Yes, absolutely. Aluminum is one of the most common and versatile metals deposited using sputtering. This physical vapor deposition (PVD) technique is widely used in industries ranging from semiconductor manufacturing for creating electrical interconnects to producing reflective coatings for mirrors and decorative finishes.

While sputtering aluminum is a standard industrial process, achieving a high-quality, pure metallic film is not trivial. Success hinges on meticulously controlling the vacuum environment to overcome aluminum's high reactivity with oxygen.

How Sputtering Creates a High-Quality Aluminum Film

Sputtering is a highly controlled process that deposits thin films with excellent physical properties. It offers distinct advantages for depositing reactive metals like aluminum compared to other methods like thermal evaporation.

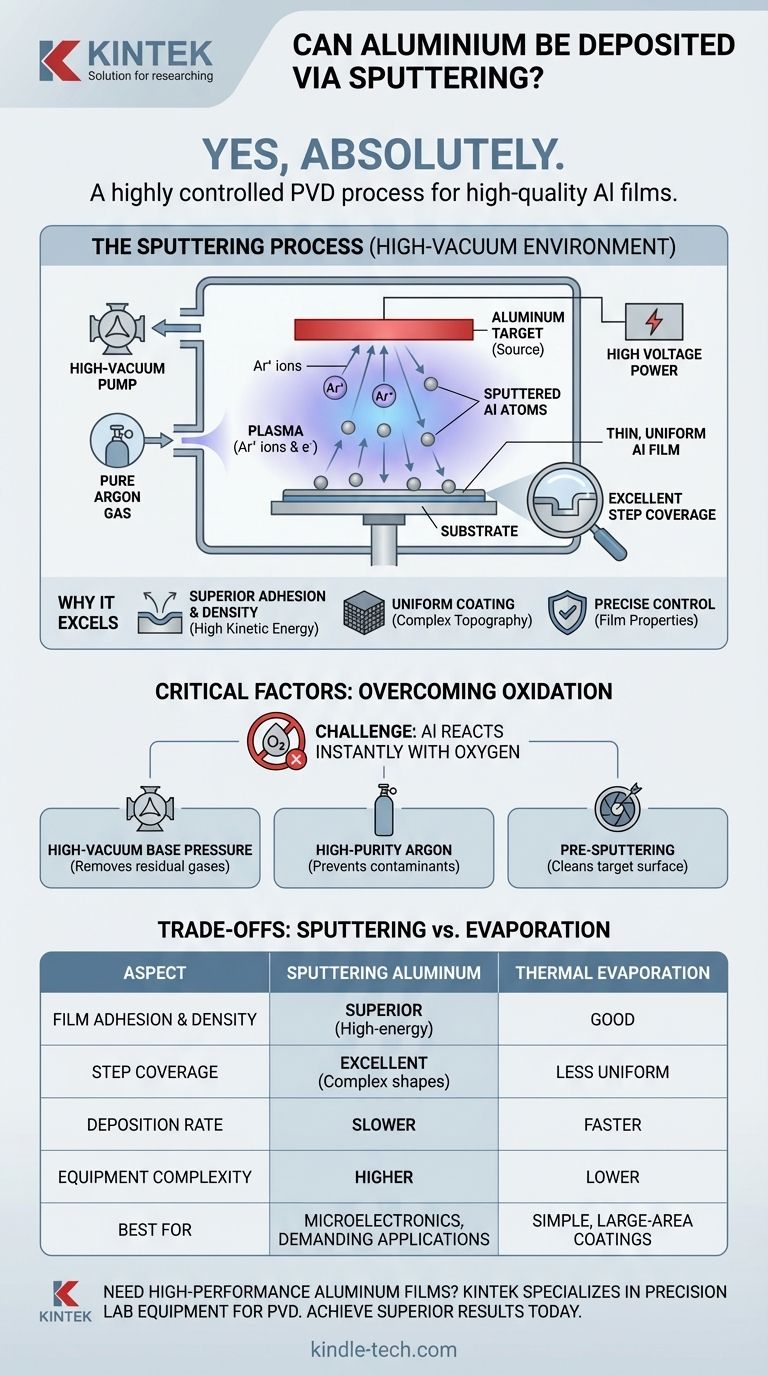

The Sputtering Process in Action

The process begins by creating a high vacuum in a sealed chamber. An inert gas, most commonly argon, is introduced at a low pressure.

A high voltage is then applied to the solid aluminum source material, known as the target. This ignites the argon gas into a plasma, an energized state of matter containing positive argon ions and free electrons.

These high-energy argon ions are accelerated into the aluminum target, striking its surface and dislodging, or "sputtering," individual aluminum atoms. These atoms then travel through the chamber and deposit onto your substrate, gradually building a thin, uniform film.

