circulation and vents, leading to failed sterilization and potential pressure issues. Using sealed, airtight containers is exceptionally dangerous, as the trapped, heated air will expand and can cause the container to explode.

Neglecting Basic Maintenance

Safety is compromised when operators fail to perform routine checks. This includes inspecting the door gasket for wear, cleaning the chamber drain screen to prevent clogs, and ensuring the unit receives its scheduled professional servicing.

A Framework for Safe Autoclave Use

Adopting a disciplined, protocol-driven approach is the only way to guarantee safety.

Before starting a cycle, always wear your Personal Protective Equipment (PPE). This includes a lab coat, eye protection, and closed-toed shoes. Use heat-resistant gloves when handling hot items.

The Unlocking and Opening Procedure

This is the moment of highest risk. Even after the cycle is complete and the pressure gauge reads zero, stand back from the door. Unlock it, but open it only a small crack for 60 seconds. This allows trapped residual steam to vent safely away from your face and body. For horizontal autoclaves with doors that swing outward, this prevents a blast of steam directly at the operator.

Respect the Cool-Down Period

Never remove items immediately. Liquids, in particular, can remain superheated and may boil over violently if moved too soon. Let all items cool for a sufficient period inside the chamber or on a designated heat-proof surface after removal.

Making the Right Choice for Your Goal

Your approach to autoclave safety should be tailored to your role.

- If your primary focus is routine operation: Your priority is mastering the cool-down period and the slow-opening door technique, always supported by proper PPE.

- If your primary focus is lab management: Implement mandatory, hands-on training for all users, post clear step-by-step instructions at the machine, and enforce a strict maintenance and service log.

- If your primary focus is purchasing a new unit: Prioritize models with redundant safety interlocks, clear and easy-to-read pressure displays, and a design that helps deflect steam away from the user upon opening.

Ultimately, an autoclave's safety is a direct result of the operator's knowledge and discipline.

Summary Table:

| Safety Component | Purpose | Key Risk Mitigated |

|---|---|---|

| Safety Interlock | Prevents door opening under pressure | Explosive release of steam |

| Pressure Relief Valve | Vents excess pressure automatically | Chamber rupture |

| Door Gasket/Seal | Contains steam and pressure | Steam leaks and burns |

| Proper PPE & Training | Protects the operator | Thermal burns and other injuries |

Ensure your lab operates with the highest standards of safety and efficiency. KINTEK specializes in reliable laboratory autoclaves and consumables, designed with robust safety features to protect your team and your research. Our experts can help you select the right equipment and provide the training support you need. Contact us today to discuss your lab's sterilization needs and create a safer working environment.

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Laboratory Test Sieves and Sieving Machines

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- How do high-pressure autoclaves facilitate the synthesis of mesoporous hydroxyapatite powders? Optimize Your Biomaterials

- How do high-pressure autoclave systems simulate nuclear reactor environments? Precision sCO2 Corrosion Studies

- What is the autoclave temperature for sterilization? Master the 121°C Standard for Guaranteed Sterility

- What role do laboratory autoclaves play in pectin extraction? Optimize Prebiotic Yield from Citrus and Apple Biomass

- What is the purpose of an autoclave quizlet? Achieve Absolute Sterility for Safety and Integrity

- What is the principle of autoclave quizlet? Master the Science of Steam Sterilization

- What are the pros and cons of autoclave? Unlock Fast, Economical Sterilization

- Is a retort a pressure vessel? The Critical Safety Classification for Your Sterilization Process