Why Sputtering Excels for Aluminum

Sputtered aluminum atoms arrive at the substrate with significantly higher kinetic energy than evaporated atoms. This results in a film that is denser and has superior adhesion to the underlying surface.

This process also provides excellent step coverage, meaning it can uniformly coat surfaces with complex topography, such as the microscopic trenches found in integrated circuits.

Critical Factors for Sputtering Aluminum

The primary challenge when sputtering aluminum is its extreme affinity for oxygen. Even trace amounts of oxygen or water vapor in the vacuum chamber can compromise the film's quality.

The Challenge of Oxidation

Aluminum reacts instantly with oxygen to form aluminum oxide (Al₂O₃). If this happens during deposition, it can create a film with high electrical resistance, poor reflectivity, and different mechanical properties than pure aluminum.

Achieving a High-Vacuum Environment

To prevent oxidation, the sputtering system's chamber must be pumped down to a very low base pressure before introducing the argon gas. This removes residual gases, especially oxygen and water. High-vacuum pumps like cryopumps or turbomolecular pumps are essential for this task.

The Role of Argon Purity

The purity of the argon process gas is also critical. Using high-purity (e.g., 99.999%) argon ensures that you are not inadvertently introducing oxygen or moisture into the chamber along with your process gas.

Target Conditioning

Before starting the actual deposition, it is standard practice to pre-sputter the aluminum target for several minutes with a shutter protecting the substrate. This cleans the target surface, removing any native oxide layer that formed while it was exposed to air.

Understanding the Trade-offs: Sputtering vs. Evaporation

Sputtering is not the only method for depositing aluminum; thermal evaporation is another common technique. The choice between them depends entirely on your application's requirements.

Film Adhesion and Density

Sputtering is superior. The higher energy of sputtered atoms creates a denser, more durable film with significantly better adhesion, making it ideal for applications that require robust mechanical performance.

Deposition Rate and Simplicity

Evaporation often has the edge. For simple, large-area coatings where adhesion is less critical, thermal evaporation can be faster and utilize simpler, less expensive equipment.

Coating Complex Shapes

Sputtering provides better coverage. The way sputtered atoms scatter in the plasma allows for more uniform coating over non-flat surfaces, which is a major advantage in microfabrication.

Film Purity and Damage

This is a nuanced trade-off. Evaporation can sometimes produce a slightly purer film because there is no plasma involved, which can potentially heat or cause radiation damage to very sensitive substrates. However, a well-controlled sputtering process can also yield extremely high-purity films.

Making the Right Choice for Your Aluminum Film

Your final decision must be guided by the specific properties your film needs to possess.

- If your primary focus is robust adhesion and film density for demanding applications like microelectronics: Sputtering is the superior choice due to the higher energy of the deposited atoms.

- If your primary focus is rapid, low-cost deposition on a simple, flat surface: Thermal evaporation may be a more efficient and economical alternative.

- If your primary focus is uniformly coating a substrate with complex surface features: The conformal nature of sputtering offers a distinct and necessary advantage.

By carefully managing the vacuum quality and process parameters, sputtering provides a powerful and precise method for engineering high-performance aluminum films.

Summary Table:

| Aspect | Sputtering Aluminum | Thermal Evaporation |

|---|---|---|

| Film Adhesion & Density | Superior (High-energy atoms) | Good |

| Step Coverage | Excellent for complex shapes | Less uniform |

| Deposition Rate | Slower | Faster |

| Equipment Complexity | Higher | Lower |

| Best For | Microelectronics, demanding coatings | Simple, large-area coatings |

Need a high-performance aluminum film for your lab?

KINTEK specializes in precision lab equipment and consumables for sputtering and other PVD processes. Whether you're in semiconductor manufacturing, optics, or materials R&D, we provide the solutions to achieve superior film adhesion, purity, and uniformity.

Contact our experts today to discuss how we can support your laboratory's specific coating challenges and help you select the right equipment for depositing high-quality aluminum and other materials.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Evaporation Boat for Organic Matter

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

People Also Ask

- Why carbon nanotubes are better than graphene? Matching Material Geometry to Your Engineering Challenge

- What are the properties and uses of mechanical thin films? Enhance Durability and Wear Resistance

- Can you coat something in diamond? Unlock Unmatched Hardness and Thermal Conductivity

- What is a thin film in nano science? The Engineered Layer Powering Modern Technology

- What are the advantages of using the chemical Vapour deposition approach for CNT production? Scale Up with Cost-Effective Control

- What is sputtering in physical vapor deposition? A Guide to Atomic-Level Thin Film Coating

- What is CVD lab grown diamond? A Real Diamond Grown in a Lab

- What is the resistance of CVD graphene? Achieve Superior Conductivity and Transparency